Both contemporary machine-made and hand-made techniques can be used to make rope chains. However, rope chains made by rope chain-making machines with QCW laser welding systems are produced faster, more efficiently, and generally more consistent in quality and appearance. These devices feed a metal wire through a series of rollers and die that twist it and form it into the proper chain pattern. Machine-made rope chains are becoming increasingly popular in many commercial jewellery applications because they are so delicate and precise that they gradually replace traditional hand-made techniques.

QCW Laser Rope Chain-Making Machine

The machine can make single or double chains, triple cable chains, curb chains, and Cuban chains. It has a chain presence sensor, chain collection plate, automatic lubrication system, speed controller, and fixed spool. Machine-made chains work faster and are more stable than hand-made chains.

Laser Source Comparison

| QCW laser source | VS | YAG laser source |

| Small size, air-cooled | volume | Covers an area of large complex water cooling system |

| Electro-optical conversion rate ≥30% | The energy consumption | Electro-optical conversion rate≤3% |

| Maintenance-free, basically no consumable | Use cost | There are consumables, and late use cost is high |

| All-fiber design | Structure and stability | Free optical space transmission |

| Gold, silver, copper, stainless steel | welding material | Gold, stainless steel |

| No power attenuation for 3-4years | The service life of the | Annual maintenance is required |

| 34KG | Weight | 120 kg |

Technical Parameters Comparison

| Parameter | QCW laser | YAG laser |

| Laser power | 60W /100w | 100W |

| Single pulse energy | 6J/10J(10ms effective) | 20J |

| Laser peak output | 0.6K/1.0kw | 4kw(5ms effective) |

| frequency/second | 1HZ-20khz | 1hz-50hz |

| pulse width | 0.05ms-20ms | 0.05ms-20 ms |

| working mode | pulse/modulation < | pulse |

| Energy fluctuation | 1.5% | 士3% |

| Optical fiber core | 50um,100um,150um,200um,300um | 300um/400um |

| Optical fiber output number/connector | 1-2 channel /RQB | 1-2 channels /D80 |

| Spectroscopic methods | Time splitting & Energy splitting | Time spectrum & energy spectrum |

| Aiming and positioning mode | Semiconductor red laser | Diode indicating red light |

| type of cooling | air-cooled | water-cooled |

| Power consumption | 400W | 1.2KW |

| power requirements | AC220V, 50160HZ | AC220V,50/60HZ |

| Dimensions L*W*H(mm ) | 455 *418*165/515*483*230 | 950*250*1080 |

| Diameter of laser welding spot | 0.2-1.0MM | 0.4-1.5mm |

| control mode | 7-inch Man-machine page | 5-inch Man-machine page |

| Weld control mode | Arbitrary waveform slowly rises and falls & gets | Gently slow down |

| Photoelectric conversion efficiency | ≥30% | ≤3% |

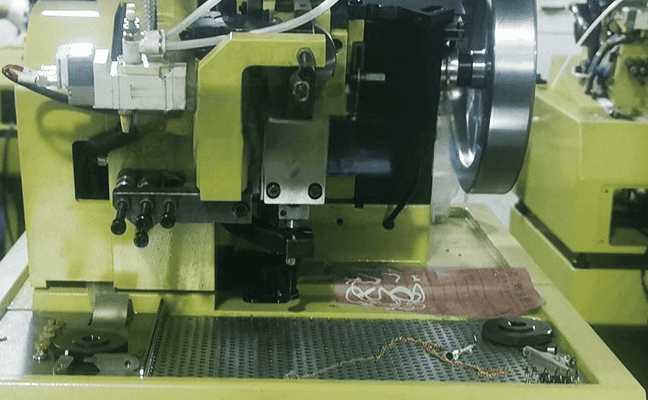

QCW Laser Rope Chain Machine Details

Chain falling system

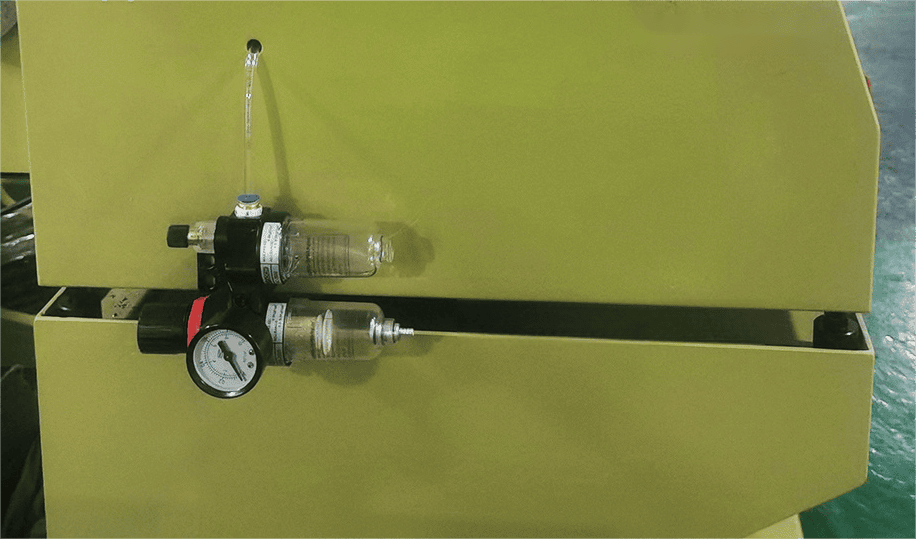

Gas controller

Auto lubrication system

Speed controller

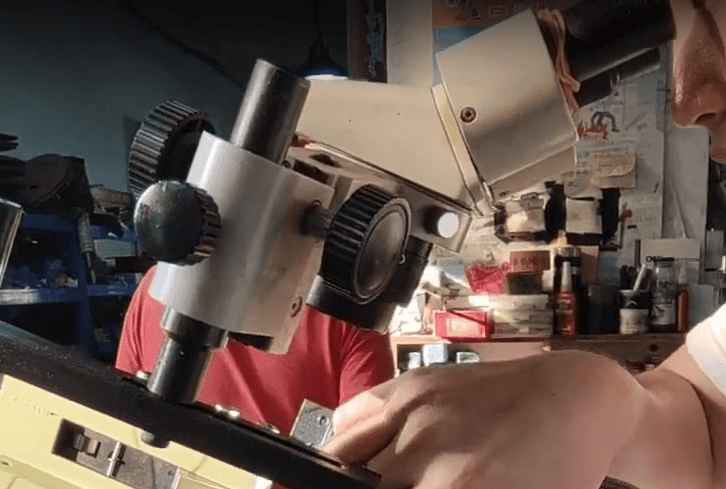

Observe system

QCW Laser Rope Chain Machine Features

1. Can be equipped with a 90-degree laser head or a straight head;

2. The point energy distribution is uniform and stable, without dragging;

3. Can weld stainless steel, K gold, 925 silver, and pure gold chains with a diameter of 0.12-0.6mm;

4. Non-contact processing, stress-free, noise-free, and environmentally friendly, it is green processing;

5. High laser energy density, small thermal effect area, not easy to deform, less or no subsequent processing;

7. High-quality laser beam, high conversion efficiency, and fast welding speed;

8. Good welding quality, smooth and beautiful appearance;

9. The welding point is pollution-free, and the strength and toughness of the weld are at least equal to or more substantial than the parent material;

10. Various input and output signals can quickly realize the machine’s automated and assembly line production.

QCW Laser Rope Chain Machine Instructions

1. Adjust the spiral, pin, horizontal knife, vertical knife and pliers; pull the ring to the appropriate position; insert the wire into the spiral and position it with the pin

2. Adjust the pliers to clamp the spiral

3. Adjust the horizontal knife and vertical knife to cut the ring

4. Adjust the pull ring to connect

5. Adjust the air nozzle to the appropriate position

6. Adjust the laser point to the appropriate position for welding

7. Pass through the welding ring

Service & Commitment

After-Sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality Control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM Service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms Of Payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document Support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.