6 Axis Robot Arm Laser Cutting Machine Introduction

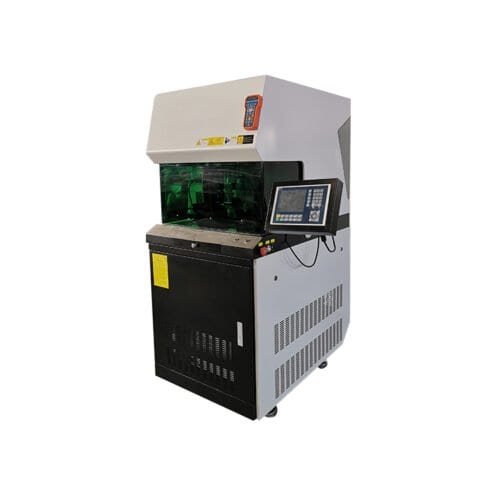

Are you planning to buy or customize a 6-axis robotic arm automatic metal laser cutting machine? The DAG 6-axis robotic arm system automatic metal fibre laser cutting machine has excellent versatility and power, with optional laser powers of 1000W, 1500W, 2000W and 3000W, equipped with a servo motor drive system, using the servo motor brand “servo”, the cutting machine ensures high precision and smooth operation, providing an excellent user experience. The laser cutting machine can process various products, including metal plates and tubes, and performs cutting functions well with high precision and high efficiency. The machine is cost-effective and worth having!

Technical Parameters

| Laser source | Raycus/ IPG /nLight/MAX optional |

| Output power of laser source | 1000W 1500W 2000W 3000W optional |

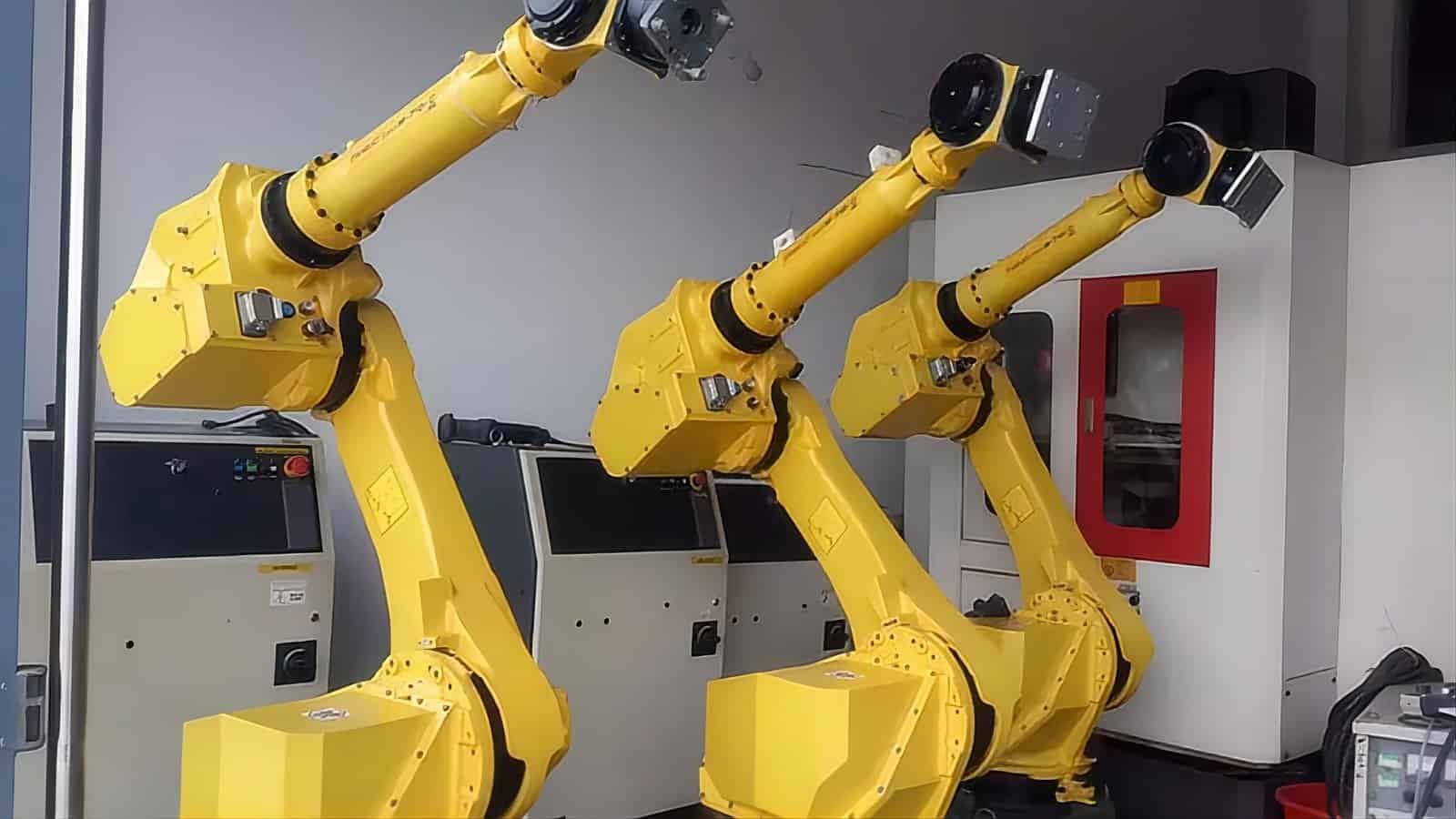

| Robot arm | Yaskawa/KUKA / ABB / FANUC |

| NUMBER OF AXES | 6 |

| PAYLOAD | 12 kg |

| MAX. WORKING RANGE | 1,440 mm |

| REPEATABILITY | 0.02 mm |

| WEIGHT | 150 kg |

| POWER SUPPLY | 1.5 kVA |

| S AXIS | 260 °/sec |

| L AXIS | 230 °/sec |

| U AXIS | 260 °/sec |

| R AXIS | 470 °/sec |

| B AXIS | 470 °/sec |

| T AXIS | 700 °/sec |

| MOUNTING OPTIONS | Ceiling, Wall, Floor |

International Top Brand Robotic Arm

Equipped with a gantry to expand the processing space and ensure the flexibility of the cutting head.

6-Axis Robot Arm Laser Cutting Machine Advantages

The 6-axis robotic laser cutting machine can cut materials with non-standard shapes, has a six-axis feed function, and can cut 360 degrees. It can also cut some non-standard materials, such as materials with fixed geometric shapes and angles.

1. Laser source: A high-performance fiber laser is used, which is highly efficient and has a low comprehensive use cost.

2. The robot arm adopts a world-renowned robot brand. The robot is agile, powerful, and has built-in fast movement, which can improve path accuracy and shorten cycle time. The robot software can effectively detect the internal load of the robot, overload protection, and extend service life—flexible integration, flexible production, only control, compact and efficient.

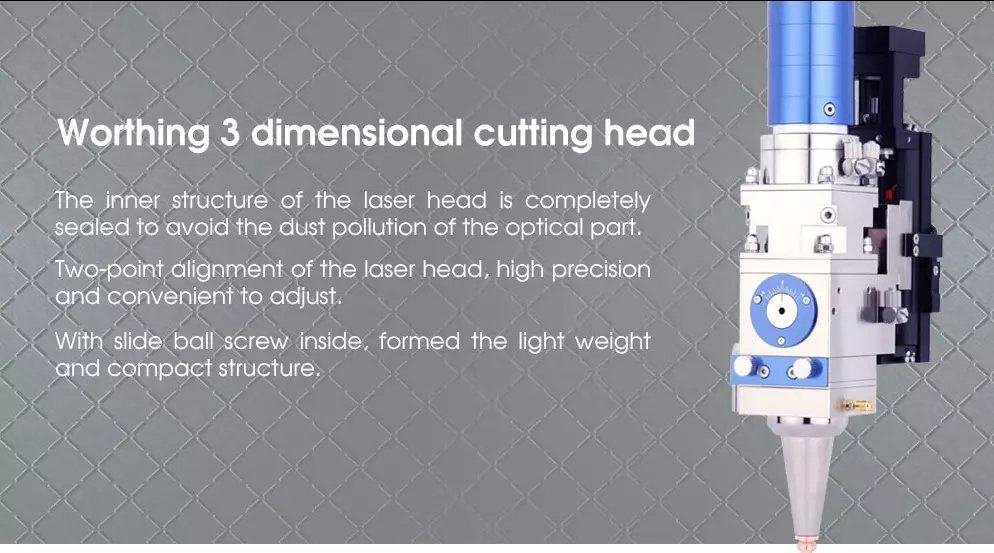

3. Three-dimensional laser cutting head: The international top-brand three-dimensional laser cutting head can be selected to ensure the laser beam is always in the focal position to ensure the cutting effect. The domestic laser cutting head with the same cutting capacity is standard, more economical, and affordable.

4. Auxiliary purge system: The system integrates a three-gas source structure with high-pressure air, nitrogen, and oxygen and is equipped with a high- and low-pressure conversion gas path.

5. Lubrication system: The three-dimensional robot laser cutting machine is equipped with a manual lubrication system to reduce the wear of moving parts and ensure the movement speed of the entire laser machine.

Robot Arm Laser Cutting Machine Application

Applicable materials:

They are mainly used for cutting various metal materials, such as carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel plate, pickled plate, aluminum zinc plate, and copper.

Applicable industries:

A fully automatic robotic fiber laser cutting machine is used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, machinery, precision components, ships, metallurgical equipment, elevators, household appliances, gifts and crafts, tool processing, decorations, advertising, metal external processing, and other manufacturing and processing industries.

DAG At Your Service

Pre-Sales Service

• Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (PLT, AI) or mail us your workpiece; we will cut it in the factory and make a video to show you the cutting process and results or send you a sample to check the cutting quality.

• Drive solution design:

According to the customer’s product processing requirements, we can design a unique solution for customers to support higher manufacturing efficiency and better processing quality.

• Customized machine design:

We can modify our machines according to the customer’s application to achieve customer convenience and high production efficiency.

After-Sales Service

• As a professional CNC laser manufacturer and supplier, DAG will provide English training videos and user manuals for fiber laser machine installation, operation, maintenance and troubleshooting, and provide you with English training videos and user manuals by email, phone, mobile phone, etc. when you encounter installation, operation or adjustment problems.

• You can come to our factory for training. We will provide professional guidance and direct face-to-face practical training. We have assembly equipment, various tools and testing equipment here. Training time: 3~5 days (recommended).

• Our engineers will visit your local site for on-site guidance and training services. We must assist with visa processing and prepay travel and accommodation expenses before deployment and during service.

Warranty

• Three-year warranty for the whole machine, 18-month warranty for the laser, 12-month warranty for the chiller, and no warranty for the lens/mirror/nozzle.

• Long-term lifetime maintenance: The after-sales department will provide 24/7 English online support.

• We are responsible for providing free accessories during the warranty period, except for artificial damage.

• After the warranty period, the buyer is only responsible for the actual repair costs.

Frequently Asked Questions

If you need a free quote and detailed solution, please answer the following questions and let us know by email so that we can recommend the most suitable machine and quote you an affordable price.

• Do you need to cut metal plates, tubes, or both?

• If you need to cut tubes, what is the length, diameter, and maximum thickness of your tubes?

• What is the maximum working area required for cutting metal plates?

• How much do you plan to budget for customizing the machine?

• What will the processed material be used for (applicant)

• Which seaport is closest to you?

• Do you have experience with laser cutting?

• What is your online chat method, such as Skype, WhatsApp or WeChat

• Are you an end user or a dealer?

If you have any questions, please contact us; our sales managers are online 24/7 to receive your questions or requests and provide solutions within 12 hours!

Reviews

There are no reviews yet.