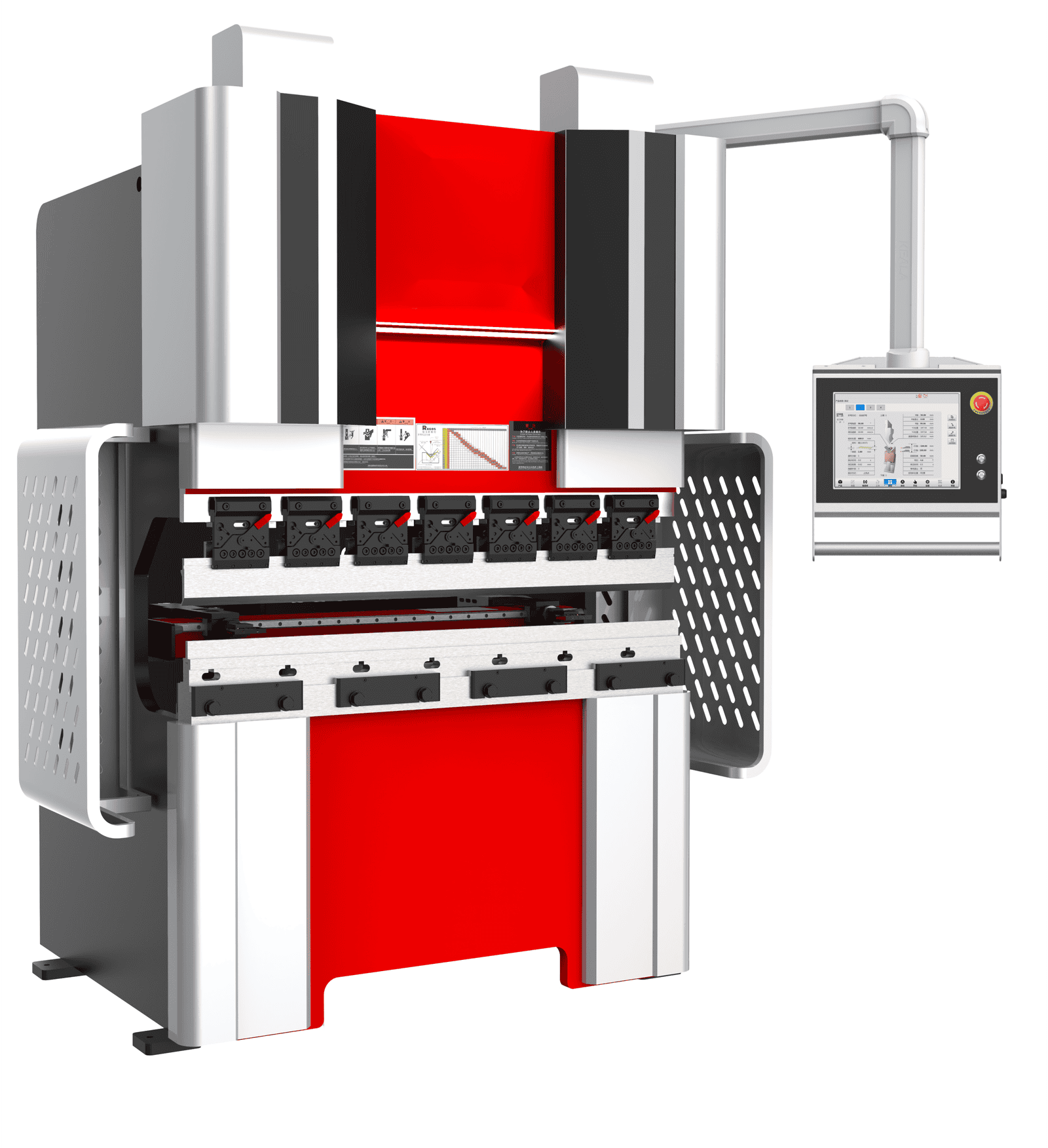

What is a pure electric press brake?

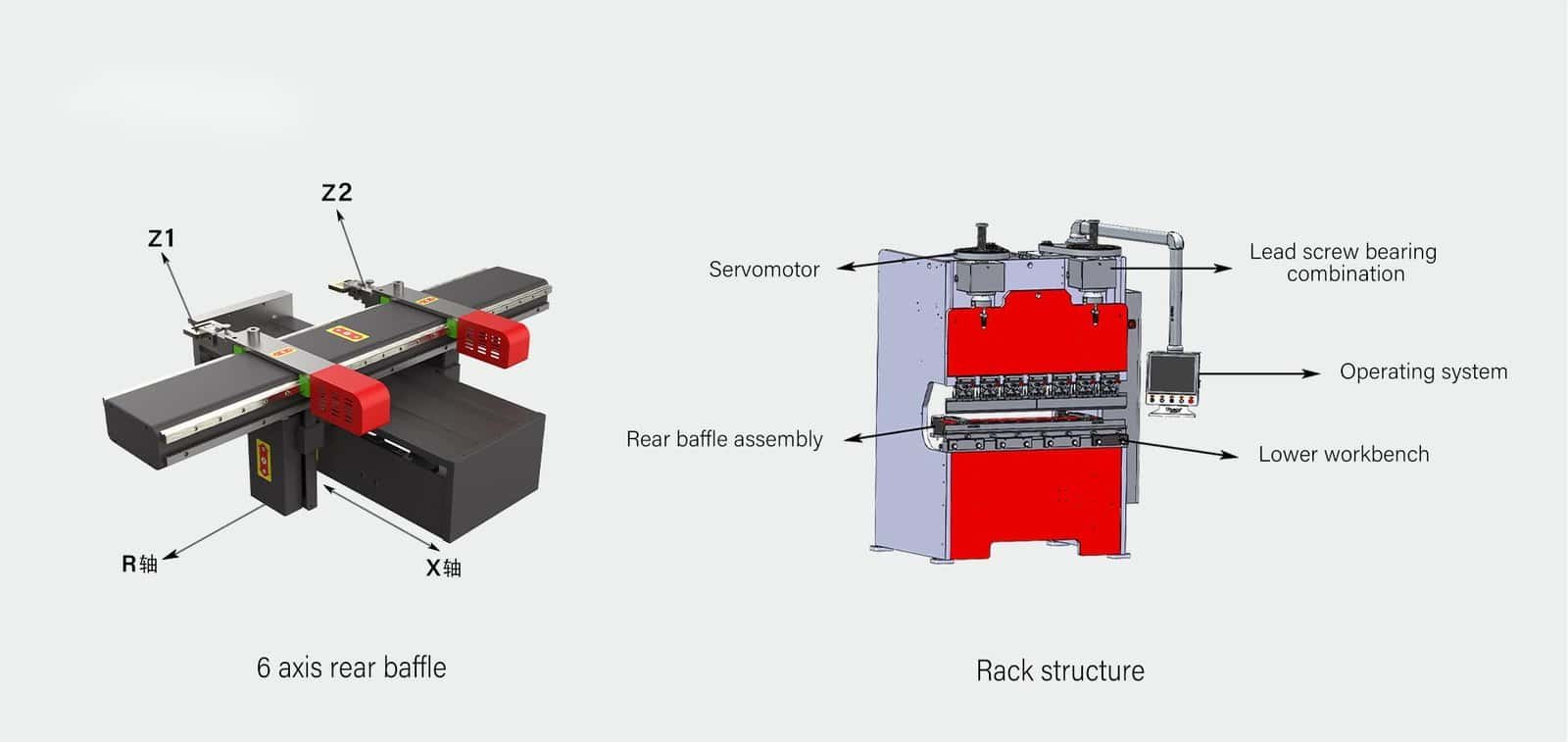

A pure electric press brake is a machine tool that bends sheet metal into various shapes and angles to meet market demand. Unlike traditional bending machines, it relies on a servo motor for power transmission. The servo motor drives a large-lead ball screw to squeeze and bend the sheet through the pressure of the upper workbench.

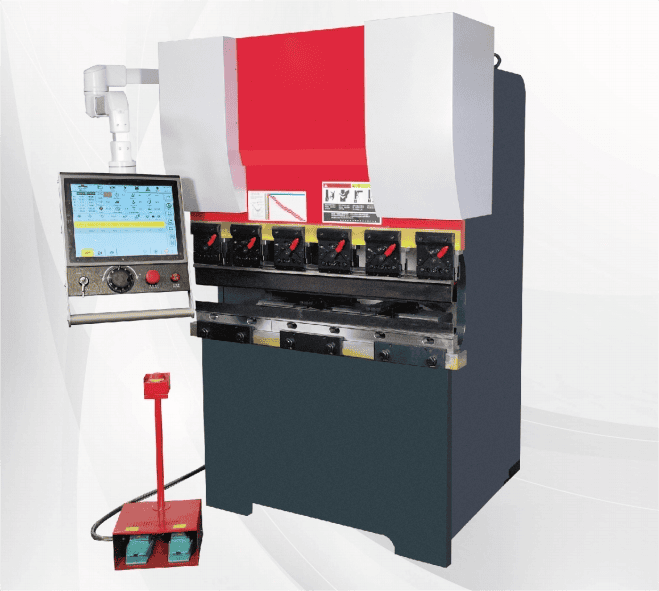

ES Series Pure Electric CNC Press Brake

Machine Parameters

| Name | Unit | ES-4013 |

| Processing Capacity | KN | 400 |

| Bending Length | MM | 1300 |

| Table Height | MM | 850 |

| Throat Depth | MM | 300 |

| Opening Height | MM | 400 |

| Bending Stroke | MM | 130 |

| Number Of Machine Tool Axes | AXIS | 6 |

| Y1, Y2 Descent Speed | MM | 0-150 |

| Y1,Y2 Pressurization Speed | MM/S | 0.2-50 |

| Y1,Y2 Rising Speed | MM/S | 0-150 |

| X-axis Stroke | MM | 495 |

| X-axis Speed | MM/S | 600 |

| R-axis Stroke | MM | 150 |

| R-axis Speed | MM/S | 200 |

| Z1,Z2 Stroke | MM | 790 |

| Z1,Z2 Speed | MM/S | 600 |

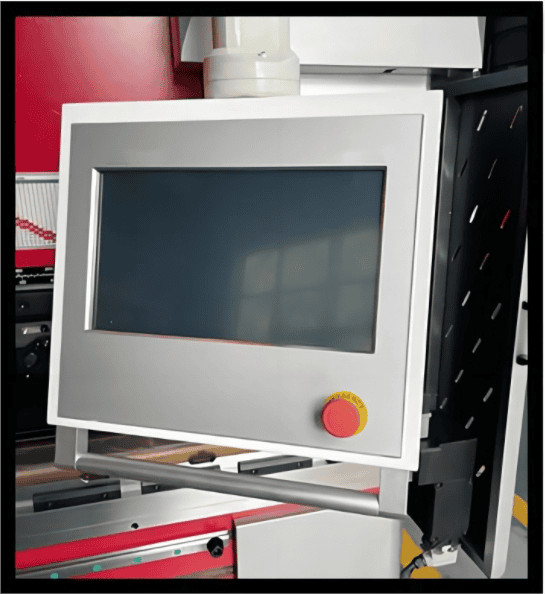

| Operating System | ES6 | |

| Dimension | MM | 1585*1440*2200 |

| Total Weight | KG | 3500 |

Machine Parameters

| Name | Unit | ES-6020 |

| Processing Capacity | KN | 600 |

| Bending Length | MM | 2000 |

| Table Height | MM | 850 |

| Throat Depth | MM | 300 |

| Opening Height | MM | 400 |

| Bending Stroke | MM | 130 |

| Number Of Machine Tool Axes | AXIS | 6 |

| Y1, Y2 Descent Speed | MM | 0-150 |

| Y1,Y2 Pressurization Speed | MM/S | 0.2-50 |

| Y1,Y2 Rising Speed | MM/S | 0-150 |

| X-axis Stroke | MM | 495 |

| X-axis Speed | MM/S | 600 |

| R-axis Stroke | MM | 150 |

| R-axis Speed | MM/S | 200 |

| Z1,Z2 Stroke | MM | 1450 |

| Z1,Z2 Speed | MM/S | 600 |

| Operating System | ES6 | |

| Dimension | MM | 2285*1440*2250 |

| Total Weight | KG | 4500 |

Machine Details

-detail.png)

EG Series Pure Electric CNC Press Brake

Machine Parameters

| Model | EG-8025 | EG-6020 | EG-4015 | EG-3512 | EG-2508 |

| Nominal pressure | 80ton | 60ton | 40ton | 35ton | 25ton |

| Length of workbench | 2500mm | 2000mm | 1500mm | 1200mm | 800mm |

| Height of workbench | 940mm | 900mm | 900mm | 900mm | 700mm |

| Height of the opening | 470mm | 420mm | 420mm | 420mm | 420mm |

| Throat depth | 410mm | 410mm | 410mm | 200mm | 200mm |

| Travel distance of the pressureboard | 150mm | 150mm | 150mm | 150mm | 150mm |

| Back and forth movement ange ofthe rear-fixina device | 500mm | 500mm | 500mm | 500mm | 400mm |

| Rising/descending speed of thepressure board | 240mm/s | 240mm/s | 260mm/s | 260mm/s | 260mm/s |

| Pressing speed of the pressureboard | 10-30mm/s | 10-30mm/s | 10-30mm/s | 10-30mm/s | 10-30mm/s |

| Back-and-forth moving speed ofthe rear fixing device | 500mm/s | 500mm/s | 500mm/s | 500mm/s | 500mm/s |

| Number of machine axis | 6 axis | 6 axis | 6 axis | 6 axis | 4 axis |

| Total power capacity | 45KVA | 37KVA | 26KVA | 23KVA | 19KVA |

| Main motor power | 13*2KW | 11*2KW | 7.5*2KW | 5.5*2KW | 7.5KW |

| Weight of equipment | 8300kg | 5500kg | 3900kg | 3000kg | 2000kg |

| Machine dimension(L/W/H) | 3240*1400*2665mm | 2580*1480*2600mm | 2140*1475*2600mm | 1840*1375*2400mm | 1450*1320*2400mm |

| Total power | 30.3Kw | 22.8Kw | 15.8Kw | 14.0Kw | 8.3Kw |

Machine Details

Control System Optional

Delem DA,CYBBELEC CybTouch

10.1-15″LCD TFT true colour display

Deflection compensation control

Profile-53TL off-ine programming software

Can be adapted to 4-8 axis control, manual

automatic simulation bendingprocedures

Can realize the function of graphic scanning code, 2D/3D graphic display

Fast Clamp

The standard equipped fast clamp will help you replace the top punch in a very short time. Convenient and time-saving. Fast

intermediate loading and unloading function to improve work efficiency.

Mechanical Crowning

The motorized crowning system will adjust the parallelism and straightness automatically.

Schneider Electrical

Our press brake adopts Schneider Electric components. The high

quality electric parts can make the machine perform well even if the electricity is unstable, and customers can quickly get the replacement anywhere in the world.

Video Demonstration

Five Advantages of Fully Servo Pure Electric Press Brake

Energy saving

One of the advantages of pure electric servo drive technology is that the input power of the motor is proportional to the load power. The energy consumption is large during bending, the power is small when the slider is unloaded and upward, and there is no power when the slider stops.

Even if the slider of the hydraulic servo bending machine is not working, the main motor and hydraulic pump will continue to run and consume electricity.

Taking the monthly electricity consumption as a reference, the monthly electricity consumption of the pure electric servo model is only 30%-50% of that of the electro-hydraulic servo model.

Environmental protection

The pure electric servo bending machine does not use hydraulic oil, and replacing hydraulic oil or components is not troublesome. There is no hydraulic oil leakage during the replacement process and daily system, and no waste oil treatment and pollution.

High production efficiency

Compared with electro-hydraulic models, the full servo motor ball screw CNC bending machine has a screw transmission, no switch valve delay, and higher efficiency, and compared with the same type of electro-hydraulic model, the efficiency will be increased by 50%-80%.

High bending accuracy

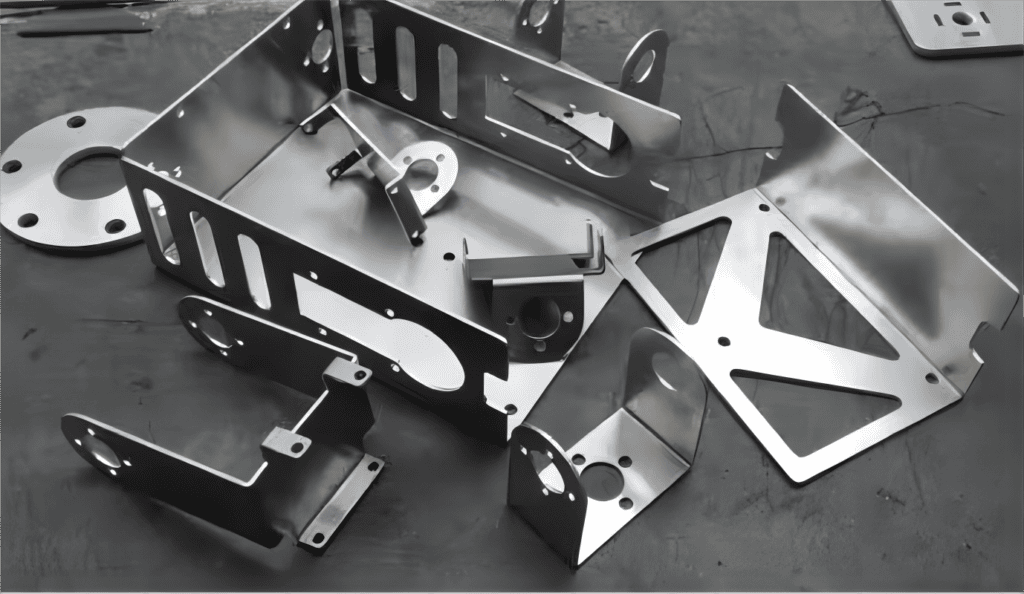

The bending speed of the pure electric servo bending machine is adjustable. It can set a more appropriate bending speed for different thicknesses, materials, and lengths to improve bending accuracy and maintain high productivity. The main drive of the servo bending machine drives the screw through a servo motor, which has higher transmission accuracy. Measuring the bending angles of plates of various specifications can ensure the bending angle error is within ±0.5°. Compared with the same electro-hydraulic machine, the bending accuracy can be improved by 20%-50%.

Low maintenance and use cost

The transmission system of the pure electric servo bending machine is simple. It requires no maintenance and only regular lubrication.

The hydraulic oil of the hydraulic bending machine needs to be replaced regularly. Pumps, valves, and seals are prone to failure and damage, and the hydraulic system is easily contaminated, which is not easy to detect and troubleshoot. Once the hydraulic system is infected, it is difficult to clean, which will cause environmental pollution.

How do you choose between electro-hydraulic and pure electric press brakes?

When choosing a bending machine, you may face a significant decision: should you choose an electro-hydraulic bending machine (electro-hydraulic servo CNC bending machine) or a pure electric bending machine (pure electric servo CNC bending machine)? Let’s see which bending machine can best meet your needs.

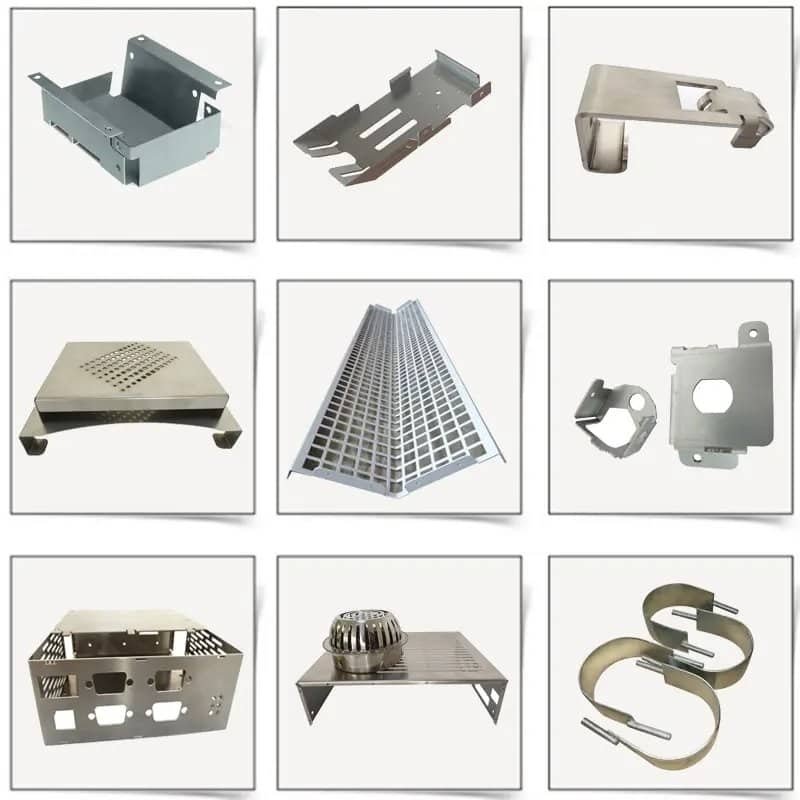

Work efficiency and precision

1. Electro-hydraulic bending machine: DAG’s electro-hydraulic servo bending machine is like an experienced craftsman who handles thick plates and large-scale production. It has high stability and repeatability and can easily handle high-load processing tasks. If your production tasks are tedious and heavy, it is our best partner.

2. Pure electric bending machine: DAG’s pure electric bending machine is more like an agile dancer, precise and fast, especially suitable for processing thin plates and precision workpieces. The intelligent operating system of the pure electric bending machine performs well in high-precision and small-batch production. If you have strict requirements for speed and precision, the pure electric bending machine will be your most loyal “dance partner”.

Energy saving and environmental protection

1. Electro-hydraulic bending machine: Although the hydraulic system requires regular maintenance and replacement of hydraulic oil, DAG’s electro-hydraulic bending machine still performs well under high tonnage and large bending capacity. Although the maintenance cost is a bit “luxurious”, its strong performance ensures that your production line is always as good as new.

2. Pure electric bending machine: DAG’s electric bending machine is an energy-saving expert. It is not only environmentally friendly but also efficient. Its high energy efficiency and low maintenance requirements make long-term operating costs more attractive. If you want to be at the forefront of environmental protection and energy saving, this equipment is your “green hero”.

Operation and maintenance

1. Electro-hydraulic bending machine: DAG’s electro-hydraulic bending machine is simple and intuitive to operate, but the maintenance of the hydraulic system cannot be ignored. Please rest assured that we provide full-service support to ensure equipment “stays young forever”.

2. Pure electric bending machine: DAG’s pure electric bending machine has an advanced CNC system that is easy to operate and requires low maintenance. Like a high-tech intelligent assistant, our equipment will allow you to quickly “get it done” without complicated operations.

Cost

1. Electro-hydraulic bending machine: The initial investment of a DAG electro-hydraulic bending machine is relatively affordable, making it suitable for “big projects” with limited budgets. Although the long-term operating costs are slightly higher, its high performance will make your investment worthwhile.

2. Pure electric bending machine: The initial investment of a DAG pure electric bending machine is slightly higher, but its ultra-high energy efficiency and low maintenance requirements make the long-term operating costs more attractive. It not only saves energy but also allows you to “shine” financially.

Whether you choose DAG’s electro-hydraulic bending machine or pure electric bending machine, we are confident that we can provide the most suitable solution. Electro-hydraulic bending machines are suitable for “showing off their skills,” while pure electric bending machines are better in precision, energy savings, and environmental protection. Let DAG’s bending machine become a capable assistant on your production line and help your company “fold” a new world!

-500x500.png)

-500x500.png)

Reviews

There are no reviews yet.