Is a portable handheld laser welding machine worth buying?

Portable handheld laser welding machines are worth buying. In contemporary manufacturing, welding technology constitutes a crucial means of joining diverse materials. Laser welding technology has gained wide popularity along with advancing science and technology due to its efficient and precise traits. As a component of laser welding technology, industrial and individual users have favoured the handheld laser welding machine for its portability and flexibility.

The portable handheld laser welding machine possesses the following advantages:

High Flexibility

The portable handheld laser welding machine is relatively small, occupies a limited area, and is easy to operate and manoeuvre. The space of the workbench does not constrain it and can meet the welding requirements of multiple angles and directions. It is particularly suitable for positions and workpiece parts that cannot be welded automatically and for welding operations in confined spaces.

Simple Operation

The equipment is straightforward to operate. Without professional welding and programming knowledge, it features drag-and-drop operation programming. The operator only requires one hour of training to complete flawless welding.

Good Stability

The front end of the welding gun is typically equipped with a copper nozzle. The copper nozzle can contact the workpiece during the welding process, reduce the weight of the welding gun, enhance the welding stability, and complete conventional and shaped welds well. The weld is aesthetically pleasing, without welding scars, and no polishing is required, with solid firmness.

High Precision

After focusing, the diameter of the laser beam is small, exerting little influence on the surrounding materials. This can reduce the material damage that is prone to occur in the traditional welding process and minimize the subsequent processing of fragile materials, thereby improving production efficiency.

Fast Welding Speed

The product’s welding speed is 5-10 times that of argon arc welding, which can save labour costs. In the mass production of products, the speed and efficiency advantages of the handheld laser welding machine are particularly prominent. The machine can be adapted to the automated production line to achieve fully automated operation, ensuring product quality and shortening the production cycle.

Environmental Protection and Safety

The laser welding machine welds quickly and deeply, with a narrow weld seam and less post-processing capacity, making it more environmentally friendly. Due to non-contact welding, it is highly safe as long as the operation avoids hand contact with the laser beam.

Wide Range of Applications

It is suitable for welding various metal materials such as stainless steel, carbon steel, aluminium alloy, copper, and galvanized sheet.

Technical parameter

| Model | DG-LW1018 |

| Laser Power | 1000W/1500W/2000W/3000W optional |

| Laser Source | Max Raycus IPG BWT optional |

| Welding Head | Qilin Raytools optional |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cabinet size | 845*490*550mm |

| Cooling System | Water Cooling |

| Voltage | 220V/3-Phase/50Hz |

| Function extension | Can be upgraded to 3-in-1 functions (welding, cleaning, cutting) according to customer requirements |

| Welding thickness(complete penetration) | ||||

| Material | 1 KW | 1.5 KW | 2 KW | 3 KW |

| Stainless steel | 2.5mm | 3.5mm | 4.5mm | 6mm |

| Carbon steel | 2mm | 3mm | 4mm | 5.5mm |

| Aluminum | 2mm | 3mm | 4mm | 5.5mm |

| Brass | 1mm | 2mm | 3mm | 4.5mm |

| Galvanized sheet | 2.5mm | 3.5mm | 4.5mm | 6mm |

Product details

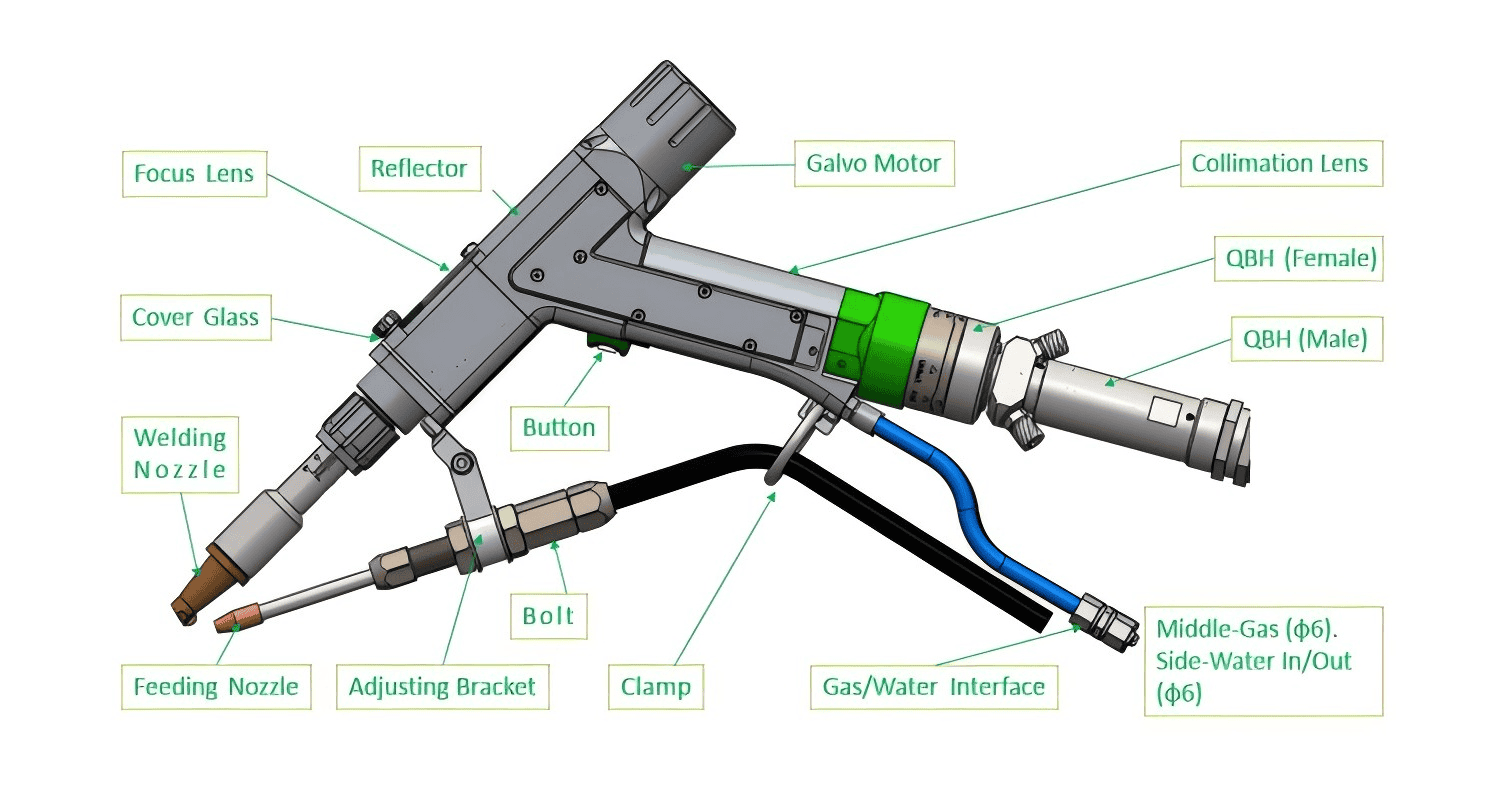

Laser Welding Head

1. Nozzle: Customers can modify the corresponding nozzle based on diverse welding procedures and twist the copper nozzle to regulate the focal length. The focus position has an adjustable range of ± 15 mm.

2. Wire feeding device: The wire feed structure with light bending enables effortless adjustment of the wire feed angle position.

3. Gas pipe interfaces: Protective gas inlet.

4. Lead signal cables: They are connected to a copper nozzle. During welding, contact with the ground wire of the iron plate generates a circuit and functions as safety protection.

5. Protect the lens mounting port: The protective lens has a water-cooled structure, enabling it to last longer. It would be best to wipe the dust off the protective lens with an alcohol-free cotton swab daily.

6. Circulating water channel: The cold water circulation structure cools the reflector and the gun body.

7. Gun handle: Aluminum processing, light and comfortable to hold. After modifying the head’s structure, the trigger button’s position can be utilized for both left and right hands.

8. QBH protective cover: It is connected to the laser end. During installation, pay attention to cleaning to prevent dust from entering the gun body.

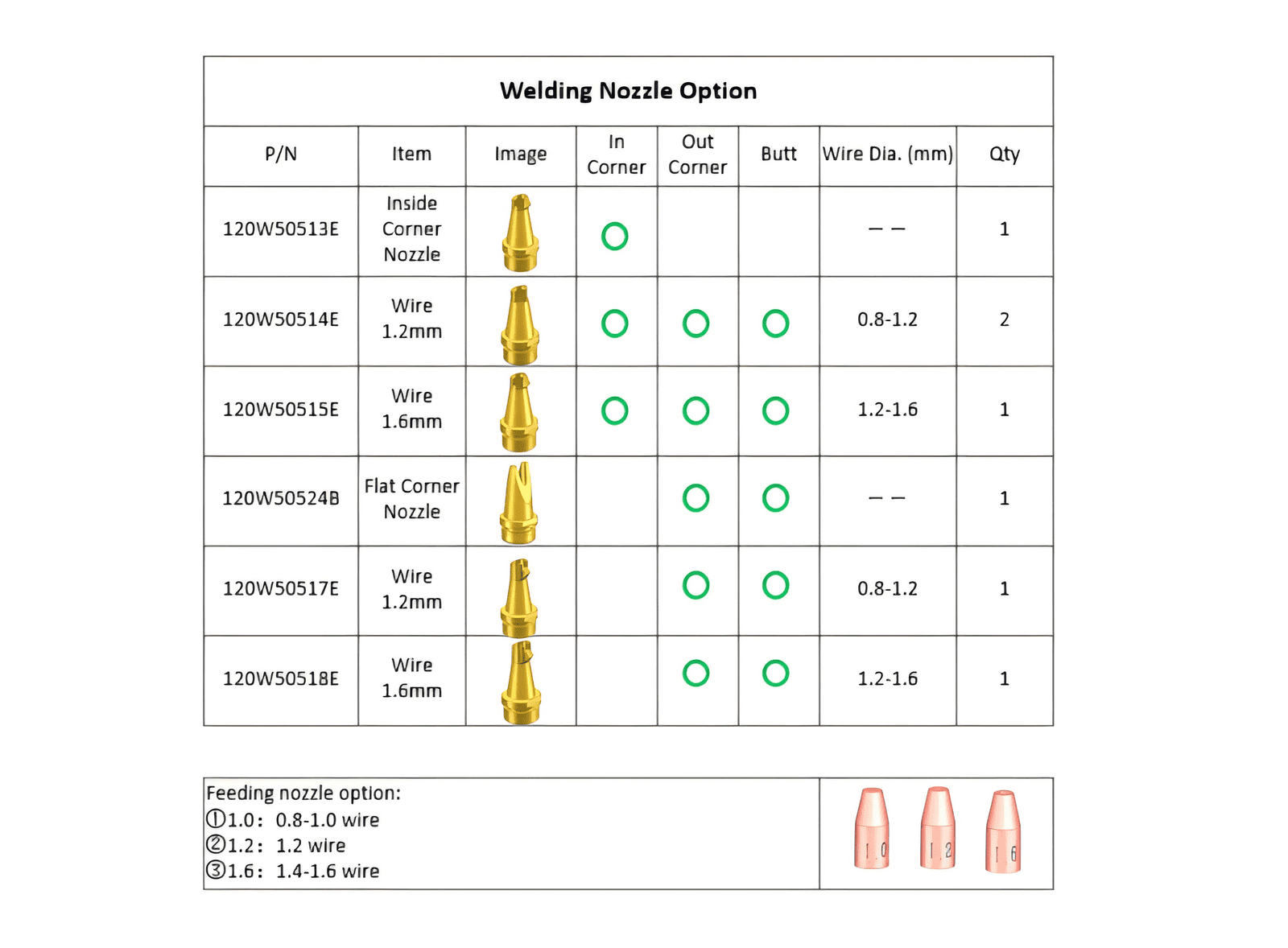

Welding Nozzle Option

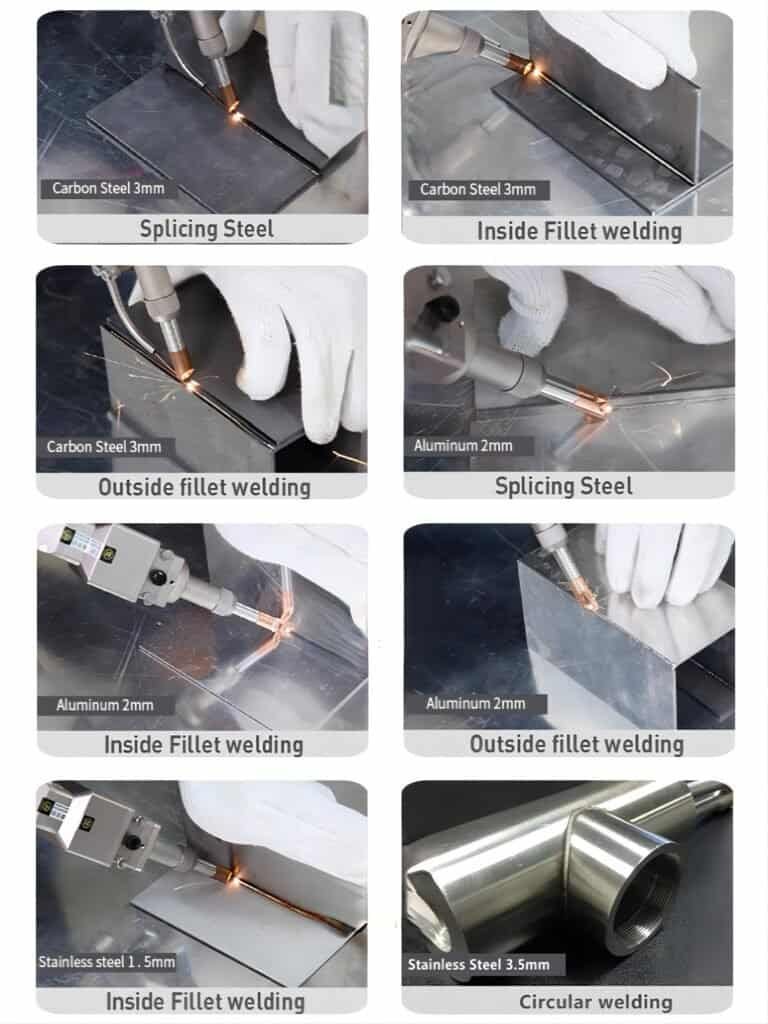

Welding illustration

How do you select a portable handheld laser welding machine that meets your requirements?

Choosing the suitable laser welding machine for your needs requires carefully considering many factors, from identifying specific needs to evaluating equipment performance, ease of operation and safety, and finally, combined with after-sales service.

Understand your specific needs

You must identify your needs before choosing a handheld laser welding machine. Includes:

Welding materials: Different laser welding machines are suitable for different materials, such as stainless steel, aluminium alloy, and carbon steel. Knowing the type and thickness of the material you need to weld is the basis for selecting the equipment.

Welding requirements: According to the specific requirements of the product, consider the quality of the weld, welding speed, precision and other aspects of the needs.

Working environment: Consider the workplace space, ventilation conditions, power supply, and other factors that will affect the choice of welding machine.

Consider laser power

Laser power is one of the core parameters of a handheld laser weld, which directly affects the effect and efficiency of welding. The higher the power, the faster the welding speed and the greater the welding depth. Choose the suitable power welding machine according to your actual needs, such as:

Sheet welding: It is recommended to choose a 500W-1000W laser welding machine.

Thick plate welding: Choosing more than a 1000W laser welding machine is recommended.

Pay attention to device stability and reliability

The handheld laser welding machine is to be used in different working environments, and the stability and reliability of the equipment are crucial. Choosing brands and manufacturers with good reputations and after-sales service can ensure the stability of the equipment in use, which can be repaired and provide technical support when a failure occurs.

Evaluate the ease of operation

The ease of operation of the handheld lasehandheldg machine directly affects the work efficiency and the operator’s comfort. Choosing a welding machine with an ergonomic design, moderate weight and simple operation can improve work efficiency and reduce operator fatigue.

Check security performance

Laser welding machines produce intense laser radiation during the working process, so choosing equipment with suitable safety protection measures is essential. F is necessary, such as being equipped with laser protective glasses, setting an emergency stop button, etc., to ensure the operator’s safety.

Understand after-sales service and technical support

Good after-sales service and technical support are essential guarantees to ensure the long-term stability of equipment operation. Choosing a manufacturer that provides comprehensive after-sales service and technical training can help reduce the failure rate and improve production efficiency while using your equipment.

The easiest and most direct way to buy

Please send your workpiece to us; we will process it according to your product processing requirements in the factory, make videos to show you the welding process and results, or send samples to you to check the welding quality. We then provide uniquely designed solutions to support higher manufacturing efficiency and better processing quality, saving you time and money!

Multiple models (optional)

| Model | DG-LW1023 |

| Laser type | Fiber Laser Source |

| Laser power | 1000W 2000W |

| Function | Handheld Metal Welding |

| Cooling System | Air Cooling |

| Laser source | Raycus/Max/JPT |

| Processing material | Metal Stainless Steel Carbon Steel |

| Welding mode | Handheld Laser Welding Head |

| Advantage | Easy Operate |

| After-sales Service Provided | Online Support |

| Model | DG-LW1016 |

| Laser Power | 2000W |

| Laser Source | BWT |

| Welding Head | Qilin |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cabinet size | 980*420*712mm |

| Cooling System | Water Cooling |

| Voltage | 220V/380V/50Hz |

| Model | DG-LW1015 | ||

| Laser Power | 1000W | 1500W | 2000W |

| Output fiber length | 10M | 10M | 10M |

| Welding thickness | 0.3mm-3mm | 0.3mm-4mm | 0.3mm-5.5mm |

| Voltage | 220V ±10V | 220V ±10V | 220V ±10V |

| Indicator light | Red Light | Red Light | Red Light |

| Cooling method | Wind cooling | Wind cooling | Wind cooling |

| Max pressure | 10bar | 10bar | 10bar |

| Total Power | 4Kw | 6Kw | 8Kw |

| Working model | Continuous/modulation | ||

| Working environment | Flat, no vibration and shock | ||

| Working humidity | <70% | <70% | <70% |

| Operating temperature | -10-45 ℃ | -10-45 ℃ | -10-45 ℃ |

| Model | DG-LW1017 |

| Laser power | 1000/1500/2000W |

| Working area | unlimited |

| Spot adjustment range | 0~5mm |

| Use wavelength | 1060nm-1080nm |

| Laser input interface | QBH |

| Collimator | D20/F50mm |

| Focusing lens | D20/F120mm |

| Protective glass | D20×2mm |

| Welding shielding gas | 8-25L/min |

| Weight | 150Kg |

Service & Commitment

After-Sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality Control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM Service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms Of Payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document Support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.