3 Nm³/h Nitrogen Generation Systems for Laser Welding

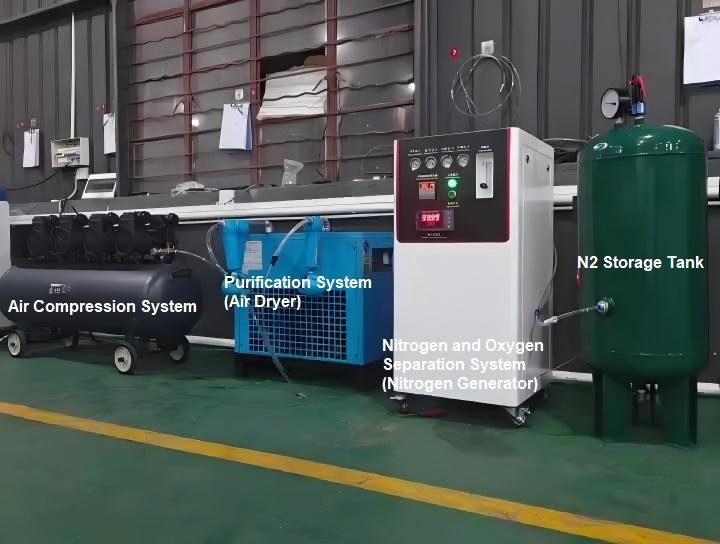

This 3 Nm³/h nitrogen generator is designed to provide high-purity nitrogen to support 3-4 laser welding machines simultaneously, ensuring optimal performance and efficient operation for a variety of applications.

Product Description

1. Dual-Tower PSA Technology: Utilizes pressure swing adsorption (PSA) with carbon molecular sieves for efficient nitrogen production. One tower absorbs oxygen while the other regenerates, ensuring a continuous supply of nitrogen.

2. Real-Time Monitoring: Provides operators with precise pressure and operating data to maintain optimal performance.

3. Compact Design: Small footprint, easily integrated into laser cutting or welding setups.

4. Energy Efficiency: Low power consumption (25W) reduces operating costs.

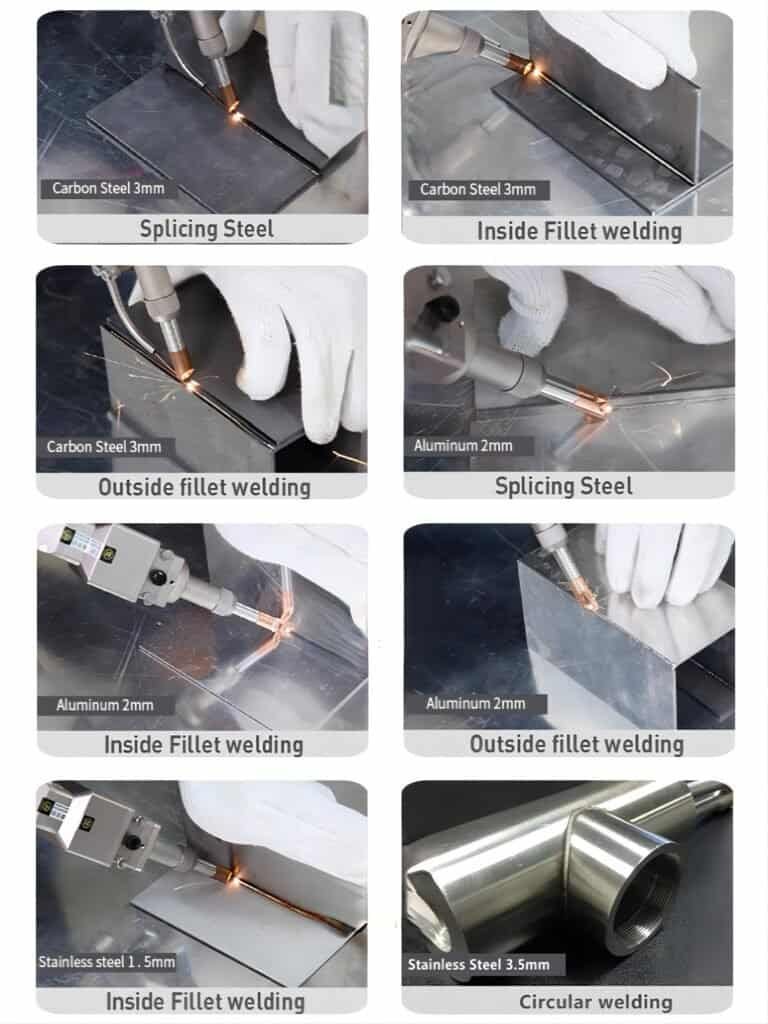

5. Applications: Laser welding: Creates a protective nitrogen atmosphere to prevent oxidation and improve weld quality.

6. Industries: Automotive, aerospace, metal fabrication, and electronics manufacturing.

Equipment Specifications

| Equipment type | DAG-03 |

| Nitrogen flow rate | 3NM³/h |

| Nitrogen purity | 95%-99.999% |

| Intake pressure | 0.6-0.8Mpa |

| Nitrogen pressure | 0.5-0.8Mpa |

| Air nitrogen ratio | 5.87:1 |

| Power | 60W |

| Supply voltage | AC100-250V |

| frequency | 50~60Hz |

| Rated intake | 1m³ /min |

| Equipment weight | 139.5 kg |

| Equipment size (L*W*H) | 650 * 700 * 1300 mm |

5 Nm³/h Nitrogen Generation Systems for Laser Welding

This 5 Nm³/h nitrogen generator is designed to provide high-purity nitrogen to support 5-6 laser welding machines simultaneously, ensuring optimal performance and efficient operation for a variety of applications.

Product Description

1. PSA Technology: Nitrogen is separated from compressed air using pressure swing adsorption (PSA). This process ensures efficient nitrogen production, high reliability, and low operating costs.

2. Nitrogen Flow Rate: 5 Nm³/h (standard flow rate) is ideal for 2-6 laser welding machines, depending on the specific requirements of each machine.

3. Nitrogen Purity: Typically provides 99.9% to 99.999% pure nitrogen, ensuring the laser welding process is oxygen- and moisture-free, preventing oxidation and improving operational precision.

4. Adjustable Pressure: Provides adjustable nitrogen output pressure (typically 0.6 MPa or lower), suitable for a variety of laser welding processes.

5. Energy Efficiency: Typically consumes low power (approximately 25-50W), making it an energy-efficient solution for industries requiring a continuous nitrogen supply.

6. Compact Design: These systems feature a compact design that allows for easy integration into a workshop or industrial environment without taking up excessive space.

7. Applications: Laser welding: Provides a stable protective atmosphere during the welding process, ensuring a strong, oxidation-free weld.

8. Industries: Automotive, aerospace, metal manufacturing, electronics, etc.

Equipment Specifications

| Equipment type | DAG-05 |

| Nitrogen flow rate | 5NM³/h |

| Nitrogen purity | 95%-99.999% |

| Intake pressure | 0.6-0.8Mpa |

| Nitrogen pressure | 0.5-0.8Mpa |

| Air nitrogen ratio | 5.9:1 |

| Power | 60W |

| Supply voltage | AC100-250V |

| frequency | 50~60Hz |

| Rated intake | 1m³ /min |

| Equipment weight | 190 kg |

| Equipment size (L*W*H) | 650* 700 * 1300 mm |

Advantages of Nitrogen Generation System

Multi-Machine Support

Ideal for companies with multiple laser cutting or welding machines that require a continuous nitrogen supply.

Cost-Effective

On-site nitrogen generation reduces reliance on external gas suppliers and eliminates the storage and transportation costs of bottled nitrogen.

Compact Design

These systems feature a compact design that easily integrates into a workshop or industrial environment without taking up excessive space.

Continuous Supply

Provides a continuous and stable supply of nitrogen, eliminating the need for bottled gas or liquid nitrogen, improving operational efficiency and reducing gas costs.

Low Maintenance

Maintenance costs are minimal; the carbon molecular sieve is typically replaced every 5-8 years, depending on usage and air quality.

Continuous Operation

Ensures a continuous nitrogen supply even during long production cycles, without the need for interruptions or frequent refills.

Laser Application Advantages

Improves weld quality: In laser welding, nitrogen protects the weld area from oxidation, resulting in stronger, higher-quality welds.

Typical Applications

Frequently Asked Questions

Why is nitrogen used in laser applications?

Nitrogen is commonly used in laser systems to prevent oxidation, improve weld quality, and extend the life of laser equipment. It acts as a shielding gas, replacing oxygen, which can cause oxidation or contamination during processes like laser welding.

How does a nitrogen generator work?

A nitrogen generator uses pressure swing adsorption (PSA) technology to separate nitrogen from compressed air. It absorbs oxygen and other impurities, allowing only nitrogen to pass through, producing a steady stream of nitrogen with the required purity and pressure.

What are the air quality requirements for a nitrogen generator?

To ensure optimal performance from a nitrogen generator, the air source must be clean, dry, and oil-free. An air dryer and oil filter are recommended in the compressed air system to meet these requirements.

What is the purity of the nitrogen produced by a nitrogen generator?

Typical purity for laser applications ranges from 95-99.9%, depending on the model and configuration. Nitrogen purity must meet the specific requirements of the laser system to prevent oxidation and ensure high-quality performance.

What is the maximum pressure a nitrogen generator can provide?

The maximum output pressure of a nitrogen generator is typically between 5 and 8 bar (0.5 and 0.8 MPa). However, be sure to check the specifications of your specific nitrogen generator model to ensure it meets the pressure requirements of your laser equipment.

Can a nitrogen generator be used for multiple laser systems?

Yes, a nitrogen generator can be used to supply nitrogen to multiple laser systems, provided the total required flow rate does not exceed the generator’s output capacity.

What are some common maintenance tasks for a nitrogen generator?

Filter Replacement: Regularly replace the air and nitrogen filters to ensure high-quality nitrogen production. Cleaning: Clean the exterior of the equipment to avoid dust and debris accumulation. Never allow cleaning agents or water to enter the system. Inspection: Inspect the system’s pressure gauges, valves, and connections for leaks or signs of wear. Dryer Maintenance: Maintain the air dryer system to ensure the incoming air remains dry and moisture-free.

How can I tell if the nitrogen purity is insufficient?

If the nitrogen purity falls below the required level (typically below 95% for laser applications), the system may display an alarm or fault indicator. It is recommended to regularly monitor nitrogen purity with a nitrogen analyzer to ensure consistent quality.

What is the lifespan of a nitrogen generator?

If properly maintained, a nitrogen generator can last up to 10-15 years. Regular maintenance, such as changing filters, cleaning, and monitoring system components, helps extend its lifespan.

What should I do if my nitrogen generator stops working?

If the generator stops working, check for the following common issues: Air supply problems (low pressure or moisture contamination). Electrical problems (power failure or switch failure). Clogged filters or valve failure. For more complex issues, refer to the troubleshooting section of the user manual or contact customer service.

Can the generator operate in extreme temperatures?

Nitrogen generators are generally designed to operate within a moderate temperature range. Extremely high or low temperatures can affect performance. Ensure the operating environment is within the manufacturer’s recommended temperature range.

How can I safely handle nitrogen?

While nitrogen is inert and non-toxic, it can displace oxygen in confined spaces, causing oxygen depletion. When using nitrogen in confined spaces, ensure adequate ventilation and avoid exposure to high nitrogen concentrations.

What is the power consumption of a nitrogen generator?

Power consumption depends on the specific model and its configuration. Typically, it ranges from 1-5 kW. Please review the product specifications for exact power requirements.

Service & Commitment

After-Sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality Control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM Service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms Of Payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document Support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.