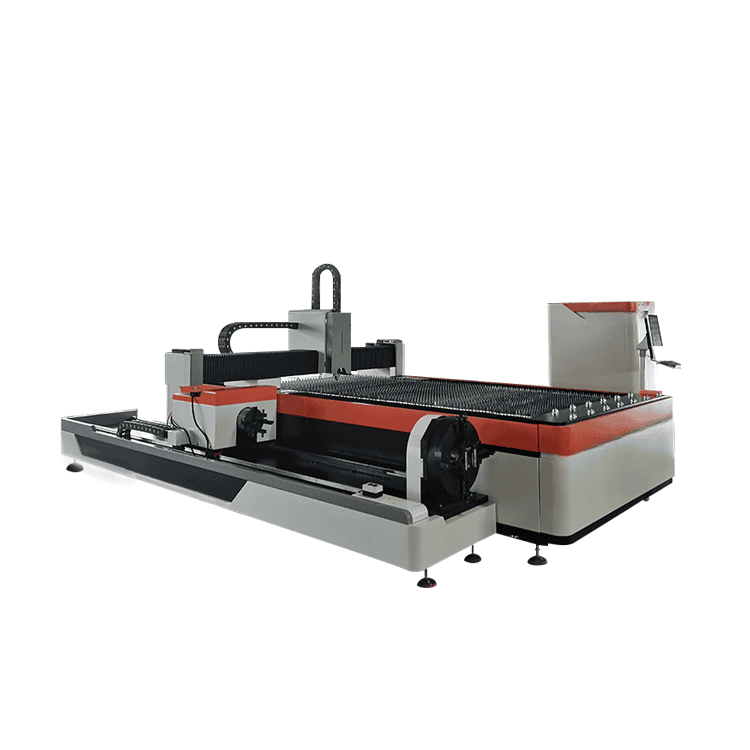

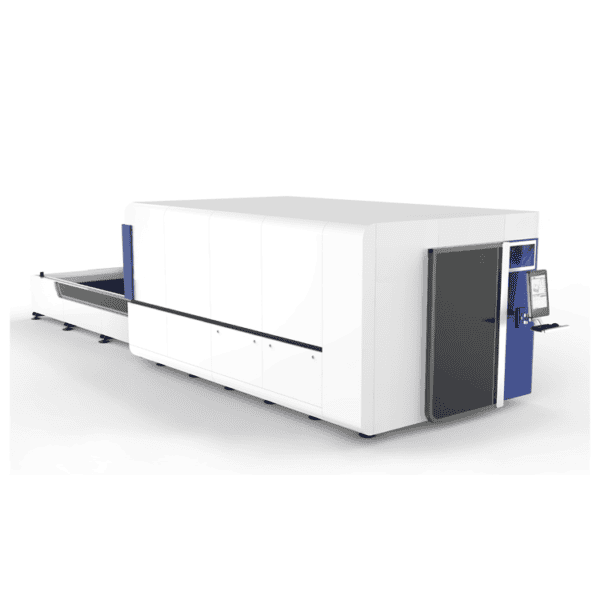

Metal Sheet & Tube Laser Cutting Machine Features and Advantages

1. The fiber laser source uses a Raycus 1000-8000W laser (optional: IPG/nLight /MAX), which is highly precise and stable. The service life of critical components can reach 100,000 hours.

2. The advanced CNC control system can directly read .ai, .plt, .dxf, .lxd and ug codes, has an automatic layout optimization function, and is easy to operate.

3. Raytools’ laser cutting head, with an automatic height adjustment function, maintains a constant focal length and stable cutting quality.

4. The imported Japanese Yaskawa servo motor and driver are used. They are exact, fast, have ample torque, and have stable and durable performance, ensuring high-speed operation of the whole machine.

The metal plate and tube fiber laser metal cutting machine can cut most plates, metal plates, metal tubes, and metal pipes. It significantly saves the cost of purchasing two machines, saves more than 50% of workshop space, and doubles production efficiency.

Product Parameter

| Laser source | Raycus/IPG/nLight /MAX (optional) | ||

| Laser Power | 1000w 1500w 2000w 4000w 6000w 8000w 12000w etc | ||

| Working Size | 3015 (optional 4020 6020 etc.) | Maximum Compound Velocity | 120m/min |

| X-Axis Travel | 3050mm | Peak Acceleration | 1.8G |

| Y-Axis Travel | 1520mm | X Y axis positioning accuracy | ±0.05mm |

| Z-Axis Travel | 130mm | X Y axis re-positioning accuracy | ±0.03mm |

| Machine Weight | 5000-9000kg | Maximum Load of Worktable | 1000kg |

| Outside Size | 4600*2300*1800mm | Power supply | 3phase /380V/50Hz |

| MULTI-FUNCTIONS | |||

| Shared-edge Cutting / Leapfrog Cutting / Breakpoint Return / Backspacing Function / Follow-up Control / Micro-connect Function /Scan Cutting / Automatic Edge Finding | |||

Metal Sheet & Tube Laser Cutting Machine Application Areas

Applicable materials: stainless steel, carbon steel, galvanized sheet, electrolytic sheet, brass, aluminum, steel, various alloy plates, rare metals and other materials. Applicable to cutting round tubes, square tubes, rectangular tubes, elliptical tubes and other special-shaped tubes.

Applicable industries: mechanical equipment, electrical equipment, hotel kitchen equipment, sports equipment, various pipes, water pipes, oil pipelines, elevator equipment, advertising signs, automobile decoration, sheet metal production, lighting hardware display equipment and other industries.

Details

Configuration List

| Parts | Optional Brand | Advantage |

| Control System | Cypcut / Au3tech /NCStudio | Domestic professional and widely used laser cutting system |

| Laser Source | Raycus/ Max /IPG/ N-light | Long life, efficient and safe |

| Laser Cutting Head | Raytools/Au3tech | Stable, long life, easy replacement of lossy parts, simple focus adjustment, optical components imported from Germany |

| Dust Removal Fan | Powerful dust removal fan | Bass, powerful, good dust extraction effect |

| Bed Working Size | 3000*1500mm/other | Suitable for most standard metal plates |

| Precision Gear Rack | YYC | High precision, high hardness and small error |

| Precision Linear Guide | HIWIN / THK | Original imported guide rail, high precision, stable, long life |

| Gear Reducer | MOTOREDUCER | 48 hours of ageing annealing to remove the effect of thermal stress on the machine tool |

| Servo Motor | Yaskawa/Panasonic/delta | The original imported servo system has high precision, stability, long life, and large domestic consumption. |

| Air Control | SMC | Imported high temperature and low-pressure proportional valve, Stable high and low-pressure switching, more stable cutting |

| Laser protective glasses | one pair | Standard |

| Protective lenses | five pieces | Standard |

| Toolbox | one set | Standard |

| Operation manual | one | Standard |

| Cutting software U disk | one | Standard |

| nozzle | 5-10 | Standard |

| Product certification | one | Standard |

Cutting Samples

DAG at Your Service

Pre-sales service

• Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (PLT, AI) or mail us your workpiece; we will cut it in the factory and make a video to show you the cutting process and results or send you a sample to check the cutting quality.

• Drive solution design:

According to the customer’s product processing requirements, we can design a unique solution for customers to support higher manufacturing efficiency and better processing quality.

• Customized machine design:

We can modify our machines according to the customer’s application to achieve customer convenience and high production efficiency.

After-sales service

• As a professional CNC laser manufacturer and supplier, DAG will provide English training videos and user manuals for fiber laser machine installation, operation, maintenance and troubleshooting, and provide you with English training videos and user manuals by email, phone, mobile phone, etc. when you encounter installation, operation or adjustment problems.

• You can come to our factory for training. We will provide professional guidance and direct face-to-face practical training. We have assembly equipment, various tools and testing equipment here. Training time: 3~5 days (recommended).

• Our engineers will visit your local site for on-site guidance and training services. We must assist with visa processing and prepay travel and accommodation expenses before deployment and during service.

Warranty

• Three-year warranty for the whole machine, 18-month warranty for the laser, 12-month warranty for the chiller, and no warranty for the lens/mirror/nozzle.

• Long-term lifetime maintenance: The after-sales department will provide 24/7 English online support.

• We are responsible for providing free accessories during the warranty period, except for artificial damage.

• After the warranty period, the buyer is only responsible for the actual repair costs.

Frequently Asked Questions

If you need a free quote and detailed solution, please answer the following questions and let us know by email so that we can recommend the most suitable machine and quote you an affordable price.

• Do you need to cut metal plates, tubes, or both?

• If you need to cut tubes, what is the length, diameter, and maximum thickness of your tubes?

• What is the maximum working area required for cutting metal plates?

• How much do you plan to budget for customizing the machine?

• What will the processed material be used for (applicant)

• Which seaport is closest to you?

• Do you have experience with laser cutting?

• What is your online chat method, such as Skype, WhatsApp or WeChat

• Are you an end user or a dealer?

Reviews

There are no reviews yet.