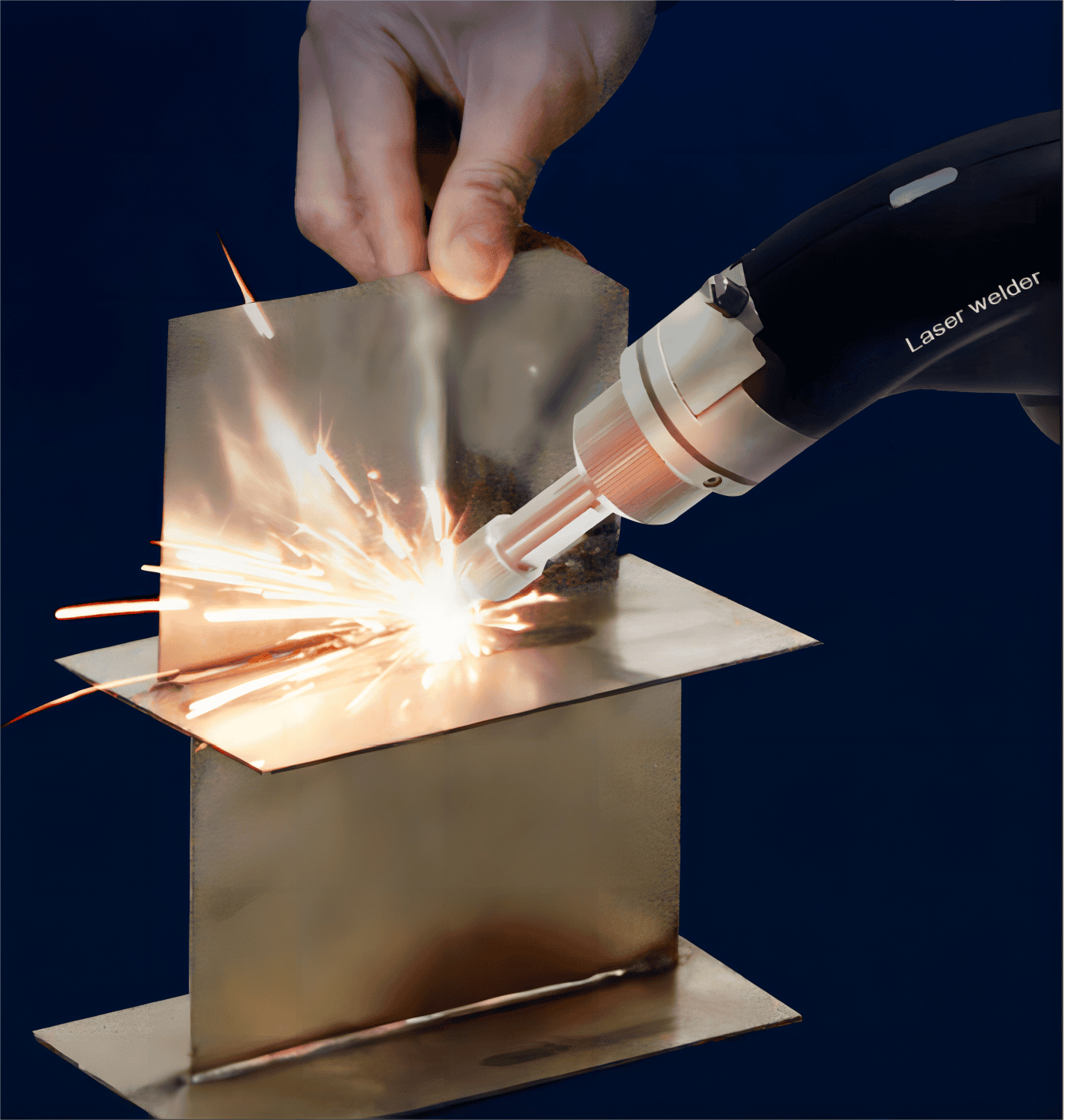

What is a lightweight handheld laser welding machine?

The lightweight handheld laser welder is portable, efficient, easy-to-operate laser welding equipment that utilizes fiber laser technology. It is designed to be lightweight, flexible, compact, and small, making it easy to carry and move and suitable for various complex work environments and confined spaces.

DG-HS series lightweight handheld laser welding machine, based on the company’s independent research and development of “small core diameter” laser technology, using a new double-circuit refrigerant direct cooling system and integrated structural design, is committed to providing customers with high efficiency, high penetration, high energy saving, high convenience experience. It can meet the welding needs of aluminum, stainless steel, carbon steel, galvanized sheet, brass and other metal materials (unique materials can be customized), widely used in hardware building materials, sheet metal processing, pipeline processing, household appliances, hardware kitchen and bathroom.

Ten advantages of products

☆ Beautiful and deep welding achieved with high penetration.

☆ Long service life cycle and more stable utilization.

☆ Fast performance for efficient working.

☆ Capable of working 7×24 hours without interruption.

☆ High and low-temperature resistant design, ensuring worry-free welding from -20℃ to 60℃.

☆ Intelligent operation for easy working.

☆ Human body-fitted design, comfortable and easy to hold.

☆ 8-protective design for safety and reassurance.

☆ High efficiency and energy saving, environmentally friendly and green.

☆ Eliminate dust hazards and safeguard workers’ health.

Product Specifications

| Item | Unit | DG-HS1023-3 | DG-HS1023-4 | DG-HS1023-5 |

| Rated input power supply | – | single phase 220V | single phase 220V | single phase 220V |

| Input power frequency | Hz | 50/60 | 50/60 | 50/60 |

| Rated input power | W | 3800 | 4200 | 5400 |

| Welding speed | cm/min | 20-80 | 20-80 | 20-80 |

| Cooling mode | – | Dual-Circuit Refrigerant Direct Cooling | Dual-Circuit Refrigerant Direct Cooling | Dual-Circuit Refrigerant Direct Cooling |

| Working temperature | ℃ | -20—60 | -20—60 | -20—60 |

| Storage temperature | ℃ | -30—70 | -30—70 | -30—70 |

| Working humidity | % | 0—90 | 0—90 | 0—90 |

| Product dimensions | mm | 673*480*310 | 673*505*310 | 673*505*310 |

| Product dimensions (excluding casters/pad and handle) | mm | 673*432*310 | 673*457*310 | 673*457*310 |

| Product weight | Kg | 43 | 43 | 45 |

| Applicable Wire Diameter | mm | 0.8/1/1.2/1.4/1.6 | 0.8/1/1.2/1.4/1.6 | 0.8/1/1.2/1.4/1.6 |

| Number of preset process packages | PCS | 24 | 30 | 40 |

| Number of customizable process packages | PCS | 20 | 20 | 20 |

| Output mode | – | Integrated armored cable+welding gun | Integrated armored cable+welding gun | Integrated armored cable+welding gun |

| Welding mode | – | Spot welding/continuous spot welding/pulse welding/continuous welding | Spot welding/continuous spot welding/pulse welding/continuous welding | Spot welding/continuous spot welding/pulse welding/continuous welding |

Product weldability performance

| PARAMETERS MATRIX FOR WELDING WITH WIRE FEED | |||||

| Aluminum | Stainless Steel | Galvanized Sheet | Carbon Steel | ||

| DG-HS1023-5 | single side | 5mm | 5mm | 5mm | 5mm |

| DG-HS1023-4 | single side | 4mm | 4mm | 4mm | 4mm |

| DG-HS1023-3 | single side | 3mm | 3mm | 3mm | 3mm |

| PARAMETERS MATRIX FOR SELF-FLUXING WELDING | |||||

| Aluminum | Stainless Steel | Galvanized Sheet | Carbon Steel | ||

| DG-HS1023-5 | single side | 5mm | 6mm | 6mm | 6mm |

| DG-HS1023-4 | single side | 4mm | 5mm | 5mm | 5mm |

| DG-HS1023-3 | single side | 3mm | 4mm | 4mm | 4mm |

✲✲✲ The above data are the maximum averaged full penetration obtained through multiple rounds of experiments

Product details

Laser Welding Head

Capable of 24 x 7 continuous welding, thanks to the refrigerant direct cooling system developed independently by DG and welding gun insulation material that can ensure long-term use without becoming hot or shut down.

Dual Circuit Refrigerant Direct Cooling Technology

The operating environment temperature of conventional water handheld welders is between 5 °C and 50 °C, while that of air-cooled handheld welders is between -10 °C and 35 °C. The refrigerant direct cooling system developed independently by DG ensures good environmental temperature adaptability, with an operating temperature ranging from -20 °C to 60°C.

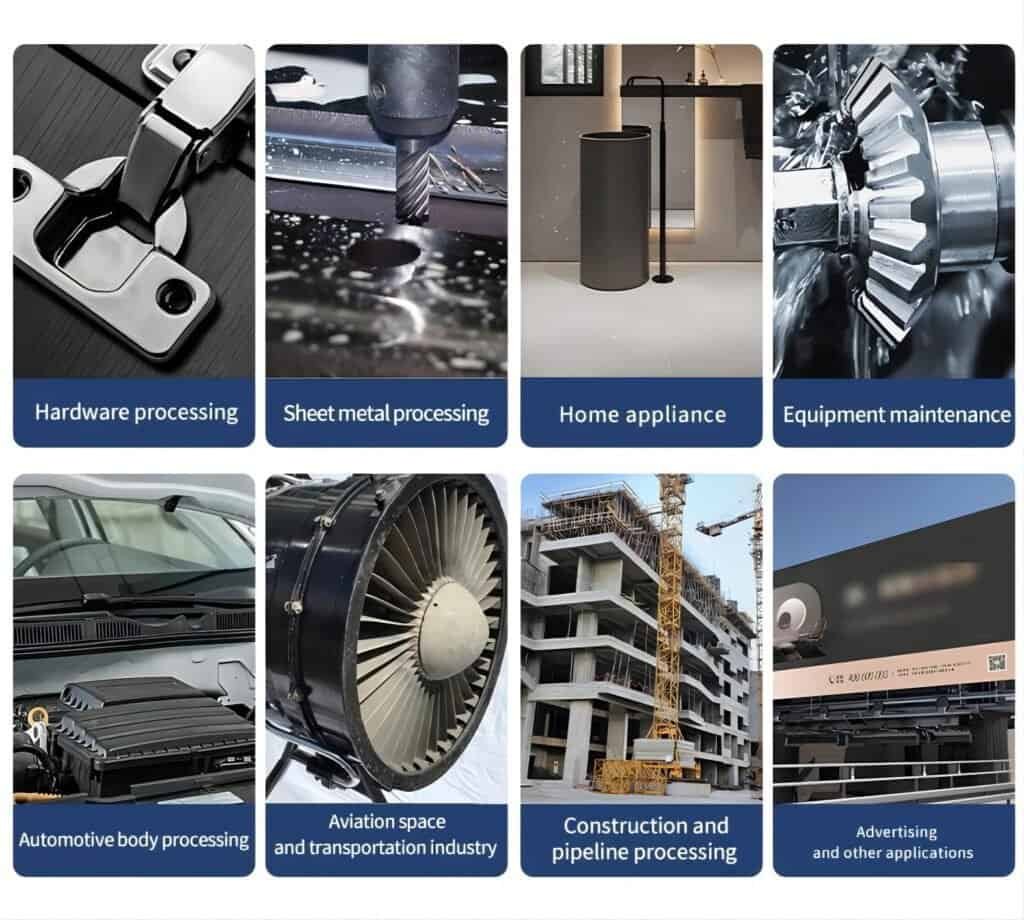

Product Application

Service & Commitment

After-Sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality Control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM Service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms Of Payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document Support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.