In which industries are pulse laser rust cleaners used?

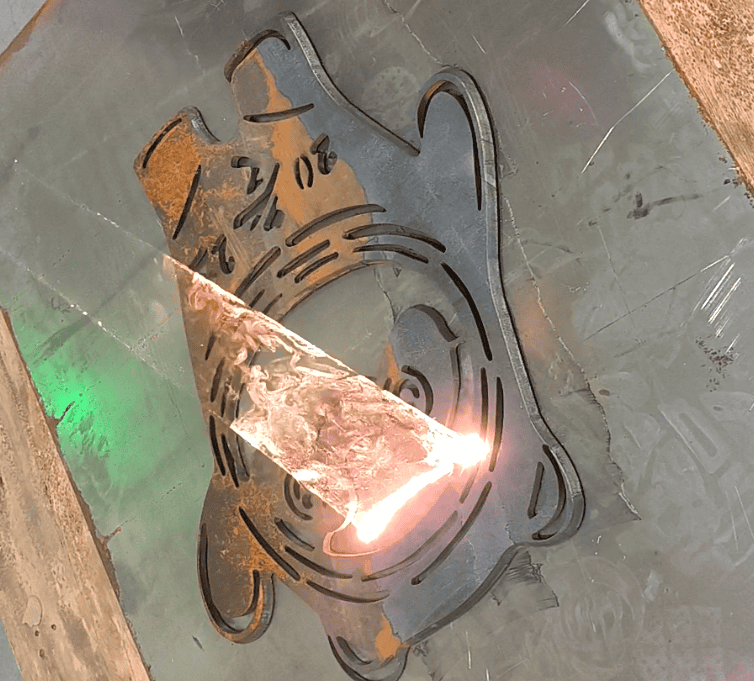

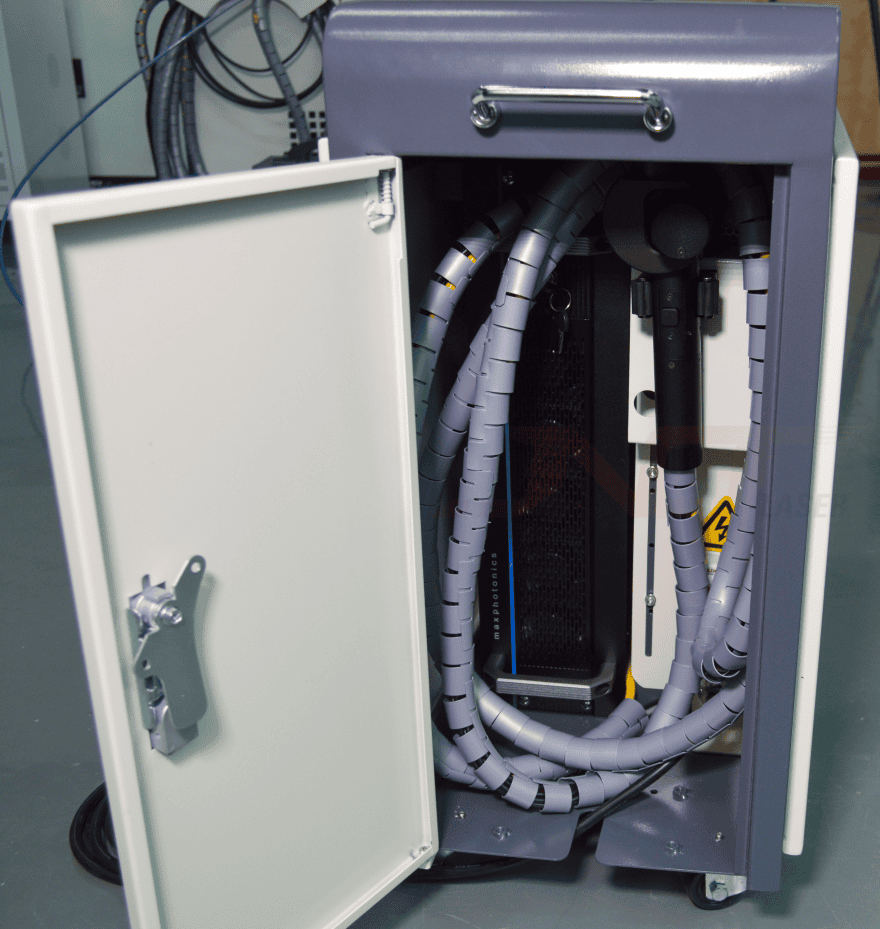

Pulse laser rust cleaners are equipment that uses laser technology to clean surfaces. They can instantly irradiate the object’s surface to be cleaned with a high-energy pulse laser beam and instantly evaporate or peel off dirt, oxide layers, coatings and other substances, thereby efficiently cleaning the object’s surface.

Pulse laser cleaning machines have the advantages of high cleaning efficiency, good cleaning quality, and no environmental pollution, so they have been widely used in many industries.

Automotive industry

Pulse laser rust cleaners have been widely used in the automotive manufacturing and maintenance industries. During automobile manufacturing, various parts will be contaminated by oil, oxide layers, and other substances. Pulse laser rust cleaners can quickly and efficiently clean these parts, improving production efficiency and product quality. In the automotive maintenance industry, pulse laser rust cleaners can clean engine parts, car body surfaces, etc., to help maintenance personnel perform maintenance work better.

Aerospace field

Pulse laser rust cleaners also have critical applications in the aerospace field. The aerospace field has stringent requirements for the cleaning of parts because any dirt or oxide layer may affect their performance and safety. Pulse laser rust cleaners can help the aerospace industry clean various parts to ensure that their surfaces are clean and pollution-free and improve flight safety.

Metal processing industry

Pulse laser rust cleaners can clean metal parts’ oxide layer, coating, etc., to improve metal products’ quality and surface finish.

In general, Pulse laser rust cleaners have critical applications in many industries. They can help companies improve production efficiency and product quality, reduce production costs, and achieve clean production that meets the requirements of modern industrial development. With the continuous development and improvement of laser technology, the application field of pulse laser cleaning machines will be further expanded, bringing more development opportunities to various industries.

Pulse Laser Rust Cleaner Parameters

| Model Number | DG-PC200 |

| Power Consumption | 1KW/1.2KW |

| Laser Power | 100W/200W |

| Cleaning Focal Length | 160mm/254mm |

| Cooling System | air cooling |

| Laser Wavelength | 1070nm |

| Current Regulation | 30–300A |

| Power regulation | 10–100% |

| Pulse Width | 10—500ms |

| Pulse Frequency | 1-4000KHZ |

| Maximum single pulse energy | 1.8mj |

| cleaning width | 110mm/175mm |

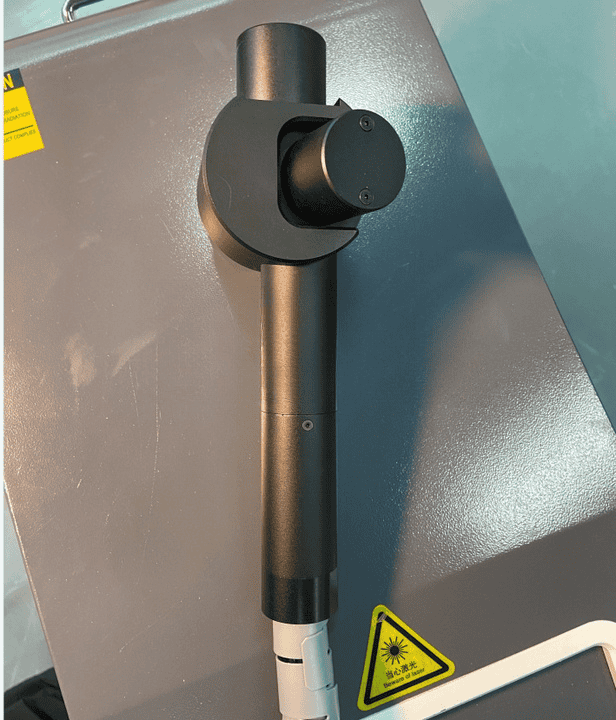

| Handheld length | 4m |

| Machine Voltage | AC220V±10% 50HZ/60HZ |

| Language | Standard Chinese, English, can be customized |

| Package size and weight | 760*320*680mm 50KG |

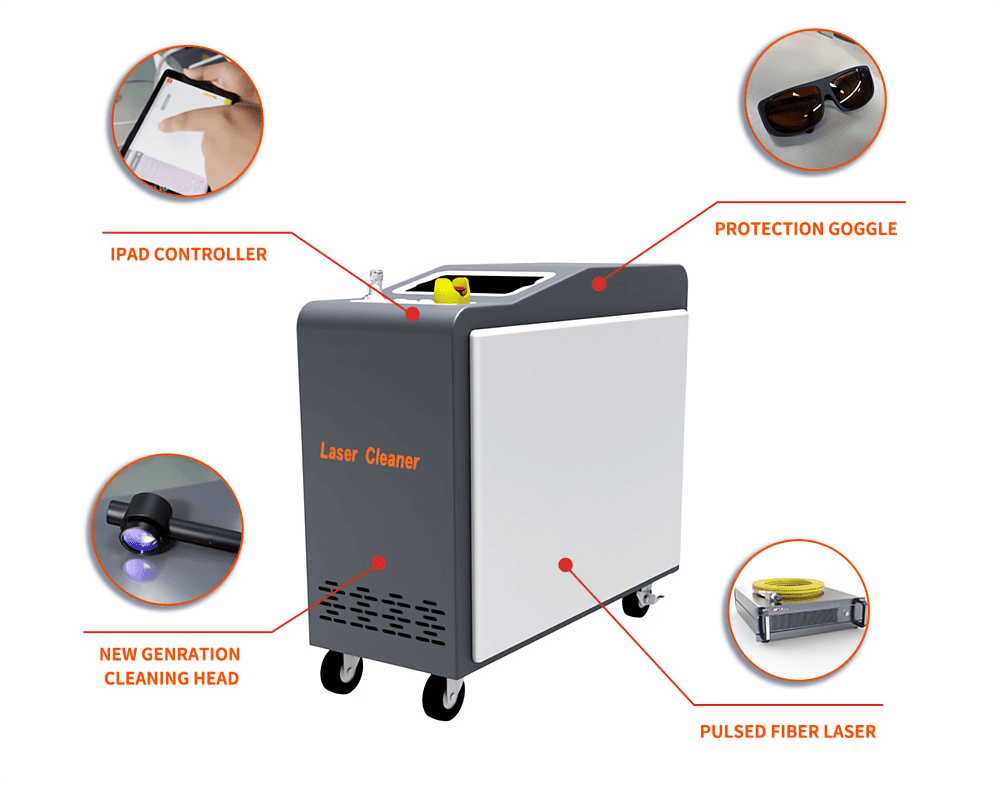

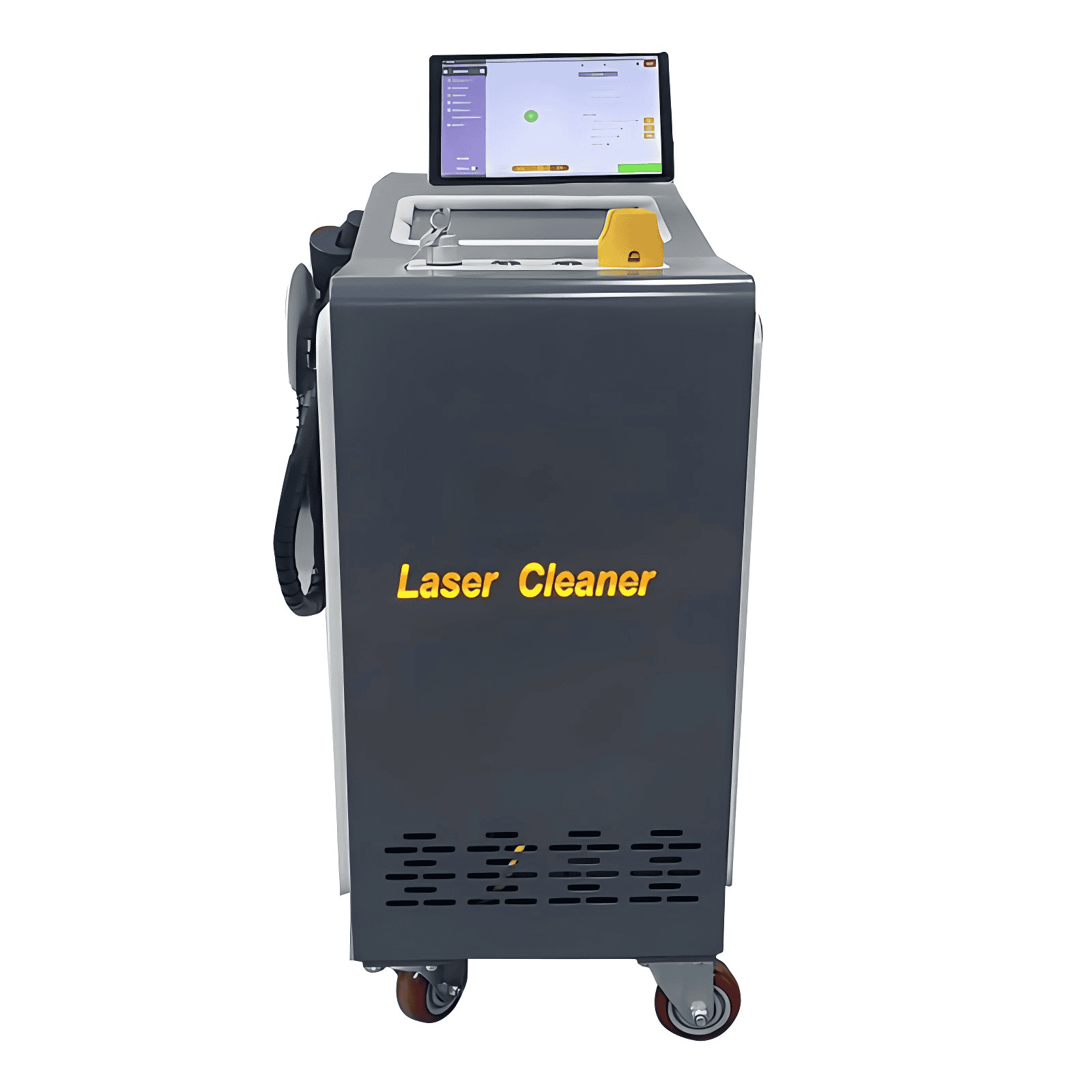

Machine features

1. Metal button switch, LOGO with light design

2. Customizable appearance design, small size, easy to move

3. IPAD controller, more convenient handheld operation

4. 8 cleaning modes, easy to operate, energy-saving and safe

5. Can adapt to various working environments, no noise, no pollution, no consumables, no contact

Advantages of pulse & continuous laser rust cleaner and how to choose

Pulse laser rust cleaner

Advantages

High peak power: It can provide extremely high peak power, making it more effective when processing hard-to-remove materials.

Fine control: The adjustability of pulse width and frequency allows the operator to optimize for different cleaning tasks and achieve satisfactory control.

Small heat-affected zone: Since the laser pulse has an extremely short action time, the heat-affected zone can be significantly reduced, which is suitable for cleaning heat-sensitive materials.

Disadvantages

Higher cost: Pulsed laser cleaning machines are generally more expensive to manufacture and maintain than continuous lasers.

Processing speed: Due to intermittent emission, its processing speed may be lower than that of continuous laser cleaning machines for large-area cleaning tasks.

Application scenarios

It is suitable for treating dirt that is difficult to clean, such as oxide layers, coatings, welding slag, etc. It is ideal for cleaning tasks with delicate parts or high surface quality requirements.

Continuous laser rust cleaner

Advantages

High efficiency: Continuous laser emission is suitable for large-area cleaning tasks and has a fast processing speed.

Low cost: Continuous laser cleaning machines have relatively low production and maintenance costs compared to pulsed lasers.

Easy to operate: Continuous laser equipment is generally easy to operate and integrate into automated production lines.

Disadvantages

Large heat-affected zone: Continuous laser output will produce a sizeable heat-affected zone and may not be suitable for cleaning heat-sensitive materials.

Low power density: Compared with pulsed lasers, its peak power is lower and may not perform well when removing specific types of stubborn contaminants.

Application scenarios

It is suitable for cleaning light dirt attached to the surface, such as paint, grease, dust, etc., and for cleaning large flat surfaces.

Selection suggestions

In general, continuous laser cleaners are suitable for cleaning large areas, while pulsed laser cleaners are suitable for cleaning dirt and delicate parts that are difficult to clean. The specific type of laser cleaner should be considered comprehensively based on factors such as the cleaning object, cleaning requirements, and budget.

Service and Commitment

After-sales

We provide 1-3 years warranty and lifelong maintenance for our products. During the warranty period, any functional defects (except for human or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge the workpiece fee based on the actual situation.

Quality Control

We have employed a skilled and rigorous quality inspection team during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to the engineering department.

We will provide customers with detailed machine pictures and test videos before delivery.

OEM Service

With our rich experience, we warmly welcome customization and OEM orders. All OEM services are free of charge. We can customize machine design, function, colour, and logo… for customers.

There is no minimum order quantity requirement. One unit can still enjoy wholesale price.

Privacy

Your personally identifiable information (such as your name, address, email address, bank information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions or requests for assistance will be responded to within 24 hours, even on holidays. If you have any urgent questions, please call us.

Payment Terms

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms include PayPal, Western Union, etc.

Document Support

Support all customs clearance documents: contract, packing list, commercial invoice, export declaration, etc.

Time to complete order

Machine production time is 7-10 days. Air freight time is 5-7 days, and sea freight is about 30 days. It depends on which shipping method you prefer.

Reviews

There are no reviews yet.