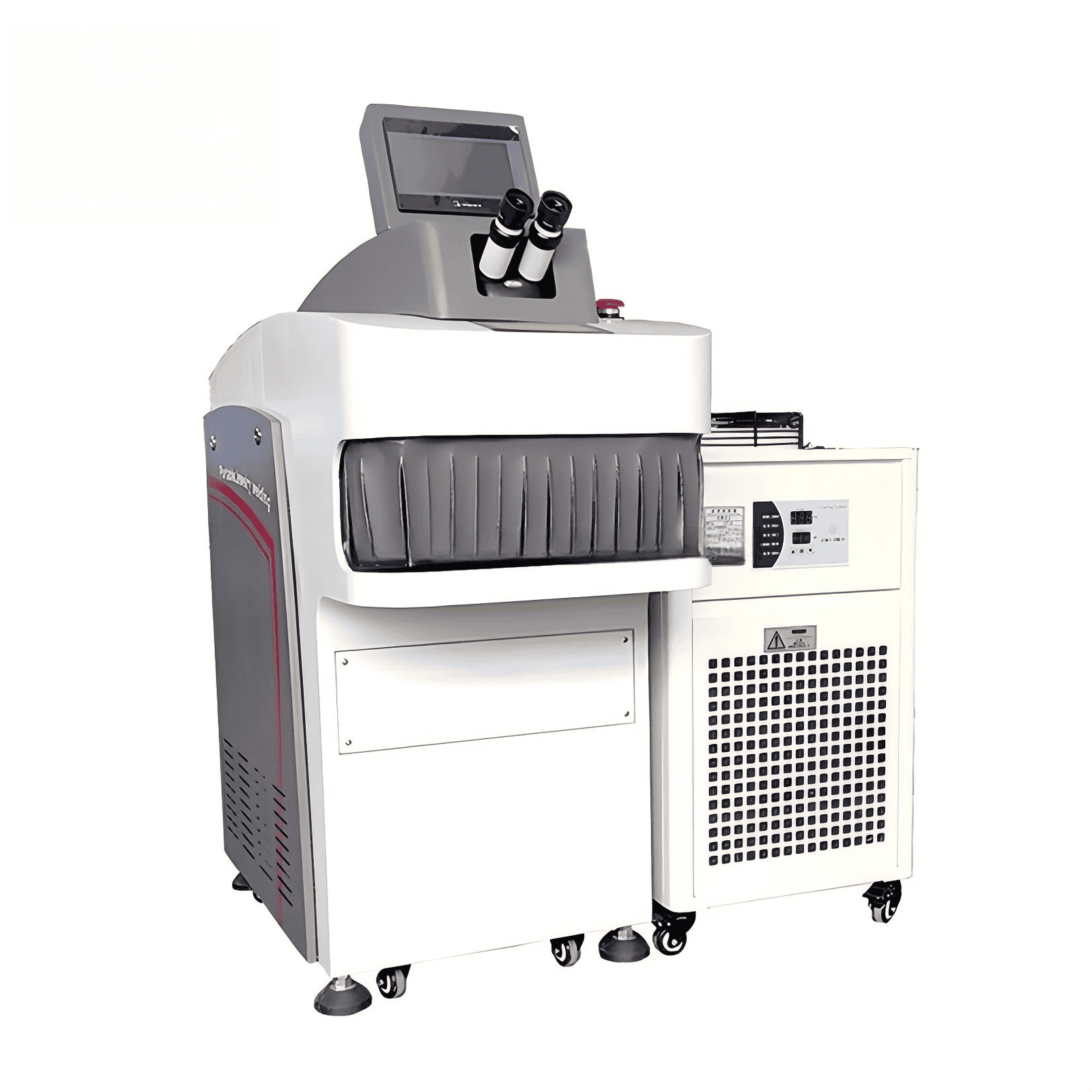

Are you looking for a jewellery laser welder? The core component of the DAG jewellery laser welder, the “laser focusing cavity”, uses a gold-plated reflective focusing cavity, which has a more stable performance and longer service life. The single pulse energy is 15% higher than that of ordinary power supplies and is more suitable for welding requirements of high-resistance materials such as gold and silver.

We can customize the machine according to your requirements (welding materials, power, cabinet appearance, etc.) to provide efficient and economical processing solutions. The DAG jewellery laser welder is worth your possession!

Advantages of laser welding machines in jewellery applications

Fine processing

The diameter of the laser beam can be as small as the micron level, enabling seamless welding on highly narrow gaps and small parts, perfectly adapting to the needs of small and exquisite jewellery.

Wide range of materials

Whether it is precious metals such as gold, platinum, and silver or acceptable repairs before and after gemstone inlay, laser welding can be done quickly to ensure the original colour and texture of the material.

Smooth weld

Due to the high energy concentration and rapid cooling characteristics of laser welding, there is almost no trace of the welding part, maintaining the smoothness and gloss of the jewellery surface.

Environmental protection and safety

Compared with traditional welding methods, laser welding produces less smoke and dust, reduces the emission of harmful substances, and is more in line with modern green manufacturing.

Product Parameters

| Laser Power | 100W/150W/200W(Optional) |

| Max Single Pulse Energy | 120J |

| Laser Wavelength | 1064nm |

| Pulse Frequency | ≤100Hz |

| Repeating Precision | ±0.1mm |

| Pulse width | ≤20ms |

| Spot Adjusting Range | 0.1-3.0mm |

| Power Consumption | 6KW |

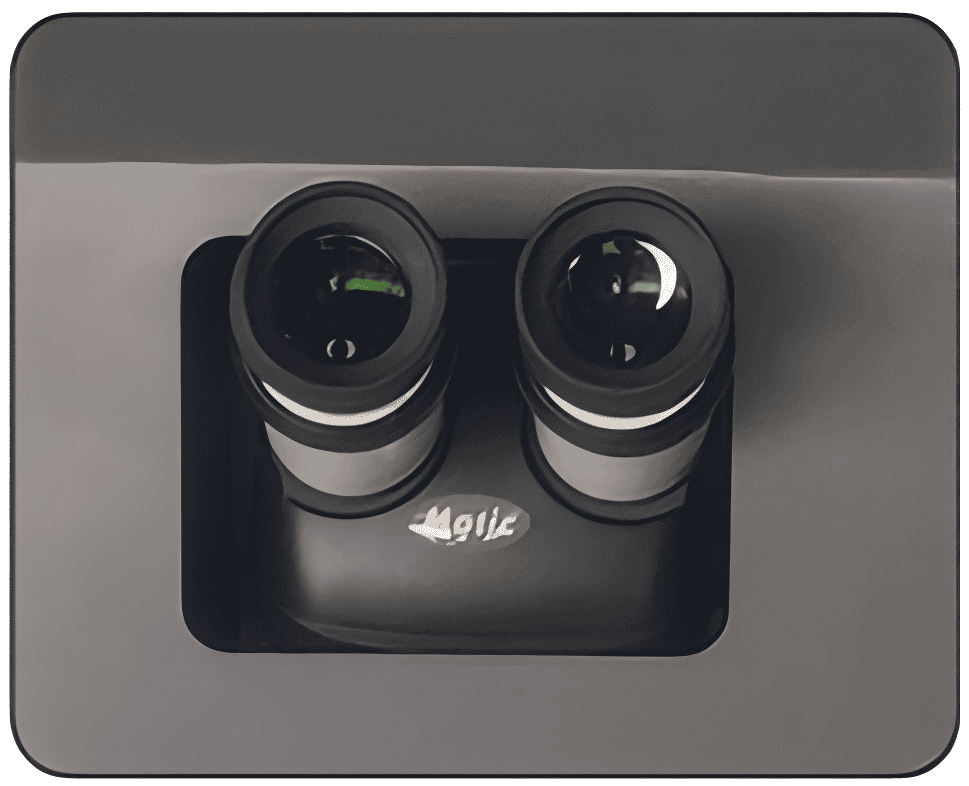

| Viewing System | Microscope |

| Voltage | 220V/50HZ |

| Cooling | Water Cooling |

| Cabinet Size | 1000*580*1280mm |

| Cabinet Style Color | Custom Or Standard |

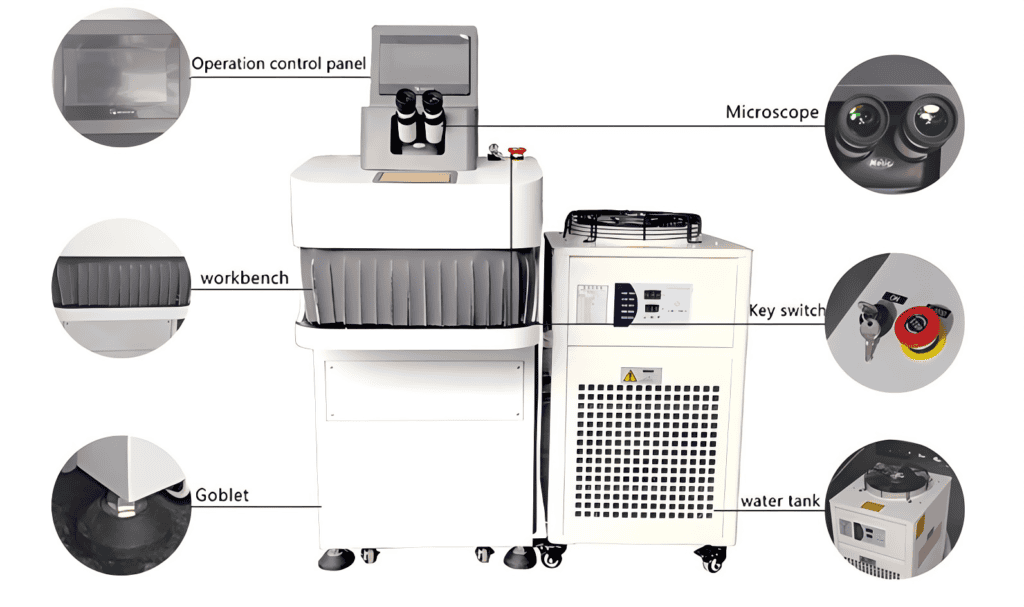

Features of jewellery laser welder

1. The most advanced automatic shading system eliminates light stimulation of the eyes during work.

2. 10X microscope magnification, cross cursor indication, and automatic shading with high-speed liquid crystal light valve.

3. The laser beam can realize time and energy splitting and carry out multi-beam processing simultaneously. The welding speed is significantly improved so that users can quickly complete the processing orders efficiently and with high quality.

4. Laser welding is seamless welding without external force. The energy is highly concentrated during welding, no consumables are required, and the toughness after welding is at least equivalent to the parent material. The laser energy, pulse width, and frequency are adjustable, making it suitable for welding various metal materials.

5. Fast speed, high efficiency, considerable depth, small deformation, small heat-affected zone, high welding quality, no pollution at the welding point, high efficiency and environmental protection.

6. The humanized design of laser welding is ergonomic, with no fatigue after long-term work, 24-hour continuous working ability, stable working performance of the whole machine, and maintenance-free operation.

Jewellery laser welder details

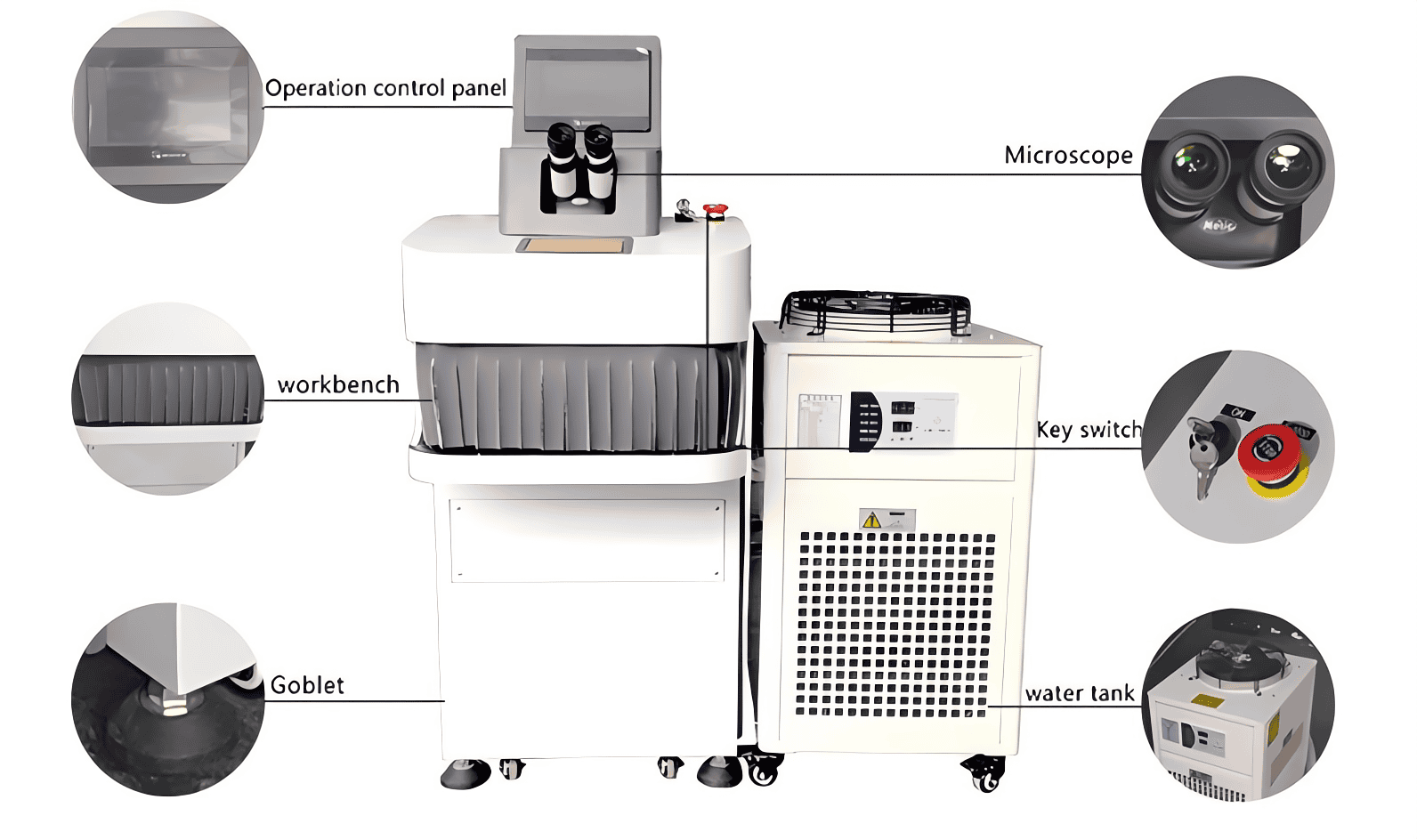

Microscope

10X microscope magnification makes it easier to observe the welding effect.

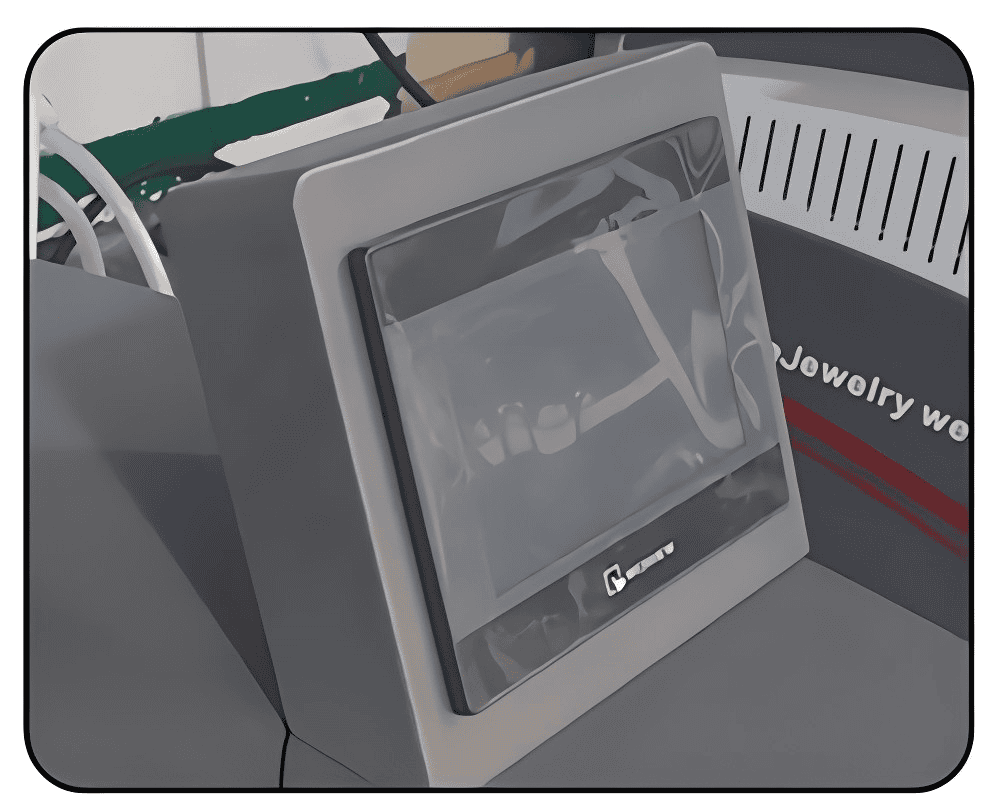

Operation Control Panel

It has a high-definition screen, is multi-language switchable, and only three parameters must be adjusted. It is simple to operate, so learn and use it immediately!

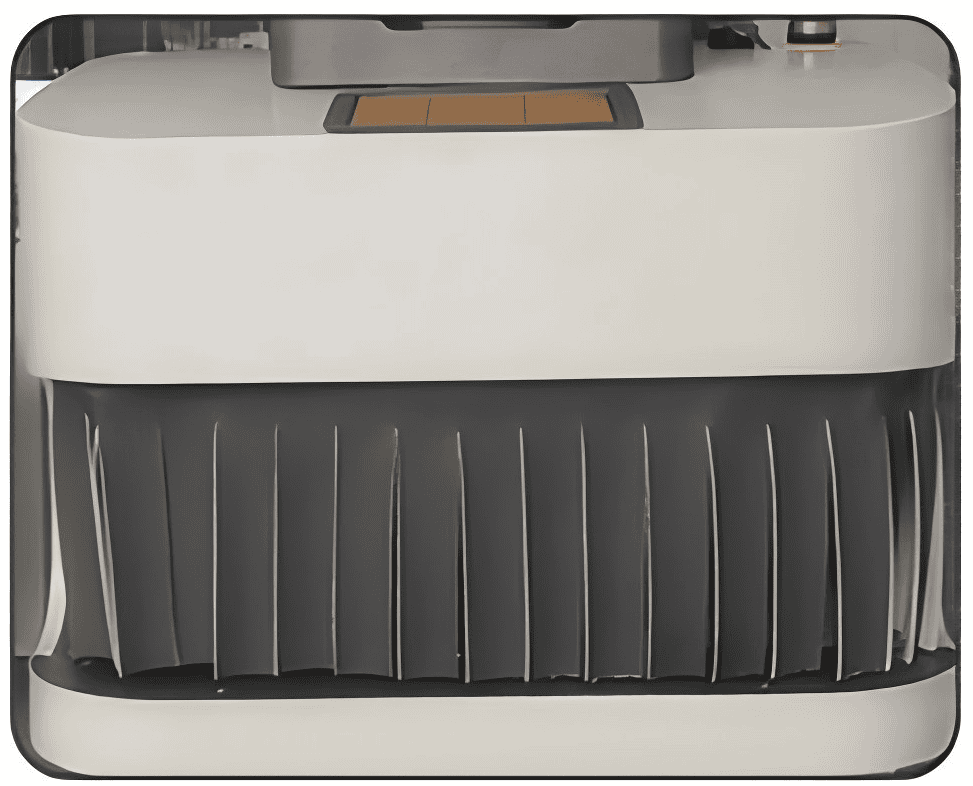

Workbench

Professional working cavity design is easy to clean and recover precious metals.

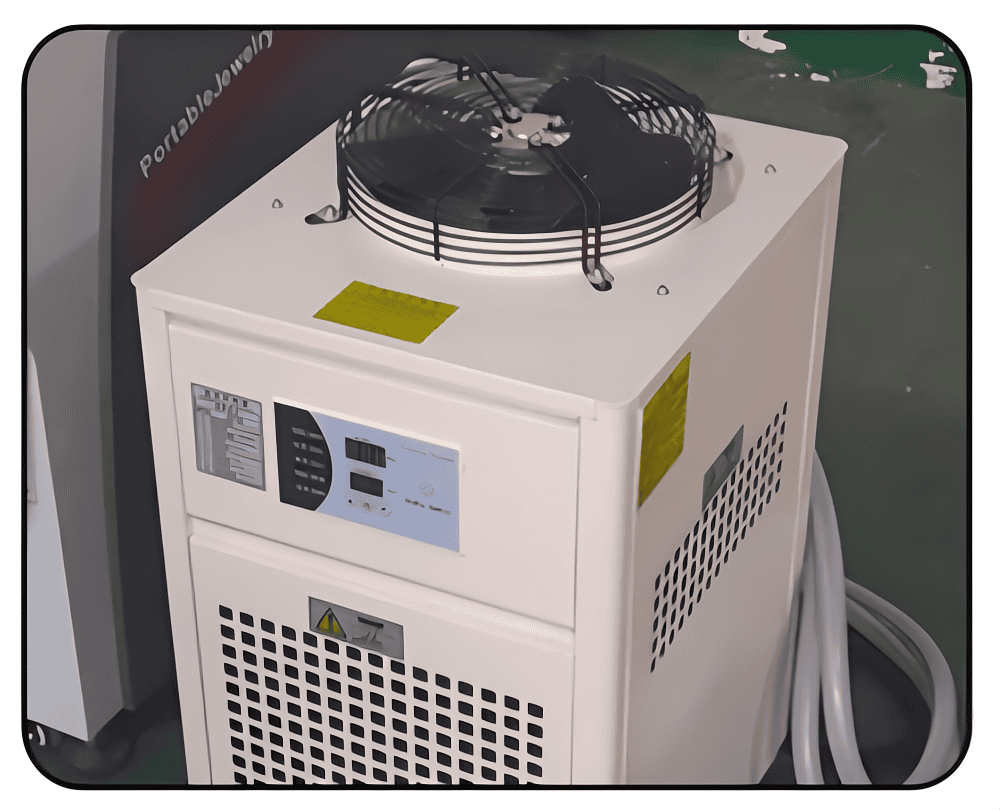

Water Tank

The cooling system ensures the equipment’s stable operation and controls the machine’s operating temperature.

Other models

Application Areas

Industry

After the jewellery laser welder was introduced into the jewellery industry, it became famous for its high speed, precision, and convenience. It has been used widely, gradually becoming indispensable and essential equipment for jewellery companies. It can also be used in electronic components, craft gifts, watches, auto parts, hardware, mould repair, medical equipment, and other industries.

Material

The jewellery laser welder is suitable for welding various metal materials and their alloys, such as platinum, K gold, silver, titanium, stainless steel, copper, and aluminium.

Service and Commitment

After-sales

We provide 1-3 years warranty and lifelong maintenance for our products. During the warranty period, any functional defects (except for human or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge the workpiece fee based on the actual situation.

Quality Control

We have employed a skilled and rigorous quality inspection team during the material procurement and production process.

Our quality control strictly tests 100% of all finished machines we deliver to the engineering department.

We will provide customers with detailed machine pictures and test videos before delivery.

OEM Service

With our rich experience, we warmly welcome customization and OEM orders. All OEM services are free of charge. We can customize machine design, function, colour, logo… for customers.

There is no minimum order quantity requirement. One unit can still enjoy wholesale price.

Privacy

Your personally identifiable information (such as your name, address, email address, bank information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions or requests for assistance will be responded to within 24 hours, even on holidays. If you have any urgent questions, please call us.

Payment Terms

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms include PayPal, Western Union, etc.

Document Support

Support all customs clearance documents: contract, packing list, commercial invoice, export declaration, etc.

Time to complete order

Machine production time is 7-10 days. Air freight time is 5-7 days, and sea freight is about 30 days. It depends on which shipping method you prefer.

Reviews

There are no reviews yet.