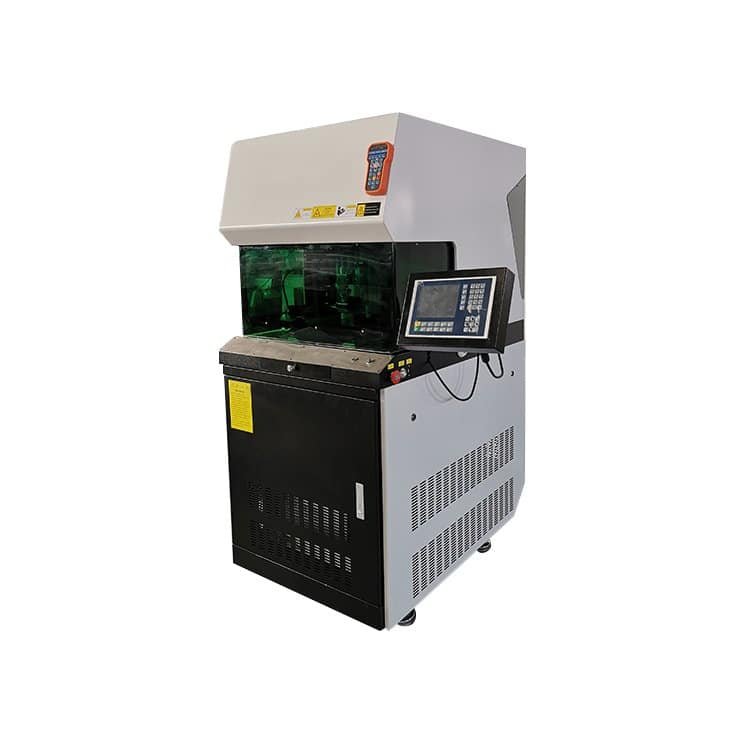

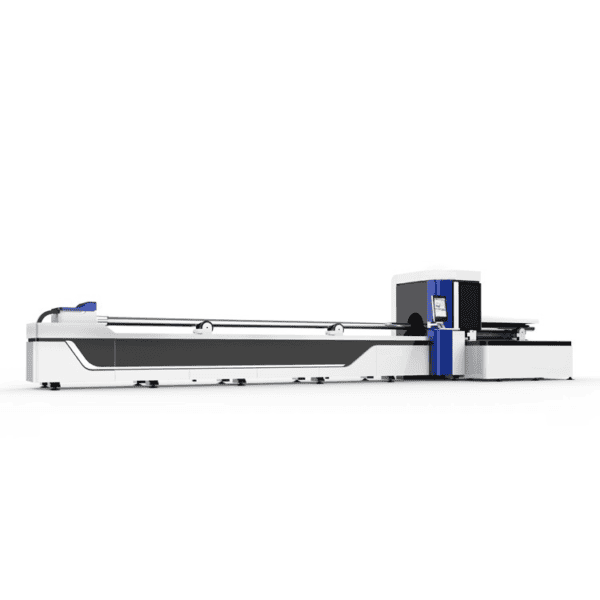

Are you planning to buy or customize a high-precision laser cutting machine? DAG high-precision laser cutting machine integrates multiple design concepts, high-speed manoeuvrability, and a follow-up dynamic focusing device to achieve automatic focus cutting of materials of different thicknesses. It is equipped with a high-precision CNC workbench controlled by a PC. It can perform high-precision cutting and punching during cutting by adjusting the laser frequency, pulse width, workbench speed, and moving direction. It adopts a fully enclosed design, which is safe, environmentally friendly, generous, beautiful, CE-compliant, and widely applicable! It is worth yours; welcome to inquire!

What is a high-precision laser cutting machine?

A high-precision laser cutting machine is a cutting equipment designed using laser technology and CNC technology. It has stable laser power, suitable beam mode, high peak power, high efficiency, low cost, safety, stability and easy operation.

High-precision laser cutting machines have no cutting force and no deformation during processing, no tool wear, and good material adaptability: whether it is a simple or complex part, it can be cut quickly and accurately at one time with a laser; its cutting gap is narrow (±0.02mm), cutting quality is good, the degree of automation is high, the operation is simple, the labour intensity is low, and there is no pollution: it can realize automatic cutting arrangement and nesting, improve material utilization, low production cost and good economic benefits.

Technical Parameters

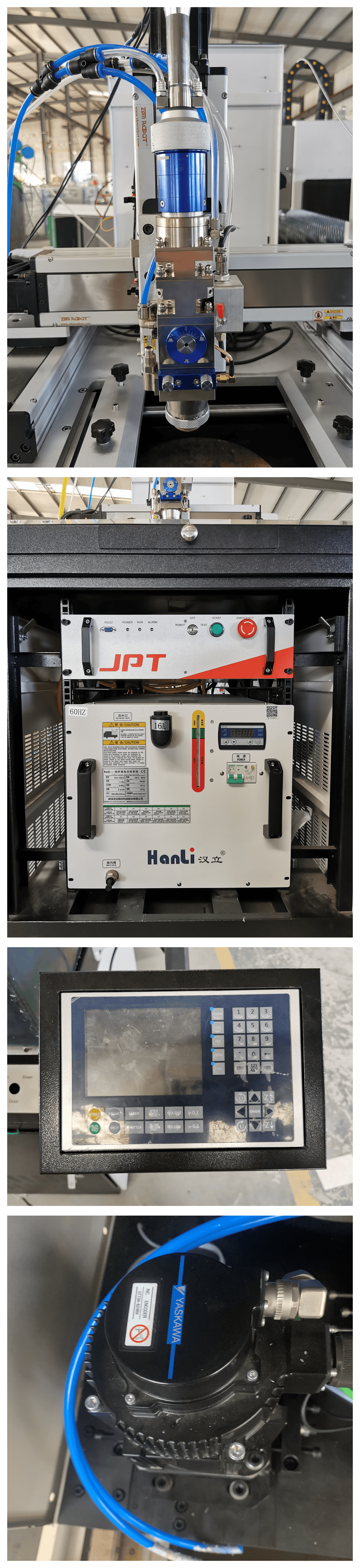

| Laser Source | Raycus/IPG/MAX/JPT(optional) |

| Laser Power | 500W1000W1500W /2000W/3000W (optional) |

| Laser Wave Length | 1060nm-1080nm |

| Working Area | 200*200mm(customizable) |

| Maximum Idle Running Speed | 100m/min |

| Position Accuracy | ±0.02mm/m |

| Position Speed | 80m/min |

| Minimum Line Width | ± 0.02mm |

| Cutting Thickness | ≦14mm |

| Control System | RUIDA |

| Position Type | Red dot |

| Power Consumption | ≤22KW |

| Working Voltage | 380V/50Hz |

| Auxiliary Gas | Oxygen, Nitrogen |

| Working life of fiber module | More than 100000 hours |

| Fiber laser cutting head | WANSHUNXING MN15 |

| Driver system | Yaskawa |

| Transmit system | Dual Rack & Pinion type |

| Rack system | Famous brand |

| Chain system | IGUS (Germany Brand) |

| Motor Reducer | Motoreducer(France Brand) |

| Water chiller unit | China |

| Automatic Oil lubrication | Yes |

| collection tray | Yes |

Features

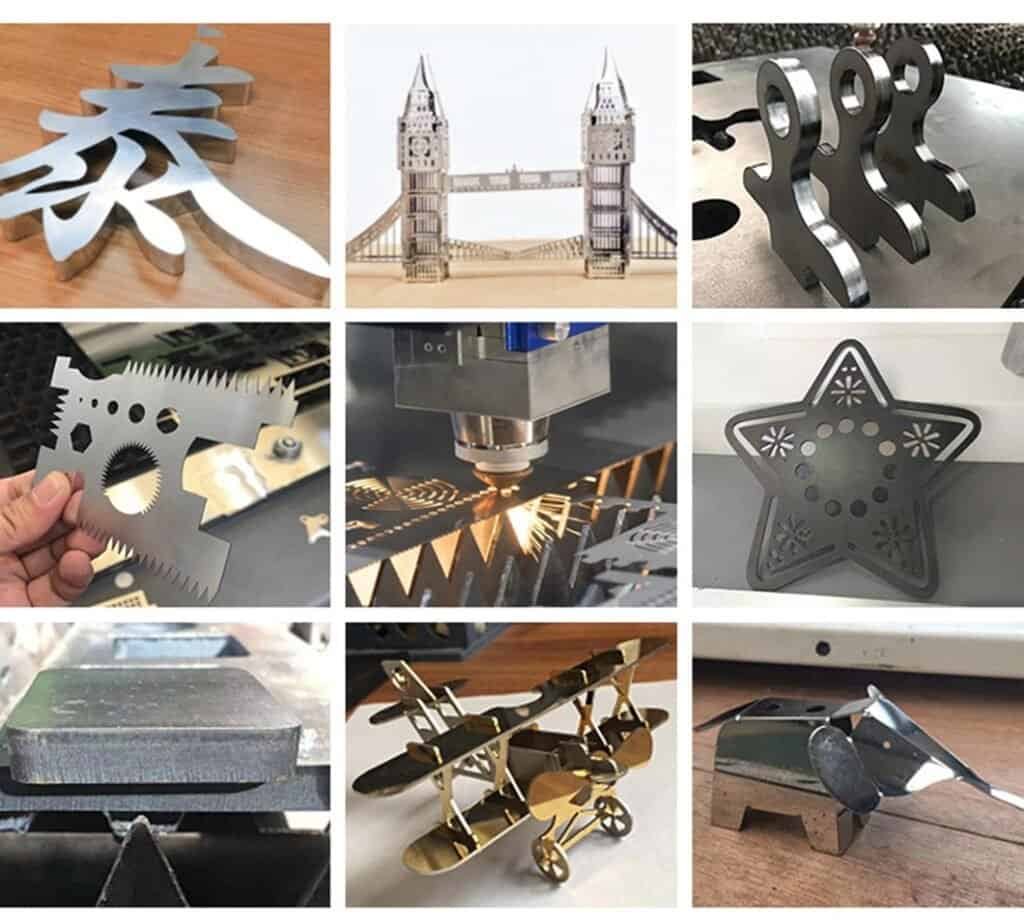

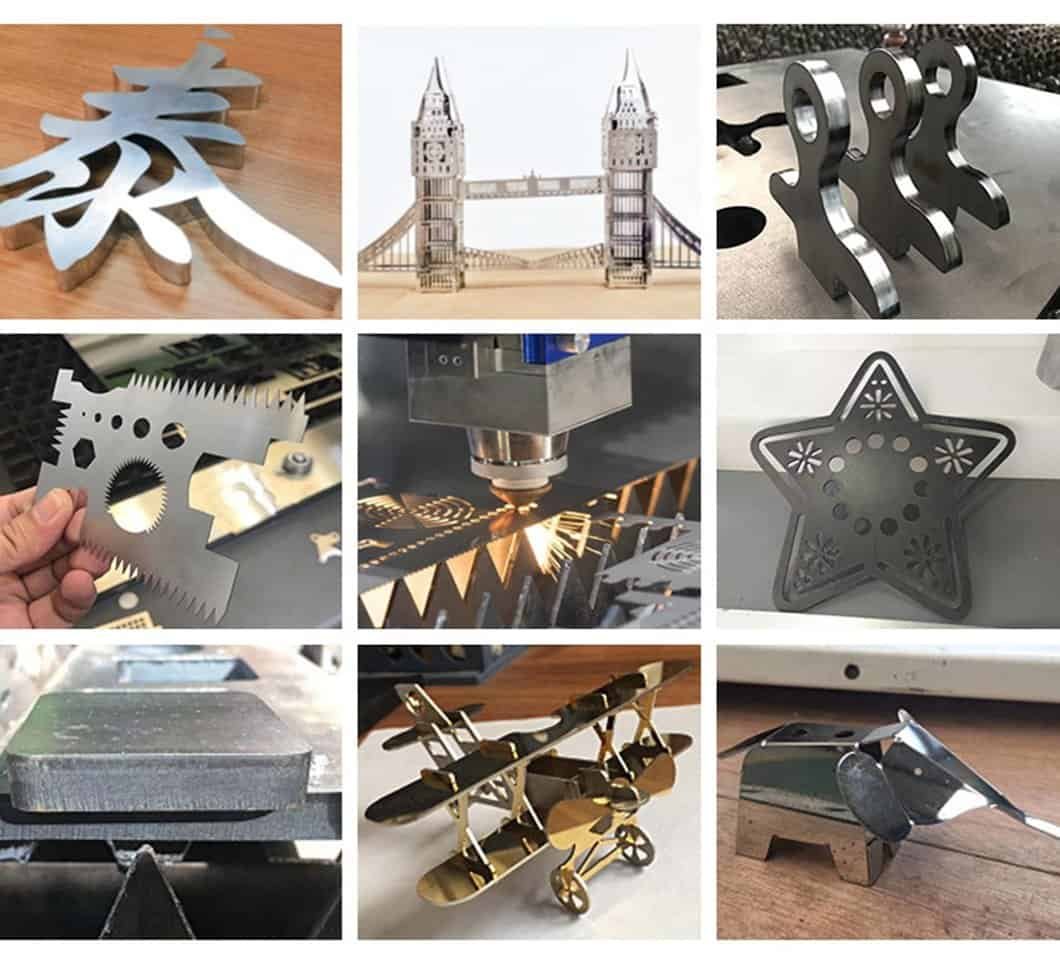

1. High performance: perfect cutting of stainless steel, tungsten steel, copper, alloy, cast iron, galvanized sheet, colour steel sheet, and sound insulation board.

2. High efficiency: can cut various metal plates within 8mm.

3. Low investment: the price of the whole machine is only 15,000 US dollars.

4. Diversity: the speed is more than 60 times that of the wire-cutting machine, with fast processing speed, high efficiency and good economic benefits.

5. The straight edge has a small cutting gap and a smooth cutting surface, which can obtain a large depth-to-diameter ratio and depth-to-width ratio.

6. Extremely small thermal deformation can be processed on various materials such as hard, brittle and soft.

7. There is no problem with tool wear and replacement and no mechanical quality change.

8. Easy to realize automation, can realize processing under special conditions.

Details

Applicable Materials and Industries

It is suitable for cutting and forming metal plates, precision cutting of stainless steel, carbon steel, brass, aluminum, and other metal materials, and sheet metal and spare parts processing companies that require medium and thick plates.

It is widely used in aviation, aerospace, weapons, ships, petrochemicals, medical equipment, instruments, microelectronics, jewellery, automobiles and other industries.

DAG At Your Service

Pre-Sales Service

• Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (PLT, AI) or mail us your workpiece; we will cut it in the factory and make a video to show you the cutting process and results or send you a sample to check the cutting quality.

• Drive solution design:

According to the customer’s product processing requirements, we can design a unique solution for customers to support higher manufacturing efficiency and better processing quality.

• Customized machine design:

We can modify our machines according to the customer’s application to achieve customer convenience and high production efficiency.

After-Sales Service

• As a professional CNC laser manufacturer and supplier, DAG will provide English training videos and user manuals for fiber laser machine installation, operation, maintenance and troubleshooting, and provide you with English training videos and user manuals by email, phone, mobile phone, etc. when you encounter installation, operation or adjustment problems.

• You can come to our factory for training. We will provide professional guidance and direct face-to-face practical training. We have assembly equipment, various tools and testing equipment here. Training time: 3~5 days (recommended).

• Our engineers will visit your local site for on-site guidance and training services. We must assist with visa processing and prepay travel and accommodation expenses before deployment and during service.

Warranty

• Three-year warranty for the whole machine, 18-month warranty for the laser, 12-month warranty for the chiller, and no warranty for the lens/mirror/nozzle.

• Long-term lifetime maintenance: The after-sales department will provide 24/7 English online support.

• We are responsible for providing free accessories during the warranty period, except for artificial damage.

• After the warranty period, the buyer is only responsible for the actual repair costs.

Frequently Asked Questions

If you need a free quote and detailed solution, please answer the following questions and let us know by email so that we can recommend the most suitable machine and quote you an affordable price.

• Do you need to cut metal plates, tubes, or both?

• If you need to cut tubes, what is the length, diameter, and maximum thickness of your tubes?

• What is the maximum working area required for cutting metal plates?

• How much do you plan to budget for customizing the machine?

• What will the processed material be used for (applicant)

• Which seaport is closest to you?

• Do you have experience with laser cutting?

• What is your online chat method, such as Skype, WhatsApp or WeChat

• Are you an end user or a dealer?

Reviews

There are no reviews yet.