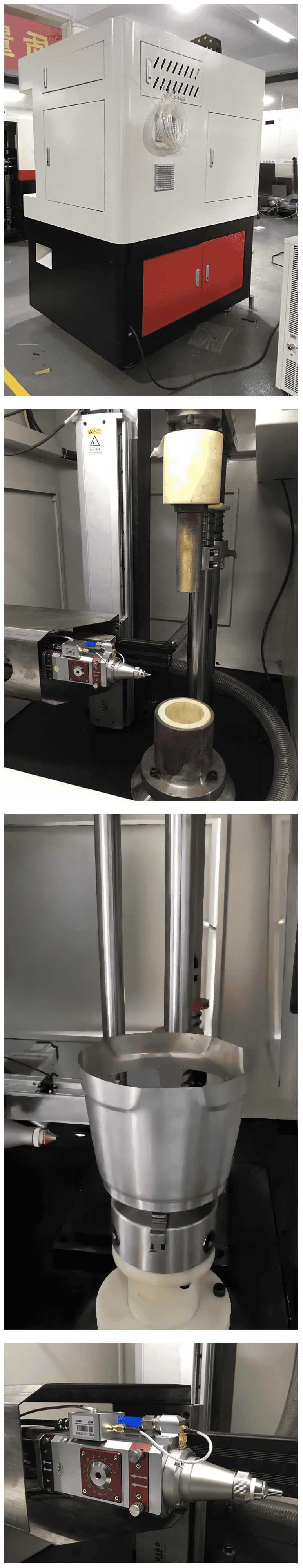

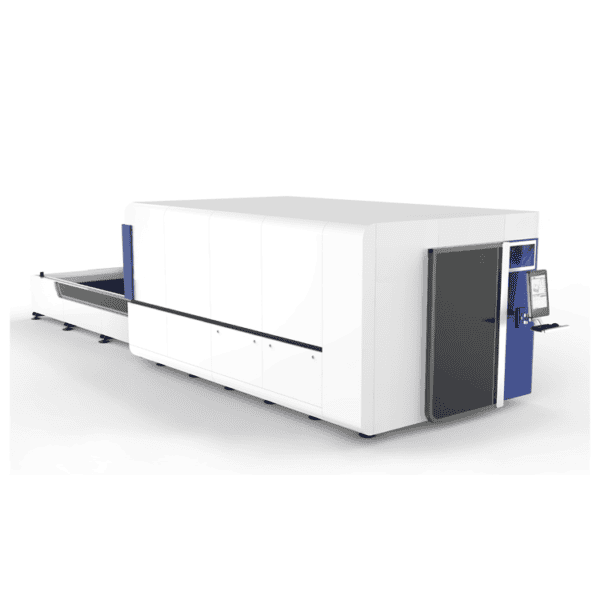

Cylindrical Material Laser Cutting Machine

The CNC metal laser cutting machine transmits the laser to the cutting head through a fibre laser, automatically controls the CNC system, and performs special-shaped processing on metals such as automotive parts, machinery, precision parts, gifts and crafts, tool processing, and decorations.

Technical Parameters

| Model | DG-CS1000 |

| Laser Power | 1000W/1500W/2000W |

| Laser Wavelength | 1070nm±5nm |

| Operating Mode | Continuous |

| Power adjustment range | 5-95% |

| Power instability | ≤2% |

| Transmission core diameter | 50um |

| Optical fiber cable length | 10m |

| Voltage | AC 220V±10% AC 380V±10% 50/60Hz |

| Cooling | Water Cooling |

Details

Advantages

CNC metal laser cutting machines have replaced traditional processing methods. They are convenient and fast to process three-dimensional parts, with low investment and maintenance costs, simple operation, reduced mold investment, greatly shortened the manufacturer’s development cycle, improved processing efficiency and cutting accuracy, and reduced production costs. They are a powerful tool to improve the competitiveness of the metal processing manufacturing industry.

Cutting samples

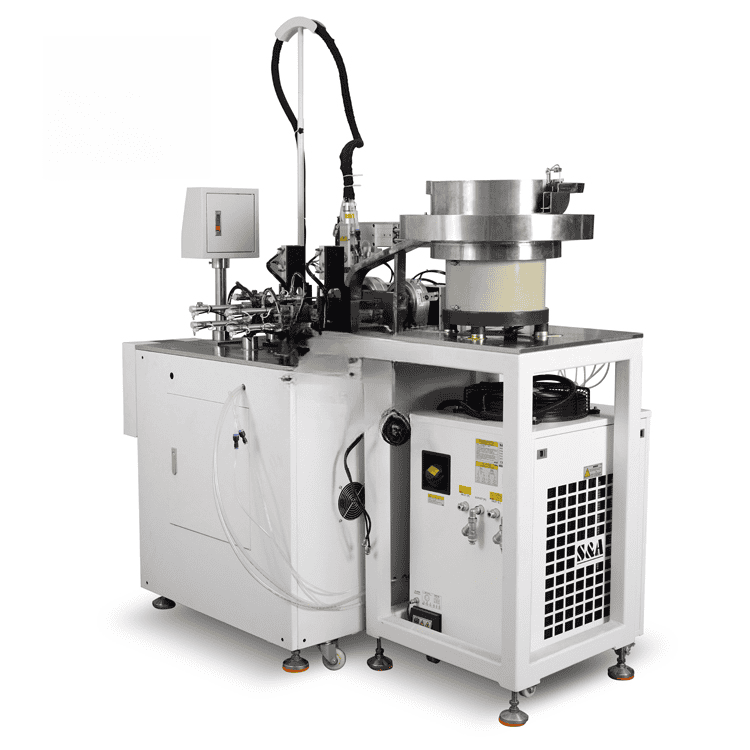

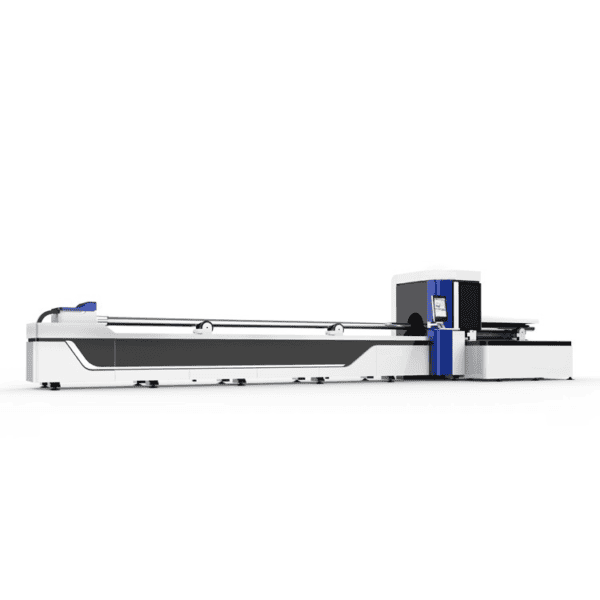

Cylindrical Lithium Battery Shell Laser Cutting Machine

Technical Parameters

| Model | DG-QG6018-3 |

| Laser source | Raycus IPG optional |

| Laser cutting head | Raytools WSX optional |

| Output power of laser source | 1000W 1500W 2000W 3000W optional |

| Cutting range | 600*600mm |

| Max positioning speed | 100m/min |

| X.Y axis max acceleration speed | 1.0G |

| Control system | Cpycut |

| Transmission | Double Drive Gear Rack |

| Guide rail | Taiwan Hiwin Guide Rail |

Cutting samples

DAG At Your Service

1. Pre-Sales Service

• Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (PLT, AI) or mail us your workpiece; we will cut it in the factory and make a video to show you the cutting process and results or send you a sample to check the cutting quality.

• Drive solution design:

According to the customer’s product processing requirements, we can design a unique solution for customers to support higher manufacturing efficiency and better processing quality.

• OEM Service

Due to our rich experience, customized and OEM orders are welcome. All OEM services are free of charge, and customers only need to provide us with their logo map, functional requirements, colours, etc.

No minimum order quantity requirements.

2. After-sales

Our company provides 1-3 years warranty and lifelong maintenance for our products. Products within the warranty period can be repaired or replaced free of charge (except for wearing parts) due to functional defects (except for human or force majeure factors). After the warranty period, our company only charges labour costs based on the actual situation.

3. Quality Control

We have a skilled and strict quality inspection team during the material procurement and production process.

All finished machines we deliver are 100% strictly tested by our quality control and engineering departments.

We will provide customers with detailed machine pictures and test videos before delivery.

4. Privacy

None of your personally identifiable information (such as your name, address, email address, bank information, etc.) will be disclosed or shared with any third party.

Contact Information: We will respond to all inquiries, questions, or requests for help within 24 hours, even on holidays. If you have any urgent questions, please feel free to call us.

5. Payment Terms

30% T/T deposit in advance, the balance to be paid before shipment.

6. Document Support

All customs clearance support documents: contract, packing list, commercial invoice, export declaration, etc.

If you have any questions, please get in touch with us; our sales managers are online 24/7 to receive your questions or requests and provide solutions within 12 hours!

Reviews

There are no reviews yet.