The DG series of downward-acting CNC bending machines is the most stale bending machine in a variable production environment. The high rigidity of the machine frame and the CNC system expand the machining range to realize high-speed and high-precision machining. High rigidity of the machine frame and CNC control system to better develop the processing range can realize high-speed,high-precision processing simultaneously, compared with the previous upper dynamic type, which is more energy-saving and stable. Improve the working environment and solve various bending machine angle problems simultaneously.

.png)

CNC Press brake with Upstroke Moving Technical Parameters

DG-3512 Technical Parameters

| Name | Unit | DG-3512 |

| Nominal force | KN | 350 |

| Bending length | MM | 1250 |

| Distance between side panels | MM | 1020 |

| Throat depth | MM | 200 |

| Ascent speed | MM/S | 46 |

| Bending speed | MM/S | 8 |

| Return speed | MM/S | 42 |

| Opening height | MM | 395 |

| Workbench (slider) stroke | MM | 100 |

| Number of cylinders | PCS | 1 |

| Main motor power | KW | 3 |

| Machine weight | KG | 1600 |

| Machine length | MM | 1440 |

| Machine width | MM | 1300 |

| Machine height | MM | 2100 |

| Fuel tank capacity | L | 26 |

.png)

Up Stroke Type(DG 6020)

DG-6020 Technical Parameters

| Name | Unit | DG-6020 |

| Nominal force | KN | 600 |

| Bending length | MM | 2000 |

| Distance between side panels | MM | 1700 |

| Throat depth | MM | 405 |

| Ascent speed | MM/S | 52 |

| Bending speed | MM/S | 8 |

| Return speed | MM/S | 46 |

| Opening height | MM | 395 |

| Workbench (slider) stroke | MM | 100 |

| Number of cylinders | PCS | 3 |

| Main motor power | KW | 5.5 |

| Machine weight | KG | 3800 |

| Machine length | MM | 2250 |

| Machine width | MM | 1440 |

| Machine height | MM | 2200 |

| Fuel tank capacity | L | 45 |

.png)

Up Stroke Type(DG 8025)

DG-8025 Technical Parameters

| Name | Unit | DG-8025 |

| Nominal force | KN | 800 |

| Bending length | MM | 2500 |

| Distance between side panels | MM | 2200 |

| Throat depth | MM | 405 |

| Ascent speed | MM/S | 52 |

| Bending speed | MM/S | 8 |

| Return speed | MM/S | 46 |

| Opening height | MM | 395 |

| Workbench (slider) stroke | MM | 100 |

| Number of cylinders | PCS | 3 |

| Main motor power | KW | 5.5 |

| Machine weight | KG | 4500 |

| Machine length | MM | 2580 |

| Machine width | MM | 1440 |

| Machine height | MM | 2200 |

| Fuel tank capacity | L | 45 |

.png)

DG-10030 Technical Parameters

| Name | Unit | DG-10030 |

| Nominal force | KN | 1000 |

| Bending length | MM | 3100 |

| Distance between side panels | MM | 2250 |

| Throat depth | MM | 405 |

| Ascent speed | MM/S | 52 |

| Bending speed | MM/S | 8 |

| Return speed | MM/S | 46 |

| Opening height | MM | 395 |

| Workbench (slider) stroke | MM | 100 |

| Number of cylinders | PCS | 3 |

| Main motor power | KW | 7.5 |

| Machine weight | KG | 6400 |

| Machine length | MM | 3340 |

| Machine width | MM | 1580 |

| Machine height | MM | 2380 |

| Fuel tank capacity | L | 72 |

CNC Upstroke Press Brake Advantages

1. One-screen operation function: A powerful computer integrates operation monitoring, fault detection, and learning assistance.

2. Multiple operating modes: Depending on the operator’s operating habits, direct programming, angle programming, or mixed programming modes can be selected.

3. Large-capacity storage: It is user-friendly, has customized functions, and is equipped with 40 sets of mould libraries and 200 product libraries.

4. Pullback and folding function: When processing parts, the backstop finger does not interfere with the moulding and can be retreated according to instructions.

5. Slow bending function: When processing complex parts and ultra-thin plates, you can choose different bending speeds to avoid damaging the workpiece.

6. Bending delay function: When processing large and complex workpieces, the command can be set to delay the start of the slider and rear gear finger.

7. Alignment bending function: When marking and bending are required, the machine can stop at the alignment position in one step, accurately and quickly.

8. Multiple lower limit functions: Different lower limit stop positions can be set according to other work steps during bending to improve work efficiency.

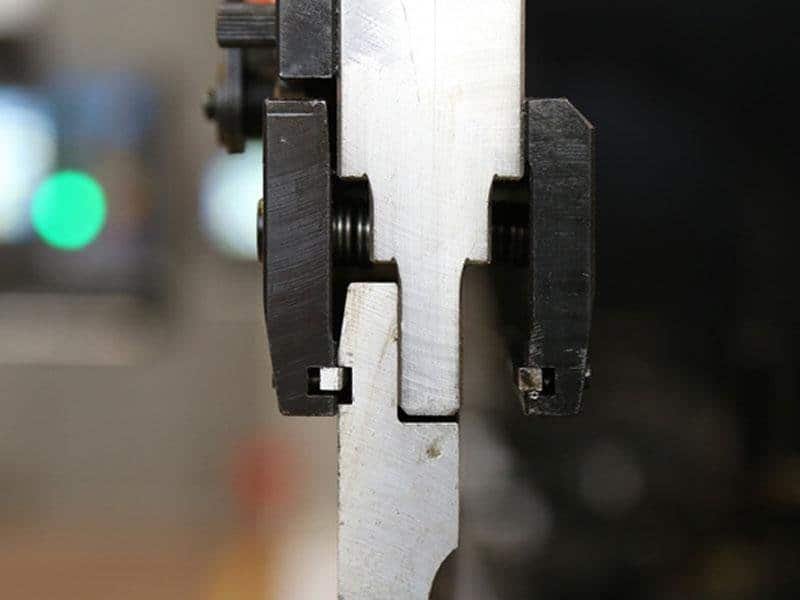

9. Mid-plate quick clamping: The mid-plate molded handle has anti-drop grooves. When closing the mould, turn the red handle left or right to load and unload the mould quickly.

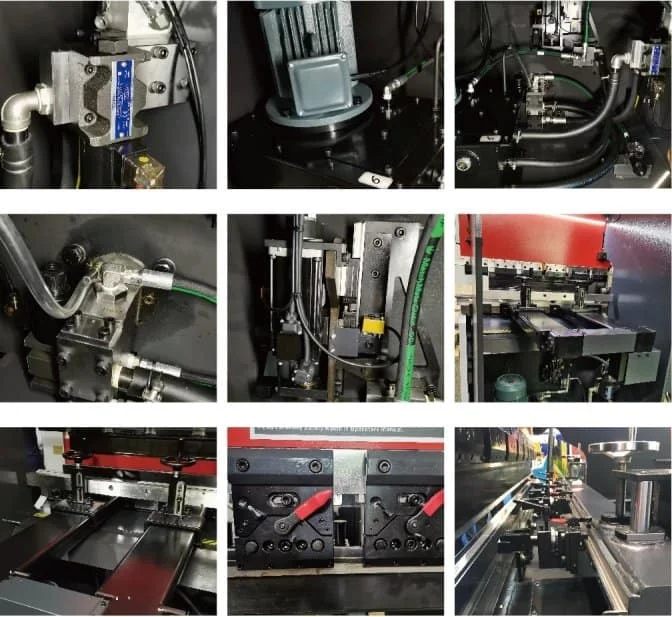

CNC Upstroke Press Brake Accessories

Controller with Rotating Arm

Operating Interface with Multi-Language

Balance Beam for Guide Rail Slide

Fast Clamps

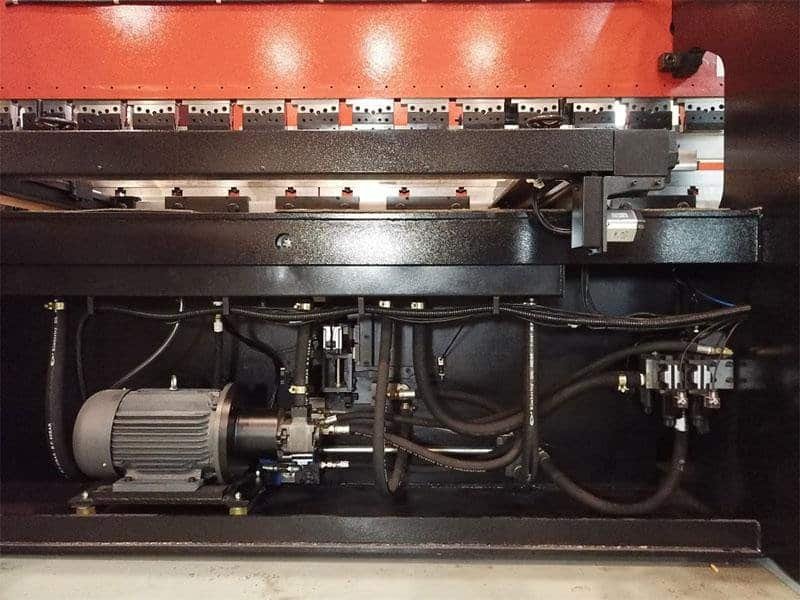

Hydraulic Circuit

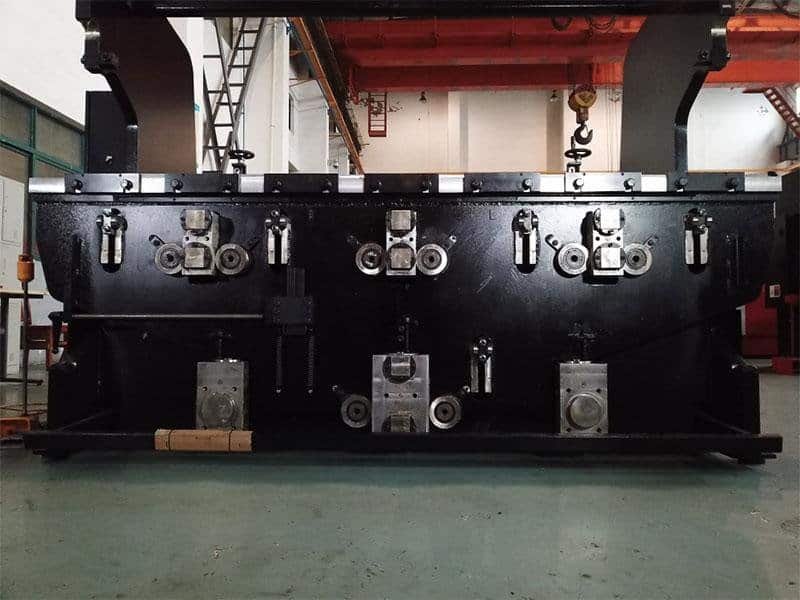

Hydraulic Clamping System

Machine Tool Drive Mechanism

Safety Device

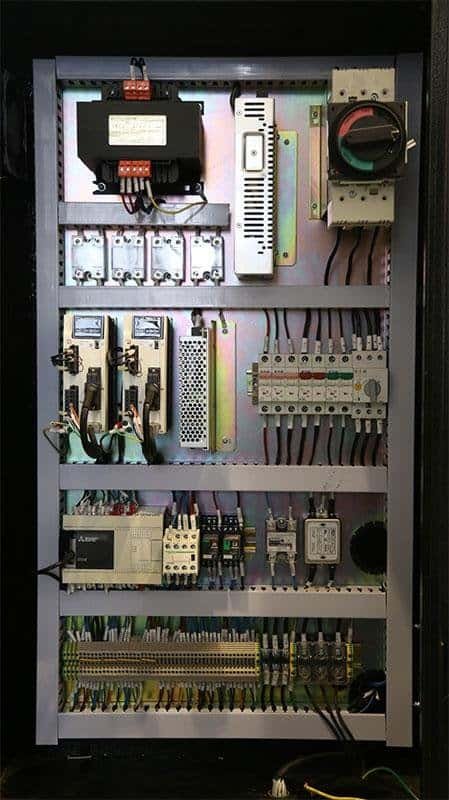

Electric Cabinet

CNC Upstroke Press Brake Applications

CNC bending machines use equipped moulds (general or special moulds) to bend metal sheets into workpieces of various geometric cross-section shapes in a cold state. They are plate-forming machines specially designed for cold-rolled plate processing. They have been widely used in plate-bending processing in automobiles, aircraft manufacturing, light industry, shipbuilding, containers, elevators, railway vehicles, electric power, cabinet processing, etc.

Pre-Sale Service

1.Free sample bending service:

For free sample bending/testing, please send us your CAD file or mail your product to us; we will bend it in our factory and make a video to show you the bending process and results or send you Samples are sent to you to check the bending quality.

2. Drive solution design:

Based on customers’ product processing requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better processing quality.

3. Customized machine design:

Depending on the customer’s application, we can modify our machines for customer convenience and high production efficiency.

After-Sale Service

1. As a professional CNC bending machine manufacturer and supplier, DAGCNC will provide English training videos and user manuals for installing, operating, maintaining, and troubleshooting downward-acting CNC bending machines. When you encounter installation, operation, or troubleshooting issues, you can contact us via email, phone, mobile, Whatsapp, Skype, 24/7 live chat, etc.

2. You can come to our factory for training. We will provide professional guidance and direct and practical face-to-face training. Here, we have assembly equipment, various tools and testing facilities. Training time: 3~5 days.

3. Our engineers will provide on-site guidance and training services in your area. We need your help with visa procedures, travel expenses, accommodation during travel, and pre-deployment services.

Warranty

1. 24-month warranty for the entire machine.

2. Lifetime maintenance: the after-sales department will provide 24/7 English online support.

3. Except for artificial damage, we are responsible for providing free accessories during the warranty period.

4. After the warranty expires, the buyer is only responsible for the actual cost of repairs.

-500x500.png)

Reviews

There are no reviews yet.