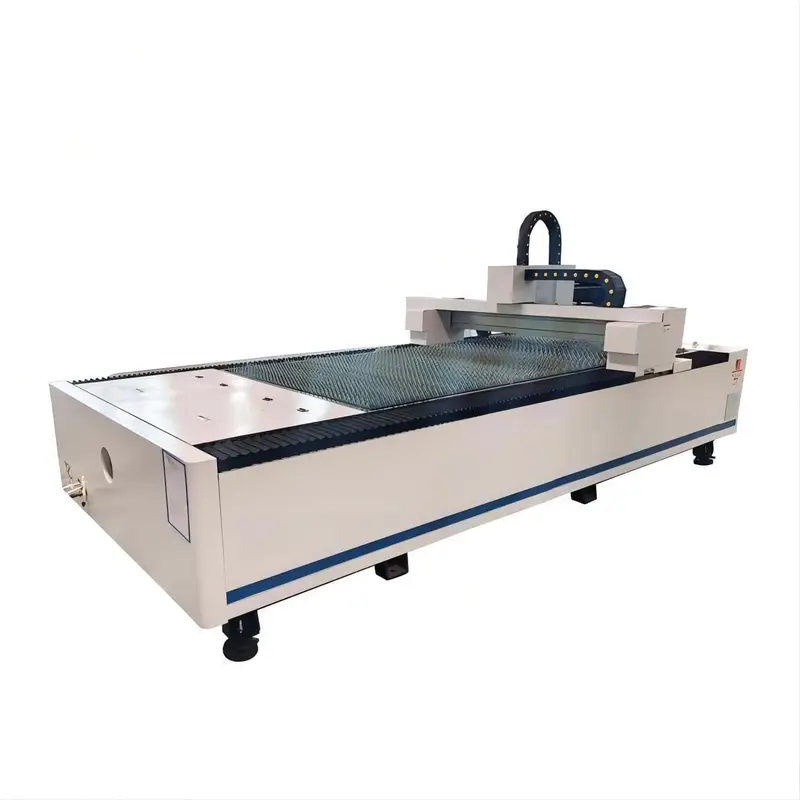

What is a 3015 CNC Metal Fiber Laser Cutting Machine?

3015 CNC metal fiber laser cutting machine refers to the maximum cutting area of 3 m×1.5 m. The 3015 laser cutting machine adopts a high-end rack and pinion dual drive configuration, a high-power fibre continuous laser and a professional CNC cutting system. Fiber laser cutting machines are mainly suitable for cutting metal materials. Different metal materials use different powers. Fiber laser cutting machines have fast cutting speed, high precision and sound effects. The critical point is non-contact laser cutting, which will not damage the object’s surface. Cutting design drawings are produced using widely used CAD software. After the drawing is completed, the CAD software can be used directly on the fibre laser cutting machine.

Product Parameter

| Laser source | Raycus IPG BWT Max optional |

| Output power of laser source | 1000W 1500W 2000W 3000W 6000W 10000W 12000W 20000W optional |

| Marking range | 3050/1510mm |

| Max positioning speed | 80m/min |

| X.Y axis max acceleration speed | 1.0G |

| Laser cutting head | Raytools/WSX |

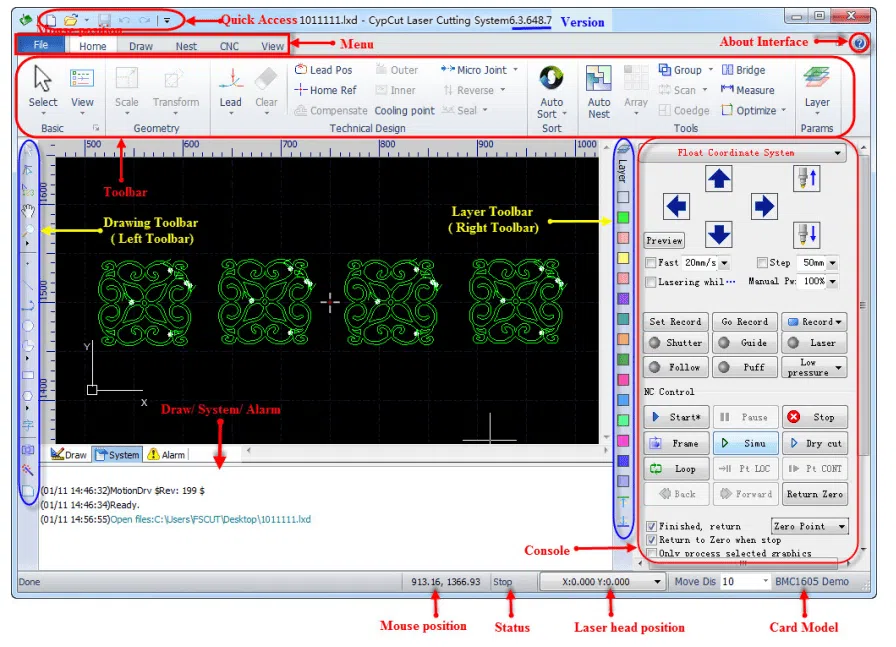

| Control system | Advantech / Cpycut optional |

| Power requirement | Yaskawa / Inovance optional |

| Transmission | Double Drive Gear Rack |

| Guide rail | Taiwan Hiwin Guide Rail |

| Electricity demand | 380V/50Hz |

| Working temperature | 0-50℃ |

| Cooling | Water cooling |

| Continuous working time | 24 Hours |

| Appearance size | 4700*2300*1800mm |

Details

3015 laser cutting machine internal parts

Machine Bed: Tube welding machine bed; Machine Beam: Aviation Aluminum beam

Laser Source: Raycus/IPG/BWT/Max optional

Water Chiller:China’s best brand S&A water chiller

Laser Head: Raytools/WSX optional

Servo Motor: Japan Yaskawa

CNC System: Cpycut/Advantech optional

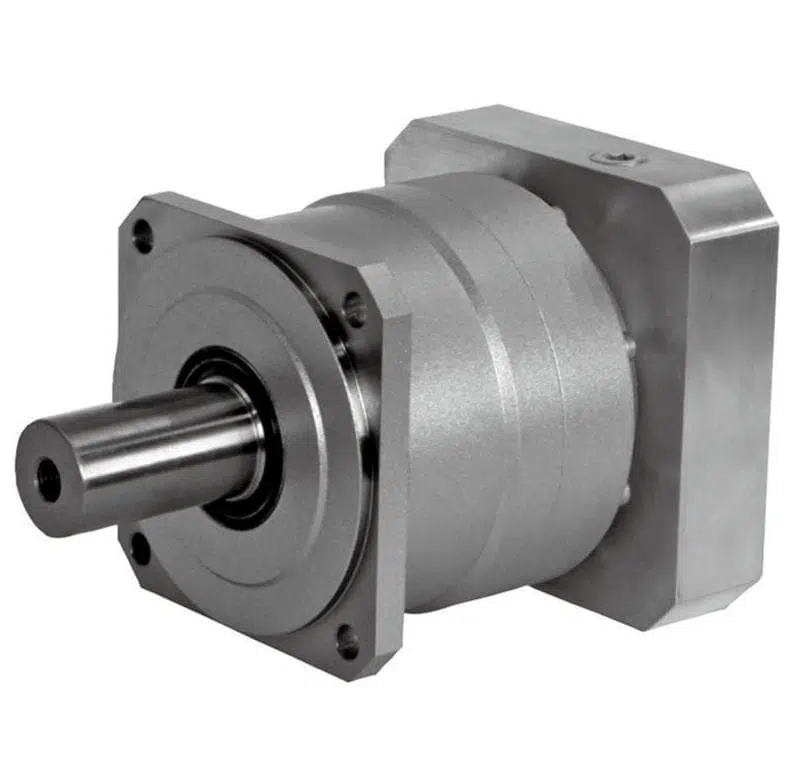

Japan SHIMPO Reducer

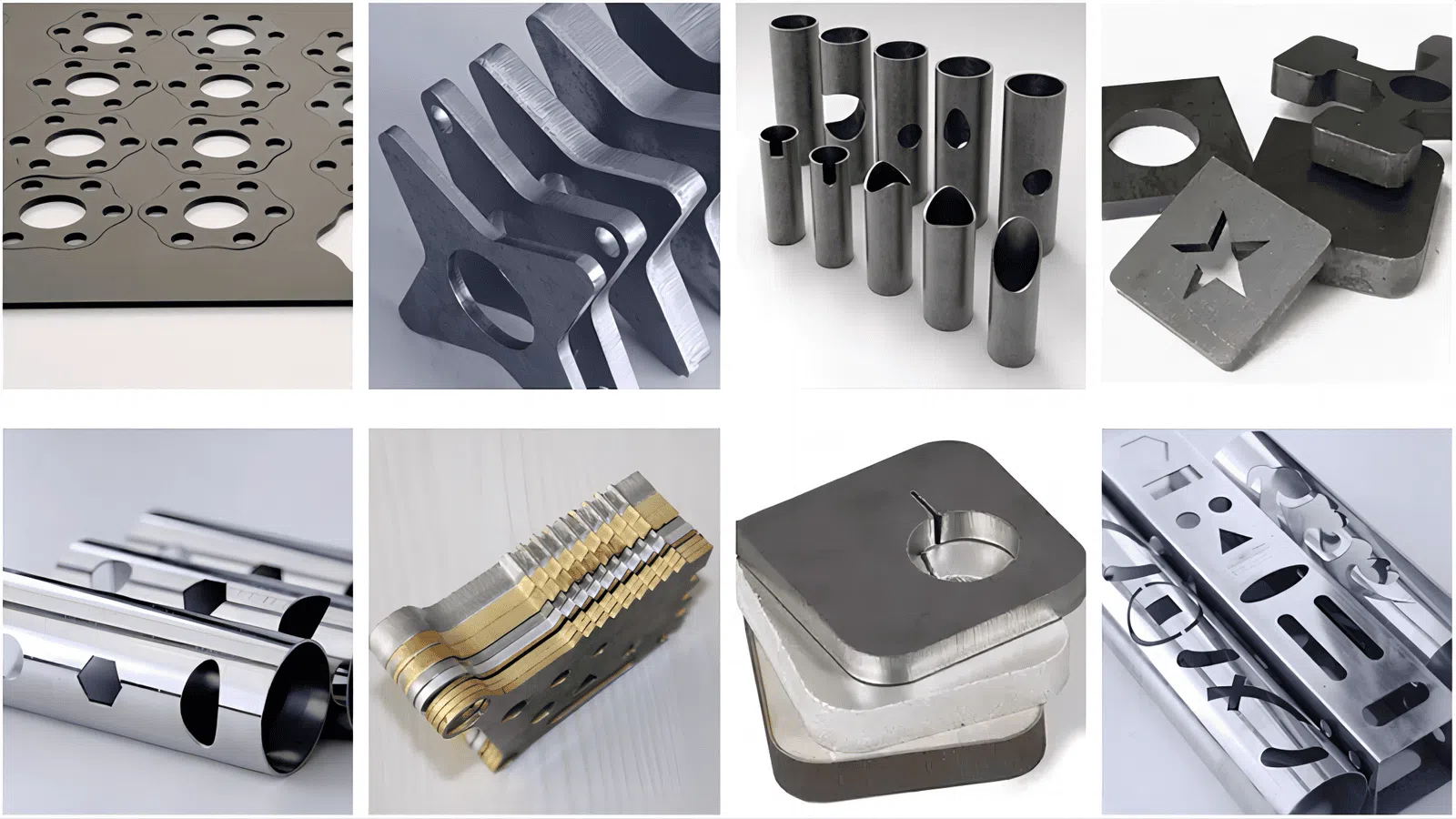

3015 CNC Metal Fiber Laser Cutting Machine Applications

Applied materials:

It is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminium alloy, titanium alloy, galvanized steel sheet, pickling board, aluminium zinc plate, copper, and many other materials.

Applied Industries:

Fibre laser cutting machines applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobiles, machinery, precision components, ships, metallurgical equipment, elevators, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

Find your optimal cutting parameters

500W fiber laser cutting machine

1. The entry-level 500W fiber laser cutting machine is used to cut carbon steel with a maximum speed of 13m/min and a maximum thickness of 6mm, stainless steel materials with a maximum speed of 13m/min and a maximum thickness of 3mm, aluminum plate materials with a maximum speed of 5.5m/min and a maximum thickness of 2mm, and copper plate materials with a maximum speed of 5.5m/min and a maximum thickness of 2mm.

1000W fiber laser cutting machine

2. The maximum speed of the 1000W fiber laser cutting machine for cutting carbon steel materials is 24m/min, and the maximum thickness is 10mm; the maximum speed for stainless steel materials is 24m/min, and the maximum thickness is 5mm; the maximum speed for aluminum plate materials is 10m/min, and the maximum thickness is 3mm; The maximum speed of copper plate material is 10m/min, and the maximum thickness is 3mm.

1500W fiber laser cutting machine

3.1500W lasers are typically used to cut stainless steel up to 6 mm thick, carbon steel up to 16 mm thick, and aluminum and copper up to 5 mm thick, with a maximum speed of over 35m/min.

2000W fiber laser cutting machine

4. The 2000W fiber laser cutting machine is used to cut carbon steel with a maximum speed of 28m/min and a maximum thickness of 16mm; stainless steel materials with a maximum speed of 28m/min and a maximum thickness of 8mm; aluminum plate materials with a maximum speed of 25m/min and a maximum thickness of 5mm; and copper plate materials with a maximum speed of 16m/min and a maximum thickness of 5mm.

3000W fiber laser cutting machine

5. The cutting capacity of the most popular 3000W fiber laser cutting machine is as follows: the maximum speed of carbon steel materials is 35m/min, and the maximum thickness is 20mm; the maximum speed of stainless steel materials is 35m/min, and the maximum thickness is 10mm; the maximum speed of aluminum plate materials is 43m/min, and the maximum thickness is 20mm. Thickness: 8mm; maximum speed of copper plate material: 35m/min; maximum thickness: 8mm.

4000W fiber laser cutting machine

6. The professional 4000W medium-power laser can cut stainless steel up to 12 mm thick, carbon steel up to 22 mm thick, aluminum up to 14 mm thick, and copper and brass up to 10 mm thick at a speed of more than 50m/min.

6kW fiber laser cutting machine

7. The commercial 6KW medium-power laser can release enough heat energy to cut carbon steel up to 25mm thick, stainless steel and aluminum up to 16mm thick, and copper and brass up to 10mm thick at a maximum speed of more than 60 m/min.

8kW fiber laser cutting machine

8. The industrial 8KW high-power laser can cut stainless steel and aluminum up to 25 mm thick, carbon steel up to 30 mm thick, and brass and copper up to 12 mm thick at a speed of more than 70m/min.

12,000W fiber laser cutting machine

9. The 12,000W high-power laser cutting machine is ideal for cutting carbon steel, stainless steel and aluminum up to 50mm thick, and copper and brass up to 20mm thick at a maximum speed of over 80 m/min.

15,000W fiber laser cutting machine

10. The 15,000W power supply is suitable for carbon steel and stainless steel with a maximum thickness of 60 mm, aluminum with a maximum thickness of 50 mm, and copper and brass with a maximum thickness of 30 mm. The maximum speed exceeds 90m/min.

20,000W fiber laser cutting machine

11. The 20,000W high-power laser can easily cut carbon steel with a thickness of up to 70mm, stainless steel with a maximum thickness of 80mm, aluminum with a maximum thickness of 80mm, brass and copper with a maximum thickness of 70mm, and the maximum speed exceeds 100 m/min.

30kW fiber laser cutting machine

12. The 30KW ultra-high-power laser can accurately cut stainless steel with a thickness range of more than 100 mm, carbon steel, aluminum, brass, and copper with a thickness of up to 80 mm, and its maximum speed exceeds 110m/min.

40,000W fiber laser cutting machine

13. 40,000W ultra-high-power lasers are usually used to accurately cut carbon steel, stainless steel, aluminum, brass, and copper with a more than 120 mm thickness speed of more than 120m/min.

60KW fiber laser cutting machine

14. The most potent 60KW laser cutting machine is usually used to cut carbon steel and stainless steel with thickness ranging from 16mm to 200mm at a speed of 0.05m/min to 15m/min.

DAG at Your Service

Pre-Sale Service

• Free sample cutting service:

For free sample cutting/testing, please send us your CAD files (PLT, AI) or mail your workpiece to us; we will cut it at the factory and make a video to show you the cutting process and results or send it to you. Sample to check cutting quality.

• Drive solution design:

Based on customers’ product processing requirements, we can design unique solutions for customers to support higher manufacturing efficiency and better processing quality.

• Customized machine design:

We can modify our machines according to customers’ applications to achieve customer convenience and high production efficiency.

After-Sales Service

• As a professional CNC laser manufacturer and supplier, DAG will provide English training videos and user manuals for fiber laser machine installation, operation, maintenance and troubleshooting, and provide you with English training videos and user manuals via email, phone, mobile phone, etc. when you encounter installation, operation Or Whatsapp, WeChat, Skype, 24/7 online chat etc. when adjusting issues.

• You can come to our factory for training. We will provide professional guidance and direct practical face-to-face training. We have assembly equipment, various tools, and testing equipment here. aining time: 3~5 days.

• Our engineers will visit your local site for on-site guidance and training services. We require assistance with visa processing and prepaid travel and accommodation expenses before deployment and during service.

Warranty

• The entire machine has a three-year warranty, the laser has an 18-month warranty, the chiller has a 12-month warranty, and the lens/mirror/nozzle does not have a warranty.

• Long-term lifetime maintenance: The after-sales department will provide 24/7 English online support.

• Except for artificial damage, we are responsible for providing free accessories during the warranty period.

• After the warranty period, the buyer is only responsible for actual repair costs.

Frequently Asked Questions

If you need a free quote and detailed solution, please answer the following questions and let us know via email so that we can recommend the most suitable machine and quote you an affordable price.

• Do you need to cut sheet metal, metal pipe, or both?

• If the pipe needs to be cut, what is your pipe length, diameter, and maximum thickness?

• What is the maximum working area required to cut sheet metal?

• For what purpose will the processed material be used (applicant on)

• Which seaport is closest to you?

• Do you have laser cutting experience?

• What is your online chat method, Such as Skype, WhatsApp, or WeChat

• Are you an end user or a reseller?

Reviews

There are no reviews yet.