Are you considering ways to reduce welding costs? Our nitrogen generator system is specifically designed to provide high-purity nitrogen gas for laser welding machines. The key is that the cost of producing nitrogen with this equipment is much lower than commercial nitrogen, with simple operation and extremely low maintenance costs. Our nitrogen generator system is affordable and fully functional, making it your best choice. Nitrogen generators: DAG-01, DAG-X01 (embedded), DAG-02, DAG-03, DAG-05, DAG-01/02/03S (PLC controlled), DAG-01/02/03L (PLC controlled, with refrigerated dryer). Start searching and purchasing the perfect nitrogen generator system immediately to meet your various needs and budget!

In the field of soldering, the main function of nitrogen is to exclude oxygen from the soldering process, to improve solderability and to prevent re-oxidation. Reliable and high-quality soldering requires, in addition to the appropriate solder, a flux. The role of the flux is mainly to remove oxides from the weld site before welding, preventing re-oxidation of the weld site and forming good wetting conditions for the solder to improve solderability. Nitrogen has become one of the most commonly used and important reaction gases in laser welding.

DAGCNC offers a wide range of laser welding nitrogen generators to fully meet your various needs and budgets.

Equipment type: DAG-01

Nitrogen flow rate: 20NL/min

Nitrogen purity: 95%-99.999%

Intake pressure: 0.6-0.8MPa

Nitrogen pressure: 0.5-0.8MPa

Air nitrogen ratio: 6.4:1

Power: 50W

Supply voltage: AC100-250V

Frequency: 50~60Hz

Rated intake: 1m³ /min

Equipment weight (kg): 59

Equipment size (mm): 450(L) * 500(W) * 780(H)

Equipment type: DAG-X01

Nitrogen flow rate: 20NL/min

Nitrogen purity: 95%-99.999%

Intake pressure: 0.6-0.8Mpa

Nitrogen pressure: 0.5-0.8Mpa

Air nitrogen ratio: 6.4:1

Power: 50W

Supply voltage: AC100-250V

Frequency: 50~60Hz

Rated intake: 1m³ /min

Equipment weight (kg): 42

Equipment size (mm): 630(L) * 170 (W) * 690 (H)

Equipment type: DAG-02

Nitrogen flow rate: 40NL/min

Nitrogen purity: 95%-99.999%

Intake pressure: 0.6-0.8Mpa

Nitrogen pressure: 0.5-0.8Mpa

Air nitrogen ratio: 5.6:1

Power: 60W

Supply voltage: AC100-250V

Frequency: 50~60Hz

Rated intake: 1m³ /min

Equipment weight (kg): 92

Equipment size (mm): 500(L) * 550(W) * 1070(H)

Equipment type: DAG-03

Nitrogen flow rate: 60NL/min

Nitrogen purity: 95%-99.999%

Intake pressure: 0.6-0.8Mpa

Nitrogen pressure: 0.5-0.8Mpa

Air nitrogen ratio: 5.87:1

Power: 60W

Supply voltage: AC100-250V

Frequency: 50~60Hz

Rated intake: 1m³ /min

Equipment weight (kg): 139.5

Equipment size (mm): 650(L) * 700(W) * 1300(H)

Equipment type: DAG-05

Nitrogen flow rate: 90NL/min

Nitrogen purity: 95%-99.999%

Intake pressure: 0.6-0.8Mpa

Nitrogen pressure: 0.5-0.8Mpa

Air nitrogen ratio: 5.9:1

Power: 60W

Supply voltage: AC100-250V

Frequency: 50~60Hz

Rated intake: 1m³ /min

Equipment weight (kg): 190

Equipment size (mm): 650(L) * 700(W) * 1300(H)

Equipment type: DAG-01S/02S/03S

Nitrogen flow rate: 20,40,60NL/min

Nitrogen purity: 95%-99.999%

Intake pressure: 0.6-0.8Mpa

Nitrogen pressure: 0.5-0.8Mpa

Air nitrogen ratio 6.4:1, 5.6:1, 5.9:1

Power: 56W, 66W, 70W

Supply voltage: AC100-250V

Frequency: 50~60Hz

Rated intake 1m³ /min

Equipment weight (kg): 113.2, 122.5, 150.5

Equipment size L*W*H (mm): 500 * 600 * 1090; 500 * 600 * 1000; 580 * 590* 1310

Equipment type: DAG-01L/02L/03L

Nitrogen flow rate: 20,40,60NL/min

Nitrogen purity: 95%-99.999%

Intake pressure: 0.6-0.8Mpa

Nitrogen pressure: 0.5-0.8Mpa

Air nitrogen ratio 6.4:1, 5.6:1, 5.9:1

Power: 1153W, 1236W, 1170W

Supply voltage: AC190-240V

Frequency: 50~60Hz

Rated intake 1m³ /min

Equipment weight (kg): 130, 140, 168 Equipment size L*W*H (mm): 580 * 590* 1310

Device Name: Air dryer

Processing air volume: 1.5Nm 3

Use pressure range: 0.6-1.0Mpa

Air connection diameter: DN25mm

Compressor power: 0.75HP

Intake air temperature: ≤45℃

Pressure loss: ≤0.02Mpa

Dew point: 3一10℃

Voltage/Frequency: 220/50 V/Hz

Product weight (kg): 40

Equipment size (mm): 730(L) * 390(W) * 700(H)

Unit model: DG-7.5YA2-I

Rated volume flow : 1.1m³/min

Rated exhaust pressure: 0.8

Cooling method: Air cooling

Exhaust oil content: ≤3ppm

Compression stage: Single stage

Operation noise d B(A)+2: ≤62

Outlet pipe diameter: G1/2

Power supply: Three-phase 380V/50Hz

Pressure MPa: 0.1033

Starting mode: Frequency start

Overall dimensions: 1300*620*1460mm

Unit weight: 210kg

Unit model: DG-7.5YA3-I

Rated volume flow : 1.1m³/min

Air Dryer: 1.5m³/0.8mpa

Rated exhaust pressure: 0.8

Cooling method: Air cooling

Exhaust oil content: ≤3ppm

Compression stage: Single stage

Operation noise d B(A)+2: ≤62

Outlet pipe diameter: G1/2

Power supply: Three-phase 380V/50Hz

Pressure MPa: 0.1033

Starting mode: Frequency start

Unit weight: 265kg

Overall dimensions(mm): 1440(L)*730(W)*1390(H)

Volume (L): 600/1000

Working Pressure (Bar): 8/10/12.5

Design Temperature (℃): 150

Height (mm): 2090/2180

Inside Diamenter (mm): 650/800

Net Weight (kgs): 143/168 /205/209/238/240

Air Inlet (DN): 40

Outlet (DN): 40

Connection (DN): 40

Safety (DN): 20

Value (DN): 20

Connection (DN): 20

Drainer (DN): 15

Connection (DN): 15

Nitrogen is the most abundant gas in the air, comprising 78.08% of the atmosphere, followed by oxygen at 20.95% and other gases at 0.97%. Nitrogen is colourless, odourless, transparent, and chemically inert, making it a sub-inert gas. At room temperature, it hardly reacts with other substances. High-purity nitrogen is often used as a protective gas or preservative in environments shielded from oxygen or air. However, under high-temperature and high-energy conditions, it can react chemically with certain substances to produce new substances useful to humanity.

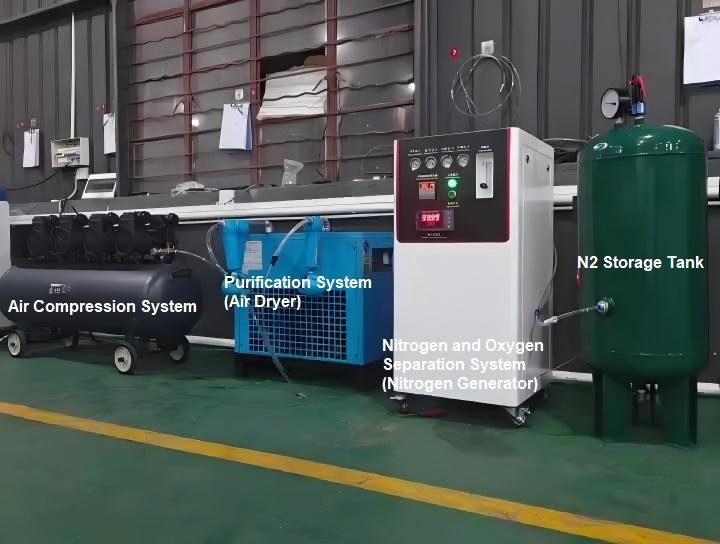

The air compressor compresses the raw air into a high-pressure air pressure of 0.8 MPa and sends it to an air buffer tank for pressure stabilisation.

The stabilised compressed air first passes through a C-grade filter to remove most oil, water, and dust. It then passes through a refrigerated dryer for freeze-drying, reducing the dew point of the compressed air to 2-10°C and removing a large amount of moisture. It then passes through a T/A-grade filter to further remove oil, water, and dust, reducing the oil content to ≤0.01 ppm and the dust content to ≤0.01 μm. It then passes through an adsorption dryer for deep water removal. It then passes through an H-grade activated carbon filter to remove harmful gases such as acids and alkalis, as well as fine oil mist, reducing the oil content to ≤0.001 ppm. Finally, a TR-grade filter removes dust.

Clean compressed air first enters the air process tank, then enters the bottom of a pressure swing adsorption nitrogen generator filled with carbon molecular sieve through a pipeline. After being dispersed by a specially designed equaliser diffuser, the airflow evenly enters the adsorption tower for the separation of oxygen and nitrogen through adsorption. Nitrogen is then produced from the top of the adsorption tower and sent to the nitrogen process tank for storage. A small amount of finished nitrogen enters the regeneration tower to purge the carbon molecular sieve, removing adsorbed impurities (primarily oxygen) and regenerating it. The two adsorption towers operate alternately, continuously feeding feed air and producing nitrogen.

Pressure Swing Adsorption (PSA) utilises the different diffusion rates of oxygen and nitrogen in air within a carbon molecular sieve, causing oxygen molecules to adsorb within the sieve while nitrogen molecules are concentrated in the gas phase, achieving air separation. Furthermore, the carbon molecular sieve’s oxygen adsorption capacity increases with increasing ambient pressure and decreases with decreasing pressure. This cyclical process of adsorption under pressure and oxygen desorption under reduced pressure to separate air is called PSA nitrogen production.

The adsorbent is the core component of nitrogen generation equipment. A commonly used adsorbent is carbon molecular sieve, primarily composed of elemental carbon. It appears as a black, cylindrical solid (1-2 mm in diameter, 2-5 mm in height). Because it contains numerous micropores (4 angstroms in diameter) with a strong instantaneous affinity for oxygen molecules, it is often used to separate oxygen and nitrogen from the air, which is then used to produce nitrogen through a pressure swing adsorption system.

Carbon molecular sieves separate nitrogen and oxygen based on the slight difference in the kinetic diameters of O₂ and N₂. Oxygen molecules have a smaller kinetic diameter, allowing them to diffuse faster through the pores of the carbon molecular sieve. Nitrogen molecules have a larger kinetic diameter, allowing them to diffuse more slowly. Ultimately, high-purity nitrogen is concentrated in the adsorption tower.

1. Flow Meter: Controls the nitrogen outlet flow rate. Note: Appropriately reducing the flow rate can increase nitrogen concentration.

2. Programmable Time Relay: Manages the operating sequence and pressure relief time of Towers A and B (A and B tanks).

3. Default Value: Factory-set optimal settings; user adjustment is generally not required.

4. Inlet: Use an 8mm tube for air intake. Requirement: Before connecting to the nitrogen generator, the source gas must be dehydrated and degreased to ensure optimal system performance and lifespan.

5. Nitrogen Outlet: Use a 6mm tube for nitrogen output. Purpose: If the outlet nitrogen meets the required quality standards, it can be used directly.

6. Pressure Gauge: Monitors the inlet pressure before entering the nitrogen generator. Normal range: The pressure should be maintained between 0.6 and 0.8 MPa.

7. Nitrogen Pressure Gauge: Displays the real-time pressure within the nitrogen storage tank. Tower A and Tower B Pressure Gauges: Monitor the pressure within the carbon molecular sieve tanks in Towers A and B. Operation: At any time, one tower is in operation (working state), and the other tower is depressurised or maintained at a low pressure state to regenerate the molecular sieve.

Nitrogen Generators for Laser Welding: Nitrogen generators play a vital role in the laser welding process, providing high-purity nitrogen to create an inert atmosphere, protect weld quality, and improve overall efficiency.

1. Cost Savings: Nitrogen generators can significantly reduce costs compared to purchasing nitrogen from compressed cylinders.

2. High Purity: They produce high-purity nitrogen suitable for a wide range of applications, ensuring quality and reliability.

3. Long Service Life: Nitrogen generators are low-maintenance and durable, providing a reliable and cost-effective nitrogen supply solution.

4. Convenience: Nitrogen can be generated on demand, eliminating the need to wait for deliveries or refill cylinders.

5. Improved Safety: Eliminating the need to handle high-pressure cylinders reduces the risk of accidents and ensures a safer working environment.

6. Customizability: Nitrogen generators can be customised to meet specific industry needs and application requirements.

Stable Weld Quality: Prevents porosity and defects caused by oxygen contamination. Supply on demand: No need to wait for a gas supply. Cost saving: Reduce operating costs in the long term.

1. What is a nitrogen generator?

A nitrogen generator is a machine that produces nitrogen on-site by separating it from compressed air. It typically uses technologies such as pressure swing adsorption (PSA) or membrane separation to produce high-purity nitrogen for a variety of applications, including laser welding.

2. How is a nitrogen generator used in laser welding?

In laser welding, a nitrogen generator provides high-purity nitrogen to protect the weld area from oxidation during the welding process. The nitrogen creates an inert atmosphere around the weld, ensuring a clean, high-quality, and strong weld. A nitrogen generator uses PSA or membrane separation technology to separate nitrogen from air and deliver it at the required purity and flow rate.

3. What is the required nitrogen purity for laser welding?

Laser welding typically requires nitrogen purity between 99.99% and 99.999%. This high purity ensures the weld area is oxygen-free, preventing oxidation and ensuring a clean, high-quality weld.

4. Why should I use a nitrogen generator instead of cylinders?

Using a nitrogen generator offers many advantages: Cost savings: Avoid the recurring costs of purchasing and refilling cylinders. On-demand supply: Generate nitrogen whenever you need it, ensuring continuous operation. Improved safety: Reduce the risks of handling and storing high-pressure cylinders. Convenience: Eliminate the need to rely on an external nitrogen supplier, saving time and effort.

5. What nitrogen flow rate is required for laser welding?

The nitrogen flow rate required for laser welding depends on the scale of the welding operation and the specific equipment used. Typical flow rates range from 10 Nm³/h to 500 Nm³/h, with customization options available to meet specific needs.

6. What is the typical lifespan of a nitrogen generator?

A well-maintained nitrogen generator can last 10-15 years or more, depending on the model and usage. Regular maintenance, such as changing filters and monitoring molecular sieves, ensures long-term reliability and performance.

7. Can I customize a nitrogen generator for my specific welding needs?

Yes, nitrogen generators are highly customizable. Purity, flow rate, and pressure can be customized to meet the needs of different industries and welding applications, ensuring optimal system performance.

8. What maintenance does a nitrogen generator require?

Nitrogen generators require minimal maintenance. Routine maintenance includes: replacing filters as needed; inspecting and cleaning components such as valves and instruments; and periodically replacing the carbon molecular sieve (in PSA systems). Most maintenance tasks are simple and can be performed by in-house personnel with minimal training.

9. What are the advantages of a nitrogen generator over traditional nitrogen supply methods?

Cost-effective: Reduces reliance on expensive nitrogen cylinders and transportation costs. Convenient: Provides a continuous on-site nitrogen supply, ensuring continuous operation. Safe: Eliminates the need to transport and store high-pressure cylinders, reducing the risk of accidents. Environmentally friendly: Nitrogen is generated on-site, resulting in no emissions or waste.

10. How do I choose the right nitrogen generator for laser welding?

When selecting a nitrogen generator for laser welding, consider the following factors: The nitrogen purity required for the specific welding application. The flow rate that matches the output requirements of the laser welding machine. Size and space requirements for integrating the generator into existing equipment. Budget and energy efficiency for long-term operational savings.

If you need to buy a CNC metal machine tool, DAG is your first choice. Please send us your detailed requirements and get an instant quote now.

© 2024 Shenzhen DAG Technology Industrial Co., Ltd.All Rights Reserved.

WhatsApp us