DΛGCNC | PRODUCTS | Metal Laser Welding Machine | Page 2

Are you considering buying an affordable welding machine that can combine metal parts without causing pollution? The answer is yes, it is the laser welding machine, which can meet the needs of spot welding, butt welding, lap welding, T-butt welding, seam welding, narrow welds, deep welds and kiss welding in the manufacture of metals (gold, silver, titanium, nickel, tin, copper, aluminum, iron, stainless steel, carbon steel, etc.). Laser welders are replacing traditional MIG and TIG welders with fantastic efficiency and powerful functions. They apply miniature, densely arranged, precise and heat-sensitive parts in jewelry, kitchenware, aerospace, automobiles, new energy batteries, electronic equipment and components, and commercial, shipbuilding, chemical and medical industries. The best-selling laser welders selected by DAGCNC for beginners and professionals, from entry-level handheld laser welding guns to automatic laser welding systems with CNC controllers and professional 3D laser welding robots. DAGCNC offers various types of laser welders with laser sources of YAG and fibre, power of 100W, 200W, 1000W, 2000W and 3000W, etc., suitable for machinists, operators, DIY enthusiasts, manufacturers, artisans, beginners, homeowners, shop owners, commercial users and industrial manufacturers. Start looking and buying the perfect laser welder for your every need and budget now.

Laser welding is a new type of welding method, mainly for welding thin-walled materials and precision parts. It can realize spot welding, butt welding, lap welding, sealing welding, etc. It has a high aspect ratio, small weld width, small heat-affected zone, small deformation, fast welding speed, smooth and beautiful weld, no need for post-welding treatment or only simple treatment, high weld quality, no pores, can be precisely controlled, small focus spot, high positioning accuracy, and easy to realize automation. DAGCNC provides various types of metal laser welders to meet your various needs and budgets fully.

The DG-HS series lightweight handheld laser welding machine is designed to be light and flexible, easy to carry and operate, with a deep weld and beautiful appearance. It is suitable for a variety of complex working environments and confined spaces. Now on sale at a promotional price, Welcome to inquire!

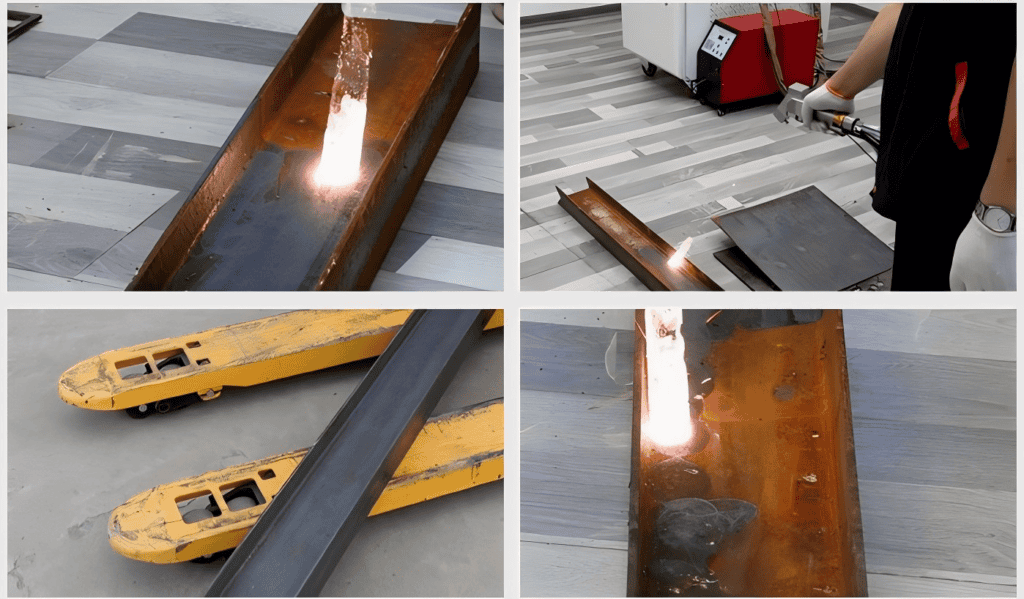

The DG-LW series portable handheld laser welding machine is flexible in design, easy to carry, simple to operate, and can be operated directly without professional welding knowledge. It is suitable for laser welding thin, medium, and thick plates in sheet metal, hardware, building materials, furniture, and other industries, as well as laser welding and spot welding of thick plates. Low price for sale!

The 3-in-1 laser welding machine, cleaner, and cutter is a portable air-cooled integrated laser machine equipped with a handheld laser gun and a 620*585*400mm small cabinet. It occupies a smaller area, is flexible and convenient, and is used for cutting and welding metals and removing rust, paint, and coatings. Now on sale at a low price, welcome to order!

Lithium battery laser welding machine is mainly used for new energy lithium battery pack welding: lithium battery to nickel, explosion-proof valve welding, battery ear welding, battery pole spot welding, battery pole welding, power battery shell and cover sealing welding, large single square shell lithium battery and large polymer power battery module and pack welding, etc. Welcome to buy!

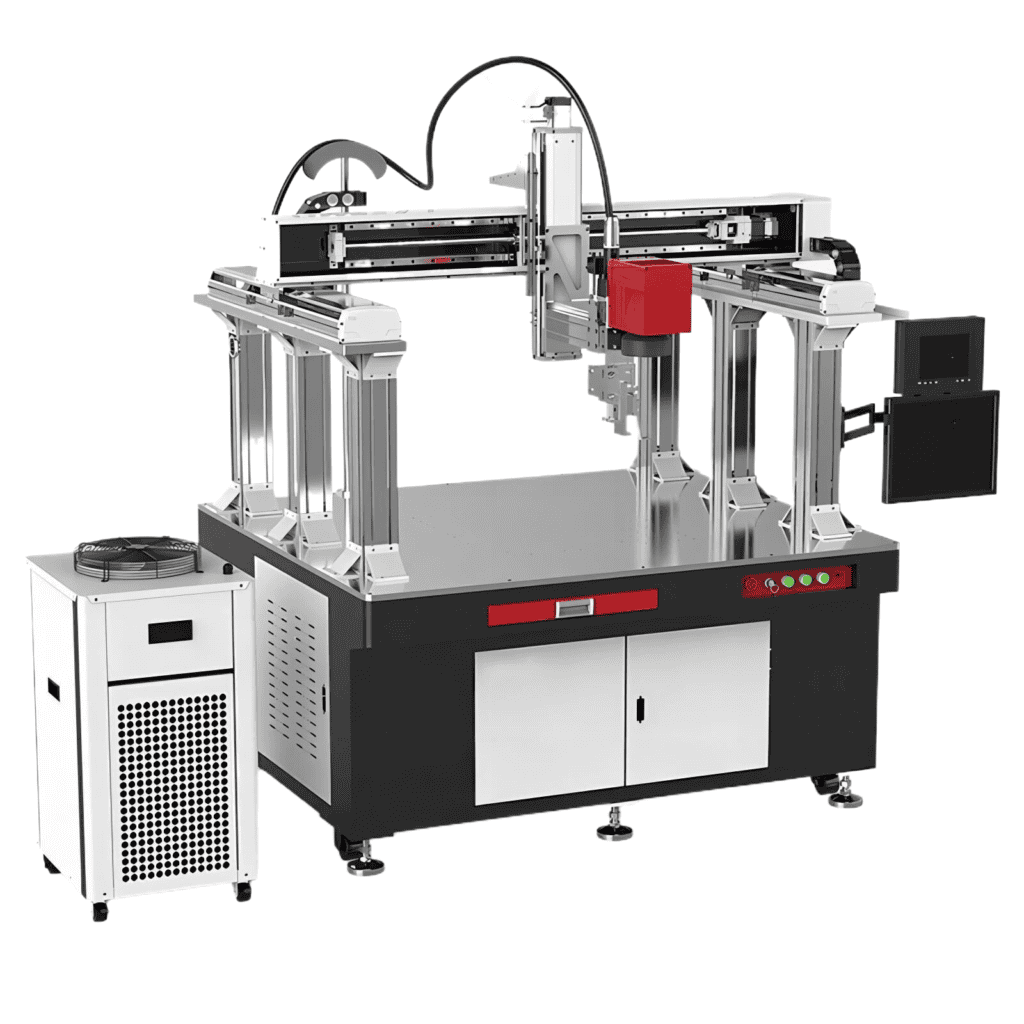

The automatic platform laser welding machine is customizable, detachable, and graftable. It can be quickly connected to the customer’s production line. It has precise positioning, a multi-axis servo welding workbench, and quick response. It can achieve automatic welding without manual movement of the product. It is suitable for a variety of welding materials: stainless steel, carbon steel, galvanized sheet, brass, aluminum alloy sheet and other metals. Welcome to order!

Fully automatic stainless steel strip butt laser welding machine is used for welding galvanized steel rings such as glass cover retaining rings, mesh baskets, trash cans, enamel products, etc. The equipment is mainly composed of laser welding machine, chiller, fully automatic feeding and cutting system, motion control system, manipulator loading and unloading system, and molding system. Now at a promotional price, welcome to customize!

Robotic laser welding machine is suitable for large-area space welding. The robot is intelligent, flexible and reliable. It can operate with six axes and can weld in any space, not limited to plane welding. We have a variety of internationally renowned brand robotic arms (Yaskawa/KUKA/ABB/FANUC…).

Welcome to inquire!

Price: Super good price

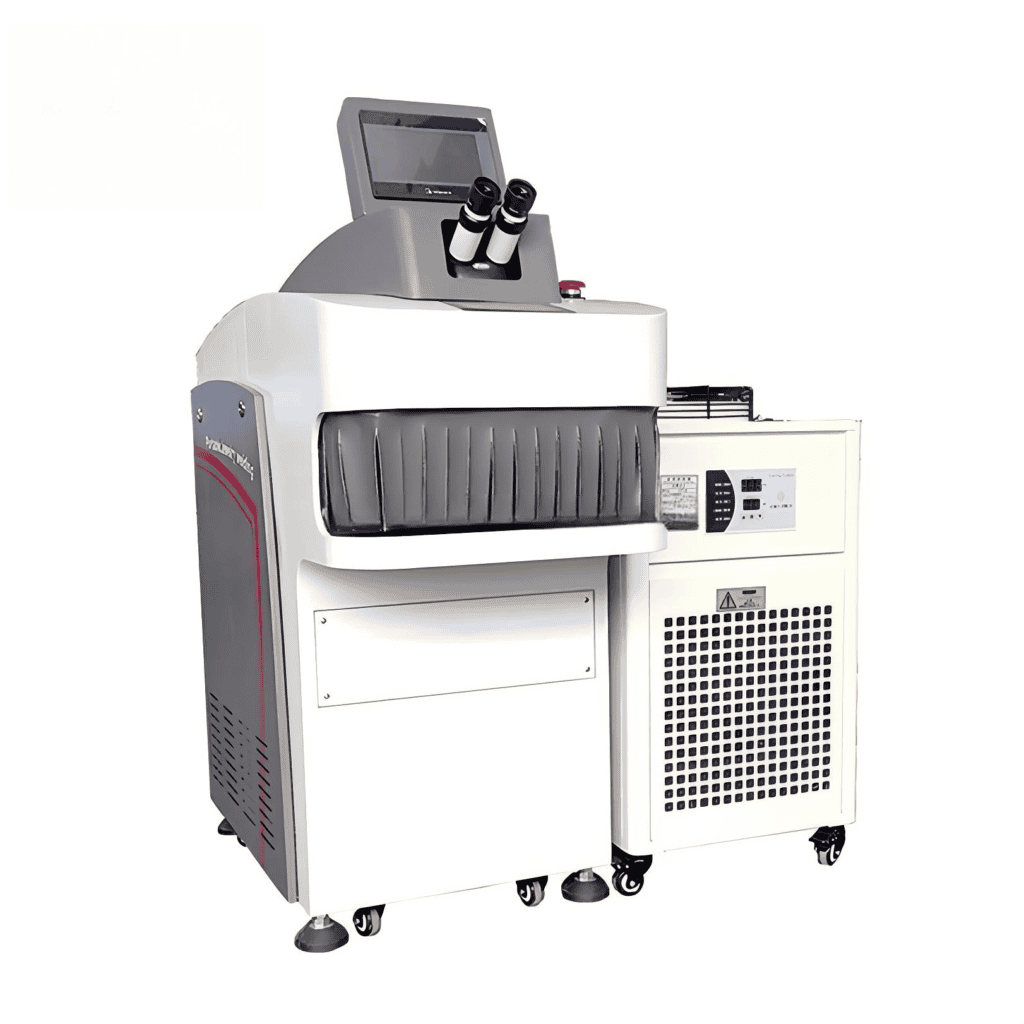

Jewelry laser welding machines are mainly used for welding metals and alloy materials such as gold, silver, platinum, stainless steel, titanium, etc. They can also fill sand holes in dentures and weld tiny devices. After being introduced into the jewelry industry, they have been widely welcomed and widely used for their high speed, high precision and convenience, and have gradually become indispensable and important equipment for jewelry companies. DAGCNC provides a variety of jewelry laser welding machines to meet your various needs and budgets fully. Welcome to buy!

The small jewelry laser spot welding machine is suitable for shopping malls and can be placed directly on the counter. It is small in size, does not take up space, is easy to carry, and is easy to operate. It can be used in jewelry repair shops, watch repair shops, glasses repair shops, dental clinics, electronic repair shops, etc. It is now sold at a promotional price. Welcome to buy!

DAG jewellery laser welder is suitable for welding platinum, K gold, silver, titanium, stainless steel, copper, aluminum, and other metal materials and their alloys. The machine can be customized according to your needs and budget, providing efficient and economical processing solutions. You are welcome to inquire!

QCW laser rope chain machine can produce single, double, and triple cable chains, whip chains, Cuban chains, etc. It can weld stainless steel, K gold, 925 silver, and pure gold chains with diameters of 0.12-0.6mm. The chain made by this machine is faster and more stable than the manual chain. Now, it is sold at a low price; welcome to buy!

The laser welding machine is a welding device that uses a high-energy density laser beam as a heat source. It generates laser light through a laser generator and focuses the laser beam on the part that needs to be welded through the focus and transmission of the optical system. When the laser beam irradiates the surface of the workpiece, the material quickly absorbs the laser energy, reaches the melting point or even vaporizes, thereby achieving the connection of the material.

Laser welding uses high-energy laser pulses to heat a small area of the material locally. The energy of the laser radiation diffuses rapidly into the material’s interior through heat conduction, melting the material to form a specific molten pool for welding and repair.

1. High efficiency: The laser welding machine uses a high-energy-density laser beam as a heat source, which can achieve fast and precise welding. Laser welding is quicker and more efficient than traditional welding methods, which can significantly improve enterprises’ production capacity.

2. High quality: During laser welding, the heat-affected zone is small, the welding deformation is small, the weld is beautiful, and the quality is stable. This makes laser welding the preferred method for many products with high precision and high-quality requirements.

3. High flexibility: The laser welding machine is suitable for welding various metal materials, such as stainless steel, carbon steel, mould steel, copper, aluminium, gold, silver, and others. By adjusting parameters such as laser power and welding speed, welding of different thicknesses and materials can be achieved, which is highly flexible.

4. Energy saving and environmental protection: Laser welding generates less smoke, exhaust gas, and other pollutants, which reduces pollution. At the same time, its relatively low energy consumption helps enterprises achieve the goals of energy saving and emission reduction.

5. Easy to automate: The laser welding machine can be combined with automation equipment such as robots to produce highly automated welding. This can not only improve production efficiency but also reduce dependence on manual labour and improve the stability and reliability of the production line.

6. Strong welding adaptability: Laser welding can accommodate the needs of various complex shapes and structures. It can weld points, lines, circles, tubes, and special-shaped materials, including thin plates, thick plates, pipes, corner welds, and other welding forms.

7. Cost-effectiveness: Although laser welding machines require a high initial investment, their high efficiency, high quality, and long life make them cost-effective in long-term use. In addition, with the advancement of technology and market expansion, the price of laser welding machines is gradually decreasing.

1. Welding

The primary use of laser welding machines is undoubtedly welding. It can weld thin-walled metal materials such as stainless steel plates, aluminium plates, and galvanized plates and be used for sheet metal welding, such as kitchen utensils. It is suitable for welding planes, straight lines, arcs and shapes. It is widely used in precision machinery, jewellery, electronic components, batteries, watches, communications, handicrafts and other industries. It can complete welding well in various complex environments, has high production efficiency, and has more obvious advantages than traditional argon arc welding, electric welding, and other processes.

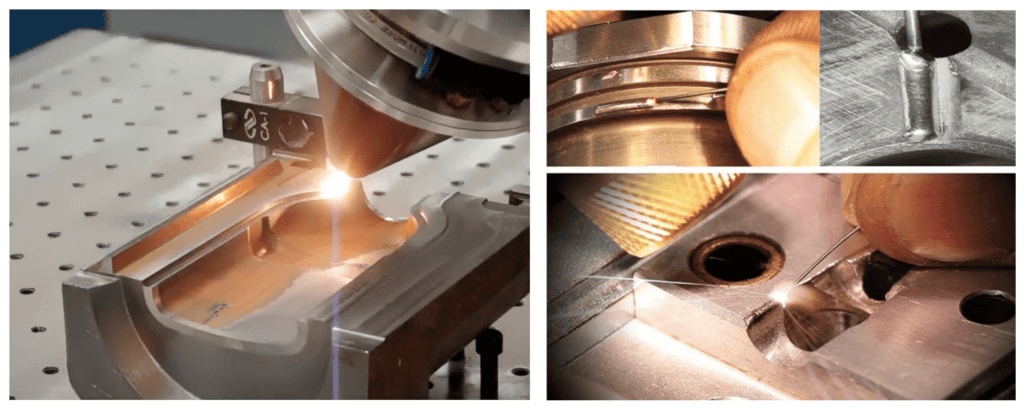

2. Repair

The use of laser welding machines is not limited to welding. It can also repair the wear, defects, scratches of moulds, and defects such as sand holes, cracks, and deformation of metal workpieces. The mould will wear out after a long time of use. If it is directly discarded, the loss will be significant. The mould with problems can be fully utilized again through repair by a laser welding machine, mainly when repairing delicate surfaces, avoiding the two processes of thermal strain and post-weld treatment, significantly saving production time and production costs.

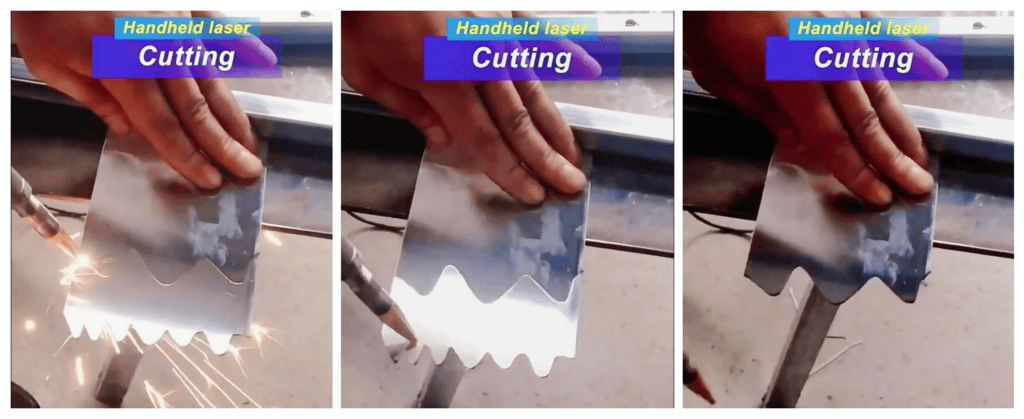

3. Cutting

Laser cutting is a new cutting method. Laser welding machines can cut stainless steel, copper, aluminium, zirconium, and alloys. It is another important application of laser welding machines in material processing.

4. Cleaning

With the continuous reform and upgrading of laser welding machines, their functions are increasing. They can not only weld and cut but also clean and remove rust. Laser welding machines use the beam emitted by the laser to remove the contamination layer on the surface of the workpiece being processed. Using a laser welding machine for cleaning has the characteristics of non-contact, does not require cleaning fluid, and can replace professional cleaning equipment.

Laser welding machines correspond to different powers according to different materials (common welding materials) and can weld different thicknesses, as follows:

Welding of stainless steel materials:

1. 1000 watts of power, can weld 0.5-3 mm;

2. 1500 watts of power, can weld 0.5-5 mm;

3. 2000 watts of power, can weld 6 mm.

Welding of carbon steel materials:

1. 1000 watts of power, can weld 0.5-3 mm;

2. 1500 watts of power, can weld 0.5-5 mm;

3. 2000 watts of power, can weld 6 mm.

Welding of iron materials:

1. 1000 watts of power, can weld 0.5-3 mm;

2. 1500 watts of power, can weld 0.5-5 mm;

3. 2000 watts of power, can weld 6 mm.

Aluminum and its alloy materials:

1. 1000W power, can weld 0.5-2mm;

2. 1500W power, can weld 0.5-3mm;

3. 2000W power, can weld 0.5-5mm.

The thickness of the material that the equipment can weld is closely related to the welding material, material thickness, and welding equipment power. The laser power depends on the thickness of the welding material, which determines the power of the laser equipment.

1. The laser welding machine does not have enough penetration depth. To increase the energy, increase the pulse width and current or reduce the welding speed.

2. Cracks appear during laser welding. The workpiece cools quickly after welding. You can increase the water temperature.

3. Porosity appears during laser welding. The laser welding machine cools quickly, and the pores produced are generally smaller than those produced during traditional fusion welding. You can clean the workpiece surface before welding.

4. The weld is black during laser welding. You can turn on the shielding gas or change the direction of the shielding gas flow.

• Check whether the laser welder’s power supply and water circulation are regular.

• Check whether the gas connection of the machine’s internal equipment is standard.

• Check whether there is dust, spots and oil on the machine’s surface.

Startup steps:

• Turn on the power and turn on the main power switch.

• Turn on the water cooler and generator.

• Open the argon valve and adjust the gas flow.

• Enter the working parameters to be executed.

• Perform welding machine operation.

Shutdown steps:

• Exit the program and turn off the generator.

• Turn off the dust collector, water cooler and other equipment.

• Close the argon cylinder valve.

• Turn off the main power switch.

• During operation, if an emergency (laser leaks water, makes abnormal sounds), press the emergency stop button immediately and cut off the power quickly.

• The external water circulation switch of the welder must be turned on before operation.

• Since the welding system is water-cooled and the power supply is air-cooled, starting the machine when the cooling system fails is strictly forbidden.

• Do not disassemble any parts inside the machine at will, and do not weld with the machine safety door open.

• When the welder is working, it is strictly forbidden to look directly at the laser or reflect the laser with your eyes, and it is strictly forbidden to look directly at the welding gun to avoid eye damage.

• Do not place flammable and explosive items in the optical path or where the beam can be irradiated to avoid fire and explosion.

• When the machine works, the circuit is in a high-voltage, high-current solid state. It is strictly forbidden to touch the internal circuit components of the machine during operation.

• Untrained personnel are prohibited from operating this machine.

When buying a laser welding machine, there are several factors to consider. First, the power and speed of the machine should be regarded as higher power outputs allow for faster and more efficient welding. Second, consider the size and type of material to be welded, and make sure the machine has enough welding capacity to handle the thickness and material of the parts. Accuracy is also essential, as some welding tasks require high precision. Ease of use is another critical factor, as the machine should be simple to set up and operate. Maintenance requirements and costs should also be considered, as machines with low maintenance requirements are more cost-effective in the long run. Price is crucial in the purchasing decision, so it is necessary to set a budget and choose a machine that fits the budget; consider the warranty and customer support provided by the manufacturer to ensure that you can get help if you encounter any problems with the machine. With these factors in mind, you can find a high-quality laser welder that meets your needs and budget. Welcome to consult and order online to establish a long-term partnership!

If you need to buy a CNC metal machine tool, DAG is your first choice. Please send us your detailed requirements and get an instant quote now.

© 2024 Shenzhen DAG Technology Industrial Co., Ltd.All Rights Reserved.

WhatsApp us