Are you looking for a cost-effective laser cleaning machine for rust or paint removal? The laser cleaners provided by DAGCNC can meet these needs. You don’t need to waste time and energy exploring online or offline. We have the most popular types and models of laser cleaning machines on the market, including automatic, portable and handheld series, backpack, suitcase and trolley types. All laser cleaning machines can remove rust, paint, coatings, oxides, plating, oil, stains, dirt, residues and other contamination layers from metal, ceramics, stone, wood and rubber. DAGCNC’s laser cleaning systems are equipped with a variety of power options, including 50W, 100W, 200W and 300W of pulsed fiber laser power and 1000W, 1500W, 2000W and 3000W of continuous (CW) fiber laser power to meet your product surface treatment needs. Whatever you want to do? There is always an option that suits you. Welcome to buy and establish a long-term partnership!

The DG-C1000 continuous laser cleaning machine adopts an integrated design and is easy to move. It can remove rust, paint, oil, surface stains, and electroplating, painting, and welding surface/paint surface pretreatment. You are welcome to inquire!

DG-PC200 pulse laser cleaning machine is a new generation of advanced surface cleaning products. IPad controller supports eight cleaning modes, has manual focus, can switch multiple languages, and can remove resin, oil, stains, dirt, rust, paint, electroplating, paint, etc., on the surface of objects. Welcome to buy!

The 3-in-1 laser welding machine, cleaner and cutter is a portable integrated laser machine equipped with a handheld laser gun, which occupies a small area, is flexible and convenient, and is used for metal cutting, welding, rust removal, paint removal, coating removal and other operations. Welcome to inquire!

DAG portable trolley laser cleaning machine adopts an aviation box design, which is both portable and protective: the equipment can be placed in the trunk of a car or taken to a passenger elevator to achieve mobile operation and can be transported and operated by one person. You are welcome to inquire!

The equipment uses a JPT MOPA fiber laser, and the pulse frequency and width are independently controllable, which can adapt to a broader range of cleaning scenarios. It adopts a suitcase-type design, and the machine weighs only 28kg. It can be transported by high-speed rail and air, with low logistics freight. You are welcome to buy it!

The backpack laser cleaning machine is small in size, light in weight, easy to carry, can be operated by one person, and the operator can move freely. It is suitable for high-altitude operations, outdoor operations, precision moulds and other industries. It is now on sale at a low price, so you are welcome to inquire!

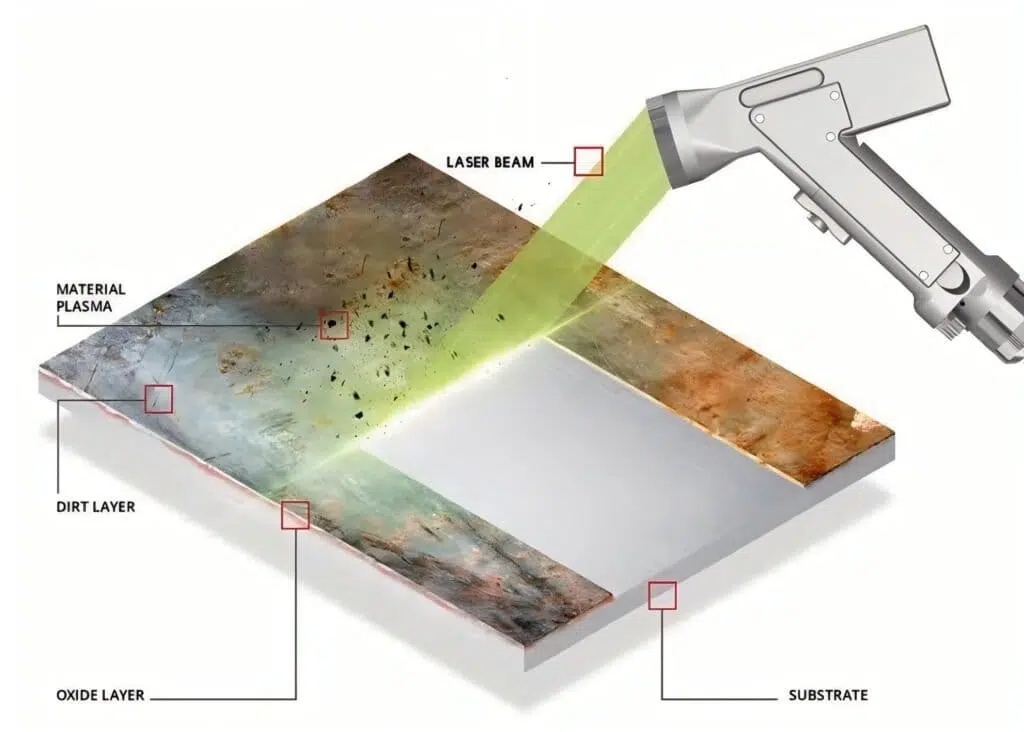

Laser cleaning technology refers to using high-frequency, high-energy laser pulses to irradiate the surface of the workpiece. The coating layer can instantly absorb the focused laser energy, causing the oil, rust or coating on the surface to evaporate or peel off instantly and quickly and effectively remove surface attachments or surface coatings. The laser pulses with very short action time will not damage the metal substrate under appropriate parameters.

The laser cleaning process can be divided into the following steps:

(1) Laser emission: The laser cleaning machine first generates a beam of high-energy laser, usually emitted by a pulsed laser or a continuous wave laser.

(2) Laser focusing: After the optical system focuses the laser beam, it forms a small and energy-intensive light spot, which directly acts on the object’s surface to be cleaned.

(3) Energy transfer: When the laser spot contacts the surface of the object to be cleaned, the energy is quickly transferred to the dirt, causing it to absorb a large amount of heat in a short period of time.

(4) Dirt removal: After the dirt absorbs heat, it quickly heats up and undergoes physical or chemical changes, such as melting, vaporization, cracking, etc., and eventually falls off the object’s surface or is blown away.

(5) Surface cleaning: As the laser beam moves, the dirt on the object’s surface to be cleaned is removed one by one, and the surface is finally cleaned.

A laser cleaning machine is a multi-purpose cleaning equipment. It can clean the surface of metal or non-metal parts. When processing the corresponding workpiece, you only need to adjust the interface parameters of the laser cleaning machine. The laser cleaning machine can clean the following things:

1. Remove the coating on the metal or glass surface and quickly remove the paint;

2. Quickly remove rust and various oxides;

3 Remove grease, resin, glue, dust, stains and production residues;

4 Roughen the metal surface;

5. Paint removal, rust removal, oil removal, oxidation and residue treatment before welding or before bonding;

6 Mold cleanings, such as tyre moulds, electronic moulds, and food moulds;

7. Remove oil stains after the production and processing of precision parts;

8. Rapid cleaning of nuclear power components maintenance;

9. Oxidation treatment, paint removal, and rust removal in the production or maintenance of aerospace weapons and ships;

10. Cleaning of small space metal surfaces.

Laser cleaning plays a vital role in many fields. It is used in automobile manufacturing, semiconductor wafer cleaning, precision parts processing and manufacturing, military equipment cleaning, building exterior wall cleaning, cultural relics protection, circuit board cleaning, precision parts processing and manufacturing, and LCDs. It can play an essential role in cleaning and removing chewing gum residues.

Laser cleaning has the characteristics of no grinding, no contact, and no heat effect and is suitable for objects of various materials. It is considered to be the most reliable and effective solution. At the same time, laser cleaning can solve problems that traditional cleaning methods cannot. Laser cleaning technology has advantages that conventional methods cannot match. With the continuous improvement of technology and the mass production of equipment, laser cleaning technology will play an essential role in the cleaning industry.

Compared with traditional cleaning methods such as mechanical friction cleaning, chemical corrosion cleaning, liquid, solid vigorous impact cleaning, and high-frequency ultrasonic cleaning, laser cleaning has the following six apparent advantages:

1. Green cleaning: No chemical agents are used, and the waste after cleaning is solid, harmless powder, which can completely solve the environmental pollution problem caused by chemical cleaning. Often, an exhaust fan can solve the waste problem generated by cleaning.

2. Non-damage cleaning: Laser cleaning is non-grinding, non-contact, and has no heat effect. It will not produce mechanical force on the cleaned object, damage the surface of the object, damage the substrate, or cause secondary pollution.

3. Low-cost cleaning: The initial investment in the laser cleaning system is high, but it can be used steadily for a long time, with a service life of up to 10 years. It has low operating costs, fast speed, high efficiency, and time savings, and can quickly return on investment. In the long run, the cost is lower than traditional cleaning methods.

4. Convenient advantage: The laser cleaning machine can remove various types of pollutants from the surface of multiple materials, achieving cleanliness that cannot be achieved by conventional cleaning. It can also selectively clean contaminants without damaging the surface of the material.

5. Precision advantage: It can effectively clean micron-level polluted particles and achieve controllable fine cleaning, suitable for cleaning precision instruments and parts.

6. Automated cleaning: Lasers can be transmitted through optical fibers and cooperate with robots to achieve long-distance operation. They can clean complex structural parts that are difficult to reach by traditional methods. This feature also makes the safety of operators in some dangerous places more secure and can be equipped with automated equipment to achieve automated cleaning.

(1) Check whether the appearance of the equipment is intact and ensure that all components are connected tightly.

(2) Check whether the power cord is firmly connected to ensure the equipment is powered typically.

(3) Check to ensure that the cleaning head’s protective mirror is free of dirt.

(4) Turn on the power switch of the equipment and observe whether the equipment is operating normally.

(1) Place the object to be cleaned on the cleaning table and adjust the object’s position so that the laser beam can irradiate the part to be cleaned.

(2) Adjust the laser parameters, including laser power, pulse frequency, etc., through the control panel to meet the cleaning needs of different materials and stains.

(3) Wear goggles, adjust the position of the laser cleaning head to ensure that the laser beam can accurately irradiate the part to be cleaned, press the button on the handle of the handheld head with your finger, and the gun head will light up for cleaning.

(4) pay attention to the cleaning effect and adjust the laser parameters in time during the cleaning process.

(5) After cleaning, turn off the laser cleaning machine, insert the cleaning gun back into the host storage box, unplug the power plug, and remove the cleaned object.

Laser cleaning systems are non-contact, heat-free, and do not generate mechanical force on the surface of the cleaned object. They are widely used in industry. During operation, attention to equipment maintenance and care can increase the service life of the equipment, save costs, and create more significant benefits. The following is an introduction to the maintenance of laser cleaning machines.

(1) Follow the machine switch sequence: turn on the water pump (water cooler), power switch, and laser switch. When shutting down, turn off this switch first, then the power switch, and then the water pump (water cooler).

(2) Clean the chiller regularly every two weeks, drain the dirty water in the machine, and refill it with new pure water (dirty water will affect the light output effect).

(3) Clean regularly and quantitatively daily, remove debris on the workbench, block, and guide rails, and spray lubricating oil on the guide rails.

(4) Wipe the reflector and focusing mirror once every 6-8 hours with a special cleaning fluid. Dip cotton or a cotton swab in the cleaning fluid and wipe counterclockwise from the centre of the focusing mirror to the edge to prevent scratches on the lens.

(1) Avoid laser beam exposure to eyes or skin during cleaning to prevent injury.

(2) Avoid laser beam exposure to flammable and explosive items during cleaning to prevent fire or explosion.

(3) Keep the equipment’s surface dry during cleaning to prevent water or other liquids from entering.

(4) Perform regular maintenance and care on the equipment to ensure normal operation.

The price of a laser cleaning machine depends on different configurations. For example, if a more powerful laser generator is used, the price will be higher, and the cost of a pulsed laser source will be higher than that of a CW (continuous wave) laser source.

Pulsed laser source: A 100W portable laser cleaning machine equipped with a handheld pulsed laser gun costs $7,000, while a 200W pulsed laser beam cleaning machine usually costs $10,000.

CW (continuous wave) laser source: A 1000W portable CW laser cleaning machine costs $4,000. The price range of a 1500W handheld CW laser cleaning machine starts at $4,500. The minimum price of a 2000W high-power laser beam cleaning machine is $6,200. The cost of a 3000W CW laser cleaning gun starts at $8,300. In addition, an automated laser cleaning system equipped with a CNC controller or robot costs up to $18,000.

The best budget 3-in-1 laser welding, cleaning and cutting machine is priced between $4,000 and $9,000, and the fiber laser power options are 1000W, 1500W, 2000W and 3000W.

The above prices are for reference only. In addition to the marked price, customers also need to consider shipping, taxes, customs clearance, and other costs. You are welcome to consult online for specific prices!

If you need to buy a CNC metal machine tool, DAG is your first choice. Please send us your detailed requirements and get an instant quote now.

© 2024 Shenzhen DAG Technology Industrial Co., Ltd.All Rights Reserved.

WhatsApp us