CNC metal laser cutting machine is an automated precision metal cutting system that uses a fiber laser source to emit light and then uses a reflector and focusing mirror to reflect and focus the light onto the laser head. The focused, strong light irradiates the material to be cut, causing it to melt rapidly due to the high temperature, thereby achieving the purpose of cutting. It is a fine cutting tool for cutting metal plates, tubes, rods, and strips, and can cut flat and beveled metal shapes and profiles. It is currently widely used in various metal plate and tube manufacturing and processing industries such as aviation, aerospace, electronics, electrical appliances, subway accessories, automobiles, machinery, precision accessories, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, and advertising. The CNC controller drives the 1064nm laser beam to cut along the tool path generated by the CAD/CAM software, which can obtain clean and smooth metal cuts. The CNC metal laser cutting machine can also be equipped with a robotic arm and can even perform personalized 3D metal cutting. Compared with traditional CNC plasma and water jet cutting machines, CNC metal laser cutting machines have the characteristics of fast speed, high efficiency, good performance, high precision, low cost, easy operation, energy saving and environmental protection, simple maintenance, etc., and are ideal metal cutting tools for modern metal processing. The following are the most popular CNC metal laser cutting machines carefully selected by DAGCNC. From home to commercial use, from hobbies to industrial applications, from entry-level to professional level, you can easily find the machine that best suits your needs and budget; let’s start choosing!

Affordable, top-quality metal laser cutting machines for sheet metal (carbon steel, stainless steel, aluminum, copper, etc.).manufacturing with different laser powers (1000W, 1500W, 2000W, etc.) are now available at low prices. You are welcome to inquire!

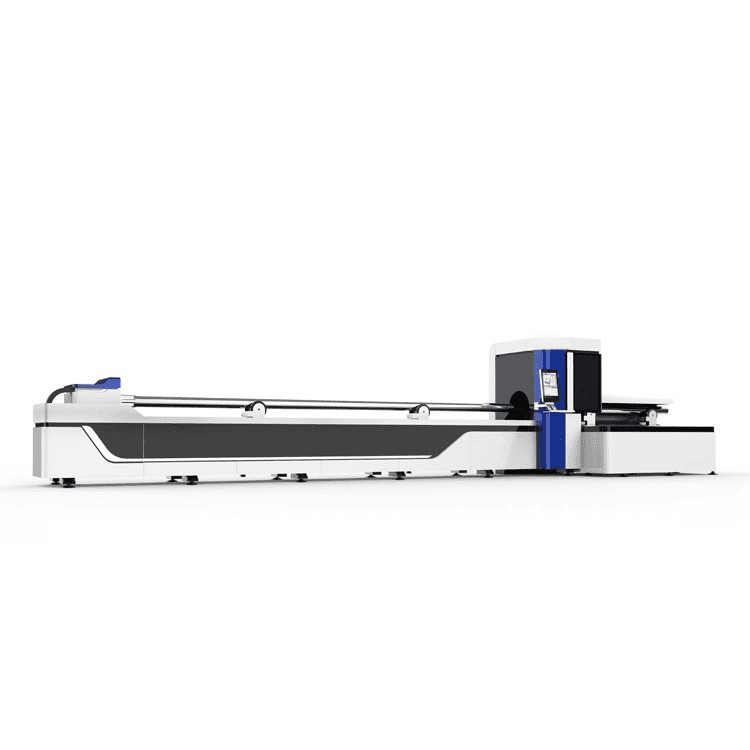

The most popular affordable laser tube cutting machine, equipped with 1000W, 1500W, 2000W, and 3000W fiber laser power options, is an automatic CNC metal tube cutting system. We are now selling the most affordable metal laser tube cutting machine at a low price. Welcome to inquire!

The DG-3015FT laser cutting machine can cut most metal sheets, pipes, and tubes, significantly reducing the cost of purchasing two machines, saving more than 50% of workshop space, and doubling production efficiency. Now, we are selling it at a promotional price. Welcome to order!

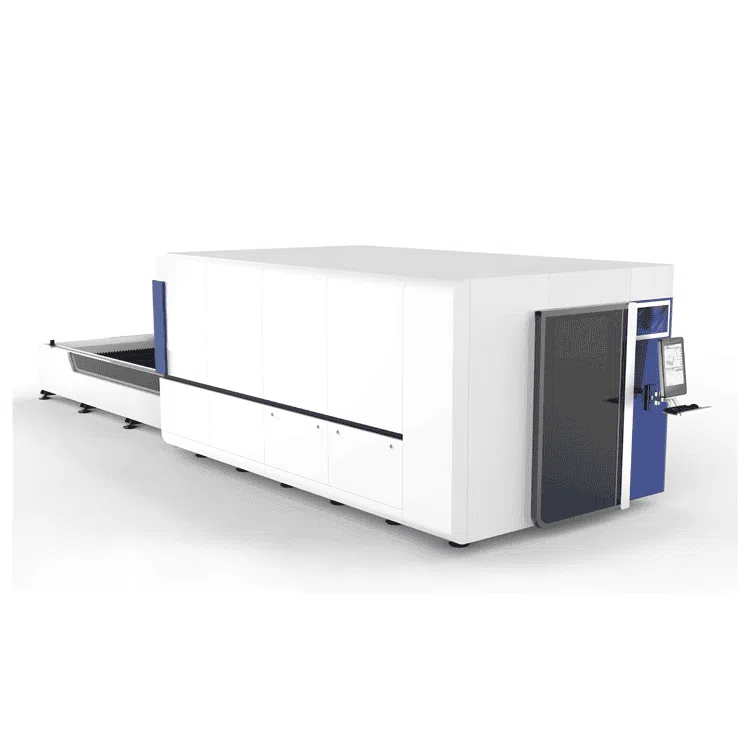

The DG-1530F CNC metal laser cutting machine adopts a dual-table design, with each table working alternately so that one table can cut while the other can load and clean. This mode improves production efficiency while also reducing manual intervention and production costs. Now, we are selling it at a promotional price, and dealers are welcome to inquire!

DG-3015FP CNC metal laser cutting machine adopts a protective cover and double carrier design to reduce mechanical damage, making it safer and more efficient, reducing the spread of sparks and smoke, and being more environmentally friendly. It is your best choice and is now sold at a promotional price. Welcome to order!

Ordinary fiber laser cutting machines cannot accurately process irregular materials, while the 6 robotic arm metal laser cutting machine is suitable for processing workpieces of various shapes, such as automotive sheet metal, 3D kitchenware, sports equipment, etc. It is beneficial in these industries. It is now sold at a low price. Dealers are welcome to inquire!

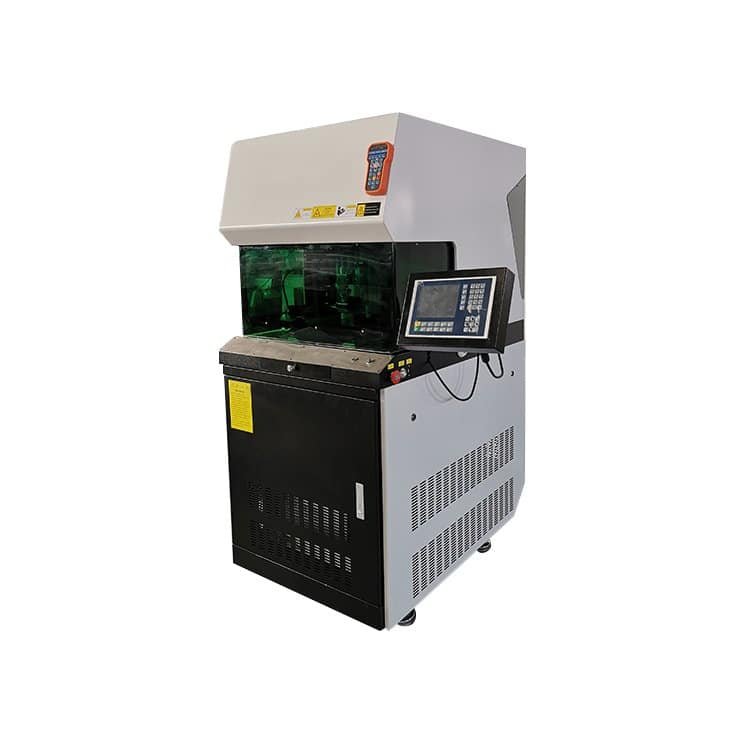

The DG-1390F precision CNC metal laser cutting machine is suitable for small hardware processing plants. Its overall layout is compact and reasonable, and its footprint is small—about 1300*900mm. It is ideal for cutting various metal materials. It is now selling at a hot promotional price. Dealers are welcome to inquire!

Economical and affordable top-grade small precision laser cutting machine, high efficiency, high cutting accuracy (positioning accuracy 0.05mm, repeat positioning accuracy 0.03mm), low cost, safe and stable, easy to operate. Now on sale at the lowest price, welcome to inquire!

The cylindrical materials CNC metal laser cutting machine has optional laser powers of 1000W, 1500W, 2000W… It can cut metal without burrs and has smooth incisions. It is now sold cheaply, so you are welcome to inquire!

Future development trend of CNC metal laser cutting machine

The future development trend and prospects of the CNC metal laser cutting machine industry market are very optimistic. With the transformation and upgrading of the global manufacturing industry and the improvement of automation and intelligence levels, CNC metal laser cutting machines will be used in more fields, and the market size is expected to continue to grow. At the same time, companies must continue to innovate and progress to adapt to market changes and meet customer needs.

CNC metal laser cutting machine is an essential branch of laser cutting. It is a new type of laser equipment that uses a CNC system to control the laser cutting machine. The laser cutting machine uses a high-heat laser to irradiate the metal workpiece’s surface to achieve the workpiece’s cutting. The CNC metal laser cutting machine is a high-tech optomechanical and electrical integrated equipment specially used to cut metal materials. It is the best metal cutting solution for amateurs and industrial manufacturers.

A CNC metal laser cutting machine is an intelligent metal cutting system that works with a CNC controller to drive the fiber laser beam to cut in any direction, angle, bevel and slope according to the designed layout file and create the shape and contour you want.

The high-energy-density laser beam emitted by the laser source instantly evaporates and melts the metal material. The high-pressure gas coaxial with the beam directly removes the molten metal to achieve metal cutting. The core technology is the CNC system that accurately controls the position and intensity of the laser beam, thereby achieving high-precision and high-efficiency cutting.

When laser cutting metal, the laser cutting machine uses the laser tube to emit light and then uses the reflector and focusing mirror to reflect and focus the light onto the laser head. The focused, intense light is emitted to the material to be cut or engraved, causing it to melt rapidly due to the high temperature to achieve the purpose of cutting and engraving. Auxiliary gas suitable for cutting material is also added during the cutting process. When cutting steel, oxygen is used as the auxiliary gas to produce an exothermic chemical reaction with the molten metal to oxidize the material and, at the same time, help blow away the slag in the cutting seam. The auxiliary gas entering the nozzle can also cool the focusing lens to prevent smoke and dust from entering the lens seat to contaminate the lens and cause the lens to overheat.

CNC metal laser cutting machines are widely used in sheet metal processing, advertising sign production, high and low-voltage electrical cabinet production, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, gifts, accessories, saw blades, electrical parts, glasses industry, spring sheets, circuit boards, electric kettles, medical microelectronics, hardware, knife measuring tools and other industries.

They can process stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloy, copper, nickel, galvanized sheet, pickled sheet, titanium, and other metal sheets and tubes. These are suitable for hobbies, home businesses, small shops, commercial use, industrial manufacturing, etc.

Stainless steel

Laser metal cutting machines are an effective cutting tool for manufacturing industries dominated by stainless steel plates. When heat input is strictly controlled, the width of the heat-affected zone of the cutting edge can be limited, thereby ensuring that the stainless steel has good corrosion resistance. Stainless steel laser cutting uses the energy released when the light beam is irradiated on the surface of the steel plate to melt and evaporate the stainless steel. For manufacturing industries dominated by stainless steel plates, laser cutting is a fast and effective method. Critical process parameters that affect the quality of stainless steel cutting include cutting speed, power supply, air pressure, etc.

Carbon steel

The thickness of carbon steel plate laser cutting can reach 70mm. The slit of carbon steel cut by the oxide flux cutting mechanism can be controlled within a satisfactory width range, and the slit of the thin plate can be as narrow as about 0.1mm.

Copper and alloys

Pure copper (red copper) has a too-high reflectivity. Laser cutting of brass (copper alloy) should use higher power, and the auxiliary gas uses air or oxygen to cut thinner plates. Pure copper and brass have high reflectivity and very good thermal conductivity. Pure copper and brass can only be cut when a “reflection absorption” device is installed on the system; otherwise, the reflection will damage the optical components.

Aluminum and alloys

Aluminum plate cutting is easily accomplished with fiber lasers, and fiber lasers have high performance whether cutting aluminum or aluminum alloys.

Nickel and alloys

They are also called high-temperature alloys, and there are many types. Most can obtain good cuts through laser oxidation and flux cutting.

Titanium and alloys

Pure titanium can couple well with the heat energy converted by the focused beam. When oxygen is used as the auxiliary gas, the chemical reaction is violent, and the cutting speed is fast. However, it is easy to form an oxide layer on the cut edge and cause overburning. Therefore, using air as the auxiliary gas can ensure the cutting quality. Laser cutting of titanium alloys is often used in aircraft manufacturing. Titanium plate cutting uses nitrogen and nitrogen as working gases.

Functions

The CNC metal laser cutting machine is fully functional, ranging from a metal sheet cutting machine to a tube cutting machine. It also includes a dual-function 2-in-1 metal sheet and tube cutting system and an all-in-one 6-axis 3D metal laser cutting robot suitable for multiple purposes.

Cutting table

The laser metal cutting table size ranges from small (compact) to large (full size). You can get 300mm x 300mm, 400mm x 600mm, 600mm x 900mm (2×3), 900mm x 1300mm, 1000mm x 1600mm, 1300mm x 2500mm (4×8), 1500mm x 3000mm (5×10), 2000mm x 4000mm (6×12), 2500mm x 6000mm size.

Power

The CNC metal laser cutting machine also has different power options, from 500W to 60000W. Prices range from about $10,000 for low-power cutters to over $1,000,000 for ultra-high-power laser metal cutting machines.

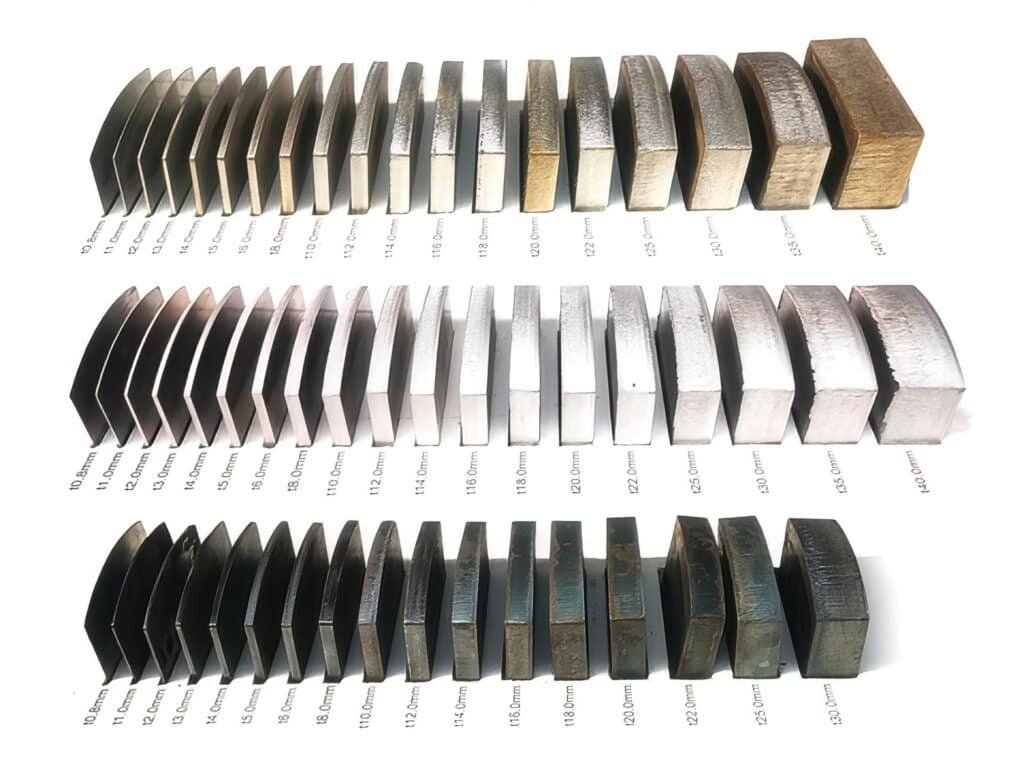

CNC metal laser cutting machines can easily cut various metals of various thicknesses. Fiber laser sources of different powers will produce different maximum metal cutting thicknesses. For the same power, other brands of laser sources also perform differently regarding metal cutting thickness, accuracy, and speed.

Common material cutting thickness comparison table

| Carbon steel | Stainless steel | Aluminum | Brass |

| (1) 500W power: | (1) 500W power: | (1) 500W power: | (1) 500W power: |

| 1mm thickness, cutting speed 8-9m/min; | 1mm thickness, cutting speed 10-12m/min; | 1mm thickness, cutting speed 7-8m/min; | 1mm thickness, cutting speed 5m/min; |

| 2mm thickness, cutting speed 4-5m/min; | 2mm thickness, cutting speed 2m/min; | 2mm thickness, cutting speed 1.5-2m/min; | 2mm thickness, cutting speed 1m/min; |

| 3mm thickness, cutting speed 2m/min; | 3mm thickness, cutting speed 0.7m/min; | (2) 800W power: | (2) 800W power: |

| 4mm thickness, cutting speed 1.5m/min; | (2) 800W power: | 1mm thickness, cutting speed 10m/min; | 1mm thickness, cutting speed 8m/min; |

| 5mm thickness, cutting speed 1.2m/min; | 1mm thickness, cutting speed 16-20m/min; | 2mm thickness, cutting speed 3m/min; | 2mm thickness, cutting speed 2m/min; |

| 6mm thickness, cutting speed 0.9m/min; | 2mm thickness, cutting speed 4.5m/min; | 3mm thickness, cutting speed 0.8m/min; | (3) 1000w power: |

| (2) 800W power: | 3mm thickness, cutting speed 1.7m/min; | (3) 1000W power: | 1mm thickness, cutting speed 10m/min; |

| 1mm thickness, cutting speed 7-10m/min; | (3) 1000W power: | 1mm thickness, cutting speed 12-13m/min; | 2mm thickness, cutting speed 3m/min; |

| 2mm thickness, cutting speed 5-6m/min; | 1mm thickness, cutting speed 20-24m/min n; | 2mm thickness, cutting speed 4-4.5m/min; | 3mm thickness, cutting speed 0.5m/min; |

| 3mm thickness, cutting speed 2-3m/min; | Thickness 2mm, cutting speed 5.4m/min; | 3mm thickness, cutting speed 1-1.5m/min; | (4) 1300w power: |

| 4mm thickness, cutting speed 1.8m/min; | Thickness 3mm, cutting speed 2.2m/min; | (4) 1300W power: | 1mm thickness, cutting speed 11m/min; |

| 5mm thickness, cutting speed 1.5m/min; | Thickness 4mm, cutting speed 1.2m/min; | 1mm thickness, cutting speed 14m/min; | 2mm thickness, cutting speed 4m/min; |

| 6mm thickness, cutting speed 1.3m/min; | (4) 1300W power: | 2mm thickness, cutting speed 5m/min; | 3mm thickness, cutting speed 1.5m/min; |

| 8mm thickness, cutting speed 1m/min; | Thickness 1mm, cutting speed 26-30m/min; | 3mm thickness, cutting speed 2m/min; | 4mm thickness, cutting speed 0.5m/ min; |

| 10mm thickness, cutting speed 0.6m/min n; | Thickness 2mm, cutting speed 6m/min; | 4mm, cutting speed 0.5m/min; | (5) 1500w power: |

| (3) 1000w power: | Thickness 3mm, cutting speed 3.5m/min; | (5) 1500W power: | 1mm thickness, cutting speed 12m/min; |

| Thickness 1mm, cutting speed 9-12m/min; | Thickness 4mm, cutting speed 1.8m/min; | 1mm thickness, cutting speed 15m/min; | 2mm thickness, cutting speed 5m/min; |

| Thickness 2mm, cutting speed 6-8m/min; | Thickness 5mm, cutting speed 0.9m/min; | 2mm thickness, cutting speed 6m/min; | 3mm thickness, cutting speed 2m/min; |

| Thickness 3mm, cutting speed 3m/min; | Thickness 6mm, Cutting speed 0.6m/min; | 3mm thickness, cutting speed 3m/min; | 4mm thickness, cutting speed 0.5m/min; |

| Thickness 4mm, cutting speed 2m/min; | (5) 1500W power: | 4mm thickness, cutting speed 0.8-1m/min; | (6) 2000w power: |

| Thickness 5mm, cutting speed 1.6m/min; | Thickness 1mm, cutting speed 28-32m/min; | (6) 2000W power: | 1mm thickness, cutting speed 15m/min; |

| Thickness 6mm, cutting speed 1.4m/min; | Thickness 2mm, cutting speed 7.5m/min; | 1mm thickness, cutting speed 17-18m/min; | 2mm thickness, cutting speed 6m/min; |

| Thickness 8mm, cutting speed 1.1m/min; | Thickness 3mm, cutting speed 4m/min; | 2mm thickness, cutting speed 7.5m/min; | 3mm thickness, cutting speed 3m/min; |

| Thickness 10mm, cutting speed 0.9m/min; | Thickness 4mm, cutting speed 2m/min; | 3mm thickness, cutting speed 5m/min; | 4mm thickness, cutting speed 1.5m/min; |

| Thickness 12mm, cutting speed 0.7m/min; | Thickness 5mm, cutting speed 1.1m/min; | 4mm thickness, cutting speed 2m/min; | 5mm thickness, cutting speed 0.5m/min; |

| (4) 1300w power: | Thickness 6mm, cutting speed 0.8m/min; | (7) 2500W power: | (7) 2500w power: |

| Thickness 1mm, cutting speed 23-26m/min; | (6) 2000W power: | 1mm thickness, cutting speed 29m/min; | 1mm thickness, cutting speed 24m/min; |

| Thickness 2mm, cutting speed 7-9m/min; | Thickness 1mm, cutting speed 38m/min; | 2mm thickness, cutting speed 8.5m/min; | 2mm thickness, cutting speed 7.5m/min; |

| Thickness 3mm, cutting speed 3m/min; | Thickness 2mm, Cutting speed 12m/min; | 3mm thickness, cutting speed 5m/min; | 3 mm, cutting speed 4m/min; |

| Thickness 4mm, cutting speed 2.5m/min; | Thickness 3mm, cutting speed 7m/min; | 4mm thickness, cutting Speed 3m/min; | Thickness 4mm, cutting speed 2m/min; |

| Thickness 5mm, cutting speed 2m/min; | Thickness 4mm, cutting speed 4m/min; | Thickness 5mm, cutting speed 1m/min; | Thickness 5mm, cutting speed 1m/min; |

| Thickness 6mm, cutting speed 1.6m/min; | Thickness 5mm, cutting speed 2m/min; | Thickness 6mm, cutting speed 0.6m/min; | Thickness 6mm, cutting speed 0.5m/min; |

| Thickness 8mm, cutting speed 1.2m/min; | Thickness 6mm, cutting speed 1.5m/min; | (8) 3000W power: | (8) 3000w power: |

| Thickness 10mm, cutting speed 1m/min; | Thickness 8mm, cutting speed 0.8m/min; | Thickness 1mm, cutting speed 45m/min; | Thickness 1mm, cutting speed 40m/min; |

| Thickness 12mm, cutting speed 0.9m/min; | Thickness 10mm, cutting speed 0.5m/min; | Thickness 2mm, cutting speed 11m/min; | Thickness 2mm, cutting speed 10m/min; |

| Thickness 14mm, cutting speed 0.6m/min; | (7) 2500W power: | Thickness 3mm, cutting speed 7m/min; | Thickness 3mm, cutting speed 4m/min; |

| Thickness 16mm, cutting speed 0.5m/min; | Thickness 1mm, cutting speed 30m/min; | Thickness 4mm, cutting speed 4m/min; | Thickness 4mm, cutting speed 3m/min; |

| (5) 1500w power: | Thickness 2mm, cutting speed 10m/min; | Thickness 5mm, cutting speed 1.5m/min; | Thickness 5mm, cutting speed 1.5m/min; |

| Thickness 1mm, cutting speed 27-30m/min; | Thickness 3m m, cutting speed 6m/min; | Thickness 6mm, cutting speed 1m/min; | Thickness 6mm, cutting speed 0.8m/min; |

| Thickness 2mm, cutting speed 8-10m/min; | Thickness 4mm, cutting speed 4m/min; | Thickness 8mm, cutting speed 0.5m/min; | (9) 4000w power: |

| Thickness 3mm, cutting speed 3m/min; | Thickness 5mm, cutting speed 2.5m/min; | (9) 4000W power: | Thickness 1mm, cutting speed 30-33m/min; |

| Thickness 4mm, cutting speed 2.5m/min; | Thickness 6mm, cutting speed 1.5m/min; | Thickness 1mm, cutting speed 35-37m/min; | Thickness 2mm, cutting speed 13m/min; |

| Thickness 5mm, cutting speed 2m/min; | Thickness 8mm, cutting speed 0.7m/min; | Thickness 2mm, cutting speed 15m/min; | Thickness 3mm, cutting speed 7m/min; |

| Thickness 6mm, cutting speed 1.8m/min; | Thickness 10mm, cutting speed 0.5m/min; | Thickness 3mm, cutting speed 8-9m/min; | Thickness 4mm, cutting speed 5m/min; |

| Thickness 8mm, cutting speed 1.3m/min; | (8) 3000W power: | Thickness 4mm, cutting speed 6m/min; | Thickness 5mm, cutting speed 2m/min; |

| Thickness 10mm, cutting speed 1.1m/min; | Thickness 1mm, cutting speed 50m/min; | Thickness 5mm, cutting speed 3m/min; | Thickness 6mm, cutting speed 1.5m/min; |

| Thickness 12mm, cutting Cutting speed 0.9m/min; | Thickness 2mm, cutting speed 13m/min; | Thickness 6mm, cutting speed 2m/min; | Thickness 8mm, cutting speed 0.8m/min; |

| Thickness 14mm, cutting speed 0.6m/min; | Thickness 3mm, cutting speed 8m/min; | Thickness 8mm, cutting speed 1m/min; | (10) 6000w power: |

| Thickness 16mm, cutting speed 0.5m/min; | Thickness 4mm, cutting speed 5m/min; | Thickness 10mm, cutting speed 0.5m/min; | Thickness 1mm, cutting speed 65-70m/min; |

| (6) 2000w power: | Thickness 5mm, cutting speed 2.5m/min; | (10) 6000W power: | Thickness 2mm, cutting speed 20-25m/min; |

| Thickness 1mm, cutting speed 27-30m/min; | Thickness 6mm, cutting speed 1.5m/min; | Thickness 1mm, cutting speed 70-75m/min; | Thickness 3mm, cutting speed 5m/min; |

| Thickness 2mm, cutting speed 10-12m/min; | Thickness 8mm, cutting speed 1m/min; | Thickness 2mm, cutting speed 25-30m/min; | Thickness 4mm, cutting speed 4m/min; |

| Thickness 3mm, cutting speed 3m/min; | Thickness 10mm, cutting speed 0.8m/min; | Thickness 3mm, cutting speed 15m/min; | Thickness 5mm, cutting speed 3m/min; |

| Thickness 4mm, cutting speed 3.1m/min; | Thickness 12mm, cutting speed 0.5m/min; | Thickness 4mm, cutting speed 10m/min; | Thickness 6mm, cutting speed 2m/min; |

| Thickness 5mm, cutting speed 2.5-3m/min; | (9) 4000W power: | Thickness 5mm, cutting speed 8m/min; | Thickness 8mm, cutting speed 1.2m/min; |

| Thickness 6mm, cutting speed 2.2m/min; | Thickness 1mm, cutting speed 42-43m/min; | Thickness 6mm, cutting speed 5.5m/min; | Thickness 10mm, cutting speed 0.8m/min. |

| Thickness 8mm, cutting speed 1.5m/min; | Thickness 2mm, cutting speed 19-20m/min; | Thickness 8mm, cutting speed 2.5m/min; | |

| Thickness 10mm, cutting speed 1m/min; | Thickness 3mm, cutting speed 11-12m/min; | Thickness 10mm, cutting speed 1.3m/min; | |

| Thickness 12mm, cutting speed 0.8m/min; | Thickness 4mm, cutting speed 6.5-7.5m/min; | Thickness 12mm, cutting speed 0.9m/min; | |

| Thickness 14mm, cutting speed 0.7m/min; | Thickness 5mm, cutting speed 4-5m/min; | ||

| Thickness 16mm, cutting speed 0.6m/min; | Thickness 6mm, cutting speed 2-3m/min; | ||

| Thickness 18mm, cutting speed 0 .5m/min; | Thickness 8mm, cutting speed 1.5-2m/min; | ||

| Thickness 20mm, cutting speed 0.4m/min; | Thickness 10mm, cutting speed 1m/min; | ||

| (7) 2500w power: | Thickness 12mm, cutting speed 0.8m/min; | ||

| Thickness 1mm, cutting speed 30m/min; | (10) 6000W power: | ||

| Thickness 2mm, cutting speed 12m/min; | Thickness 1mm, cutting speed 70-75m/min; | ||

| Thickness 3mm, cutting speed 4m/min; | Thickness 2mm, cutting speed 25-30m/min; | ||

| Thickness 4mm, cutting speed 3.3m/min; | Thickness 3mm, cutting speed 12-15m/min; | ||

| Thickness 5mm, cutting speed 2.5m/min; | Thickness 4mm, cutting speed 7.5-9m/min; | ||

| Thickness 6mm, cutting speed 2.3m/min; | Thickness 5mm, cutting speed 6-7.5m/min; | ||

| Thickness 8mm, cutting speed 1.5m/min; | Thickness 6mm, cutting speed 5-6.5m/min; | ||

| Thickness 10mm, cutting speed 1.2m/min; | Thickness 8mm, cutting speed 3.5-4.5m/min; | ||

| Thickness 12mm, cutting speed 1m/min; | Thickness 10mm, cutting speed 2.1m/min; | ||

| Thickness 14mm, cutting speed 0.8m/min; | Thickness 12mm, cutting speed 1.1m/min; | ||

| Thickness 16mm, cutting speed 0.7m/min; | Thickness 14mm, cutting speed 0.9m/min; | ||

| Thickness 18mm, cutting speed 0.6m/min; | |||

| Thickness 20mm, cutting speed 0.5m/min; | |||

| Thickness 22mm, cutting speed 0.4m/min; | |||

| (8) 3000w power: | |||

| 1mm thickness, cutting speed 50m/min; | |||

| 2mm thickness, cutting speed 13m/min; | |||

| 3mm thickness, cutting speed 4.5m/min; | |||

| 4mm thickness, cutting speed 3.5m/min; | |||

| 5mm thickness, cutting speed 3m/min; | |||

| 6mm thickness, cutting speed 2.5m/min; | |||

| 8mm thickness, cutting speed 2m/min; | |||

| 10mm thickness, cutting speed 1.4m/min; | |||

| 12mm thickness, cutting speed 1.1m/min; | |||

| 14mm thickness, cutting speed 0.9m/min; | |||

| 16mm thickness, cutting speed 0.8m/min; | |||

| 18mm thickness, cutting speed 0.7m/min; | |||

| 20mm thickness, cutting speed 0.6m/min; | |||

| 22mm thickness, cutting speed 0. 5m/min; | |||

| (9) 4000w power: | |||

| Thickness 1mm, cutting speed 43m/min; | |||

| Thickness 2mm, cutting speed 20m/min; | |||

| Thickness 3mm, cutting speed 4.5m/min; | |||

| Thickness 4mm, cutting speed 3.8m/min; | |||

| Thickness 5mm, cutting speed 3.5m/min; | |||

| Thickness 6mm, cutting speed 2.8m/min; | |||

| Thickness 8mm, cutting speed 2.3m/min; | |||

| Thickness 10mm, cutting speed 1.8m/min; | |||

| Thickness 12mm, cutting speed 1.5m/min; | |||

| Thickness 14mm, cutting speed 1m/min; | |||

| Thickness 16mm, cutting speed 0.9m/min; | |||

| Thickness 18mm, cutting speed 0.8m/min; | |||

| Thickness 20mm, cutting speed 0.7m/min; | |||

| Thickness 22mm, cutting speed 0.5m/min; | |||

| (10) 6000w power: | |||

| Thickness 1mm, cutting speed 70-75m/min; | |||

| Thickness 2mm, cutting speed 25-30m/min; | |||

| Thickness 3mm, cutting speed 4.5m/min; | |||

| Thickness 4mm, cutting speed 3.8m/min; | |||

| Thickness 5mm, cutting speed 3.7m/min; | |||

| Thickness 6mm, cutting speed 3.3m/min; | |||

| Thickness 8mm, cutting speed 2.8m/min; | |||

| Thickness 10mm, cutting speed 2.1m/min; | |||

| Thickness 12mm, cutting speed 1.6m/min; | |||

| Thickness 14mm, cutting speed 0.95m/min; | |||

| Thickness 16mm, cutting speed 0.85m/min; | |||

| Thickness 18mm, cutting speed 0.75m/min; | |||

| Thickness 20mm, cutting speed 0.65m/min; | |||

| Thickness 22mm, cutting speed 0.5m/min; |

Pre-operation inspection

The central controller housing, power supply housing, switch power supply housing, motor driver housing, data cable housing, machine tool rail, motor housing, exhaust fan housing, and main grounding point are well connected. Poor grounding will shorten the service life, and high-voltage discharge will damage the control circuit and threaten life safety.

Precautions

1. Comply with the general cutting machine safety operating procedures and start the laser cutting machine in strict accordance with the laser startup procedure;

2. The laser cutting machine operator should undergo professional training and be familiar with the structure, performance, operation process and control panel of the equipment;

3. Wear the protective equipment required for operating the machine as needed. When operating, avoid laser damage to the eyes and wear protective glasses;

4. Some materials need to be handled with caution. Do not process them at will before clarifying whether laser cutting machines can produce certain materials to avoid toxic fumes and potential dangers;

5. When the equipment works, the operator shall not leave the work without authorization. If the machine is not in working position or entrusted to someone to look after, the power should be turned off, or the machine should be shut down;

6. Fire extinguishing facilities should be placed within reach, and the laser or shutter should be turned off after processing;

7. Do not place flammable items such as paper and cloth around the machine studio to prevent fire;

8. Operators are required to have the ability to respond. If any abnormal situation occurs during processing, the machine should be shut down immediately, and the fault should be eliminated or repaired in time;

9. Before and after the use of the laser cutting machine, the equipment should be checked to ensure the safety and specifications of the surrounding environment and the machine itself so that the machine can work efficiently;

10. avoid crushing welding wires and causing leakage when using gas cylinders. The use and transportation of gas cylinders should comply with the gas cylinder monitoring regulations. Gas cylinders should be kept away from direct sunlight and fire sources. When activated, the operator should stand on the side of the nozzle to avoid accidents;

11. When repairing the equipment, the high-voltage safety regulations should be strictly followed;

12. After starting up, the machine tool should be manually started at low speed in the X and Y directions to check whether the equipment is abnormal;

13. After inputting the new workpiece program, a trial run should be performed, and its operation should be checked;

14. When the equipment is working, attention should be paid to its stability, and the machine should be checked in advance to see if it is fixed to avoid slippage and collision.

★★★ It is forbidden to use the machine in the following situations.

The machine shall not be turned on in severe weather like thunderstorms.

Untrained operators shall not operate the machine alone.

Regular maintenance is also essential to make the metal laser cutting machine reach a better operating state. Pay attention to the following points during maintenance:

• Daily cleaning is required to keep it clean and tidy.

• After the machine tool stops working, check whether the X, Y, and Z axes can return to the origin. If not, check whether the origin switch position is offset.

• The slag removal drag chain needs to be cleaned every day.

• Clean the adhesive on the air outlet filter in time to ensure the smooth flow of the ventilation duct.

• Clean the cutting nozzle once every 1 hour of operation and replace it every 2-3 months.

• Clean the focusing lens to keep its surface residue-free and replace it every 2-3 months.

• Check the temperature of the cooling water. The generator’s water inlet temperature should be between 19°C and 22°C.

• Clean the dust on the heat sink of the water cooler and freeze dryer. To ensure the heat dissipation efficiency, dust must be removed.

• Frequently check the voltage regulator’s working status and monitor whether the input and output voltages are normal.

• Monitor and check whether the switch of the mechanical shutter is standard.

• The auxiliary gas is a high-pressure gas. Please pay attention to the surrounding environment and personal safety when using it.

• Switching order:

Start

If conditions permit, bake the open-air, water-cooled unit, cold dryer, air compressor, main engine, and generator for 10 minutes.

Shutdown

First, press high pressure, then low pressure, and turn off the generator after the turbine stops rotating silently. Then, turn off the water-cooled unit, air compressor, gas unit, and cold dryer, and turn off the machine’s power. Finally, turn off the voltage stabilizer.

1. Eye damage: The intense light generated by the laser cutting machine harms the eyes. If you look directly at the laser cutting equipment for a long time or even briefly at the high-intensity beam, it may cause eye damage, and in severe cases, it may even cause blindness.

2. Skin damage: The laser beam of the laser cutting machine can also cause damage to the skin. Long-term contact can cause dry skin, ageing, pigmentation, burns, etc.

3. Respiratory damage: The high temperature generated by the laser is combined with gas to complete various processing, and a large amount of dust will also be generated. Especially when processing some special metal materials, the dust generated contains chemical components that can harm the human body if inhaled.

To avoid the above hazards, the following protective measures need to be taken:

1. Wear goggles: You must wear special goggles when using a metal laser cutting machine. Goggles can effectively protect the eyes from the harm of solid beams.

2. Wear protective clothing: The operator should wear anti-radiation protective clothing to protect the skin from damage by the laser beam.

3. Wear a mask: When operating a metal laser cutting machine, pay attention to respiratory protection, install a matching dust removal device, try to operate in an environment with unobstructed air, and wear a mask.

4. Keep a distance: When operating a metal laser cutting machine, it is strictly forbidden to put your arms or head into the cutting machine, and you must keep a safe distance from the equipment. For safety reasons, it is recommended that operators wear long-sleeved clothes to prevent skin burns caused by direct laser irradiation and prevent slag from splashing on the skin and causing burns. Do not touch the cutting part immediately, and wear gloves to avoid residual heat burns.

5. Train operators: To ensure the safety of the equipment, a designated person should be selected to operate it and fully trained to better protect the users.

In short, laser cutting machines have become indispensable equipment in modern industrial production, but safety issues cannot be ignored. Users can only roughly improve their work efficiency and user experience while ensuring safety.

CNC metal laser cutting machine has the following advantages:

1. High speed, high efficiency and high performance.

2. High precision, low cost and simple operation.

3. Wide range of processing materials, advanced technology, and muscular flexibility.

4. Energy saving and environmental protection, simple maintenance.

5. High technology, high reliability and integrated design of electrical cabinet.

6. High-cost performance and standardized after-sales service.

7. High-end atmosphere, beautiful and practical, safety protection design.

8. An imported servo motor and guide bed transmission mechanism are adopted, with small thermal deformation and high transmission accuracy.

9. Wide range of applications and low operating cost.

10. Clean, safe and pollution-free.

11. Fast cutting speed, narrow slit, smooth cutting surface and low material consumption.

12. High-end imported software, simple operation, safe and stable performance.

13. The optical path system and control system are reliable and stable.

14. Reasonable architecture, leading technology, superior performance, high-speed operation and perfect functions.

15. Reasonable structure, convenient operation, stable laser operation and low maintenance cost.

16. Easy to use: You can operate it efficiently whether you are a beginner or a professional, young or old.

After browsing and researching, you can complete most online shopping by following the eight steps below. Let us guide you through every step of the buying process.

Step 1. Request a consultation.

You can consult our sales manager online. After we understand your needs, we will recommend the most suitable CNC metal laser cutting machine to you.

Step 2. Get a free quote.

We will provide a detailed quote based on the CNC metal laser cutting machine you inquired about. You will get the best machine specifications and affordable prices within your budget.

Step 3. Sign a contract.

Both parties carefully evaluate and discuss all order details (technical parameters, specifications, and commercial terms) to eliminate misunderstandings. If you have no questions, we will send you a PI (Proforma Invoice) and sign a contract.

Step 4: Build your machine.

We will arrange the CNC metal laser cutting machine manufacturing as soon as we receive your signed sales contract and deposit. Buyers will be updated with the latest news on the manufacturing progress.

Step 5. Inspection.

The entire production process is subject to regular inspections and strict quality control. The machine is inspected before leaving the factory to ensure it works properly.

Step 6. Shipping.

After confirmation, shipment will start according to the contract’s terms. You can ask for shipping information at any time.

Step 7. Customs clearance.

We will provide and deliver all necessary shipping documents to the buyer and ensure smooth customs clearance.

Step 8. Support and service.

We will provide professional technical support and free customer service via phone, email, Skype, WhatsApp, online live chat, and remote service. In some areas, we also offer door-to-door delivery for all types of CNC metal laser cutting machines.

If you need to buy a CNC metal machine tool, DAG is your first choice. Please send us your detailed requirements and get an instant quote now.

© 2024 Shenzhen DAG Technology Industrial Co., Ltd.All Rights Reserved.

WhatsApp us