MAX Fiber Laser Source For Sale

CW Fiber Laser Source

Product Description

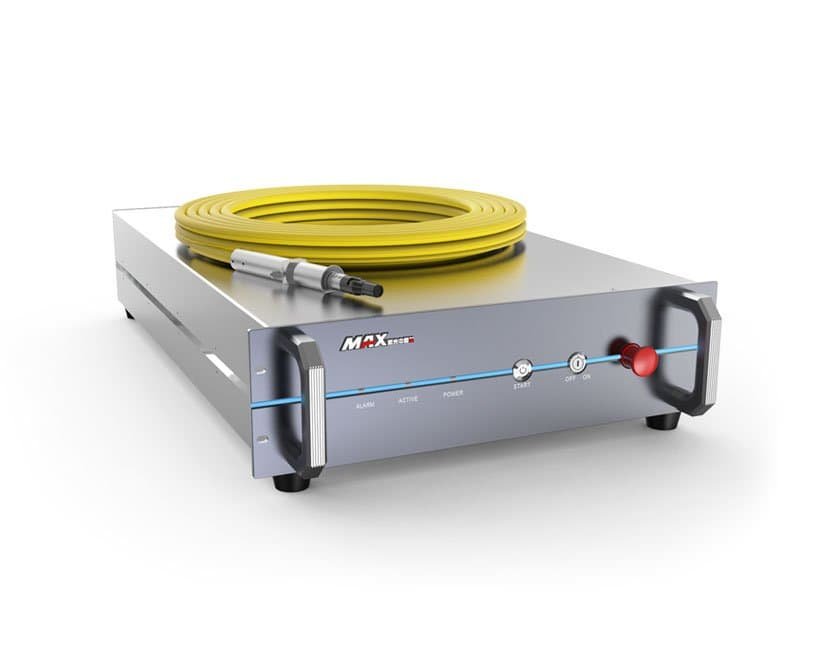

MFSC-300W

| Model | MFSC-300W |

| OPTICAL SPECIFICATIONS | |

| Nominal Power | 300W |

| Mode of Operation | CW/Modulated |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 1080 ± 10 nm |

| Power Stability | ±1 % |

| Laser Beam Quality M² | 1.1~1.2 |

| Modulation Frequency | 20~50kHz |

| Preview Red Light Power | 150μW |

| FIBER DELIVERY SYSTEM | |

| Interface | QCS/QBH(LOC) |

| Length | 2m standard, other lengths optional |

| Diameter | 20(25/30/50) μm |

| Bending Radius | 200 mm |

| ELECTRICAL RATINGS | |

| Supply Voltage | 220VAC (-15% to +10%) Single-phase |

| OTHER SPECIFICATIONS | |

| Operating Temperature | 0 to +35℃ |

| Storage Temperature | -10 to +60℃ |

| Humidity | 10 to 90% |

| Cooling Method | Air Cooling |

| Dimension | 482×610.4×139.3 mm |

| Weight | 26 kg |

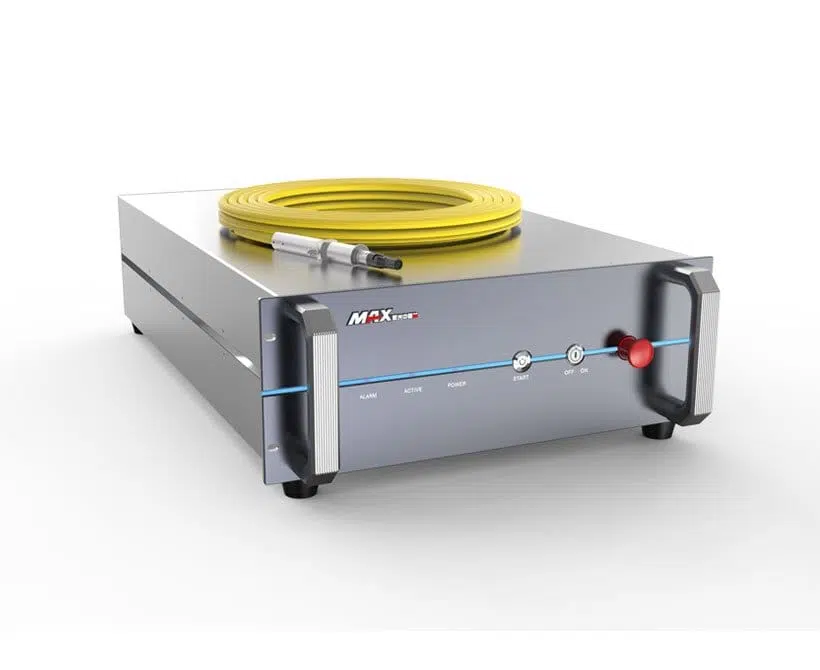

MFSC-500W

| Model | MFSC-500W |

| OPTICAL SPECIFICATIONS | |

| Nominal Power | 500W |

| Mode of Operation | CW/Modulated |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 1080 ± 10 nm |

| Power Stability | ±1 % |

| Laser Beam Quality M² | 1.3(20u QBH) 1.8(50u QBH) |

| Modulation Frequency | ≤20 kHz |

| Preview Red Light Power | 150 μW |

| FIBER DELIVERY SYSTEM | |

| Interface | QBH |

| Length | 10m standard, other lengths optional |

| Diameter | 50(14/20/25/30/100) μm |

| Bending Radius | 200 mm |

| ELECTRICAL RATINGS | |

| Supply Voltage | 220VAC (-15% to +10%) Single-phase |

| OTHER SPECIFICATIONS | |

| Operating Temperature | +10 to +40℃ |

| Storage Temperature | -10 to +60℃ |

| Humidity | 10 to 85% |

| Cooling Method | Water Cooling |

| Cooling Medium | Distilled water/ Glycol Antifreeze |

| Dimension | 725.9×482.6×154.7 mm |

| Weight | 35(±2) kg |

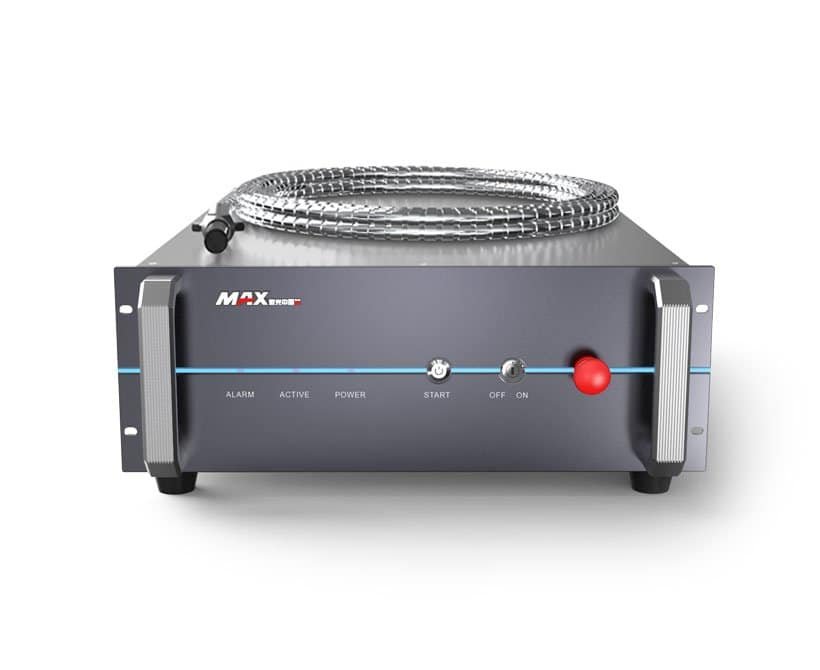

MFSC 1000W-6000W

The MFSC 1000W-6000W SINGLE MODULE CW FIBER LASER stands out as a high-power fiber laser known for its high electro-optical conversion efficiency, compactness, superior beam quality, and maintenance-free feature. It offers a broad spectrum of fiber core diameter, starting from 100~600um, which can be customized further from 800um~1000um. This product finds its significant applications in metal welding, cladding, new energy, 3C, precision machining, and many more.

Application Benefits:

Up to 6KW Output From CW Single Module Series with impeccable beam quality.

Highly efficient, coupled with a reduction in volume, facilitates easy system integration.

Compact, maintenance-free design ensures a minimized Total Cost of Ownership (TCO).

In-house production of pivotal components guarantees quality and reliability.

Industry Applications:

Telecommunication: Marking on communication jumpers, cables, optical cables.

Sheet Metal Processing: Tasks involving steel plate and tube cutting/welding.

Construction: Laser applications on iron frames.

Shipbuilding, Home Appliance Manufacturing, Petrochemical Industry, Advertising, 3C Consumer Electronics, Scientific Research, Aerospace, Photovoltaic Industry, Packing Industry, Clocks, and Watches.

| Models | MFSC-1000W | MFSC-1500W | MFSC-2000W | MFSC-3000W | MFSC-4000W | MFSC-5000W | MFSC-6000W |

| OPTICAL SPECIFICATIONS | |||||||

| Nominal Power | 1000W | 1500W | 2000W | 3000W | 4000W | 5000W | 6000W |

| Mode of Operation | CW/Modulated | CW/Modulated | CW/Modulated | CW/Modulated | CW/Modulated | CW/Modulated | CW/Modulated |

| Polarization | Random | Random | Random | Random | Random | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% |

| Wavelength | 1080 ± 10 nm | 1080 ± 10 nm | 1080 ± 10 nm | 1080 ± 10 nm | 1080 ± 10 nm | 1080 ± 10 nm | 1080 ± 10 nm |

| Power Stability | ±1 % | ±1 % | ±1 % | ±1 % | ±1 % | ±1 % | ±1 % |

| Laser Beam Quality, BPP | 3.1 to 3.5 mm x mrad (100μmQBH) | 3.1 to 3.5 mm x mrad (100μmQBH) | 3.1 to 3.5 mm x mrad (100μmQBH) | 3.1 to 3.5 mm x mrad (100μmQBH) | 3.1 to 3.5 mm x mrad (100μmQBH) | 3.1 to 3.5 mm x mrad (100μmQBH) | 3.1 to 3.5 mm x mrad (100μmQBH) |

| 6.4 to 7 mm x mrad (200μmQBH) | 6.4 to 7 mm x mrad (200μmQBH) | 6.4 to 7 mm x mrad (200μmQBH) | 6.4 to 7 mm x mrad (200μmQBH) | 6.4 to 7 mm x mrad (200μmQBH) | 6.4 to 7 mm x mrad (200μmQBH) | 6.4 to 7 mm x mrad (200μmQBH) | |

| 10 to 12 mm x mrad (300μmQBH) | 10 to 12 mm x mrad (300μmQBH) | 10 to 12 mm x mrad (300μmQBH) | 10 to 12 mm x mrad (300μmQBH) | 10 to 12 mm x mrad (300μmQBH) | 10 to 12 mm x mrad (300μmQBH) | 10 to 12 mm x mrad (300μmQBH) | |

| 15 to 17 mm x mrad (400μmQBH) | 15 to 17 mm x mrad (400μmQBH) | 15 to 17 mm x mrad (400μmQBH) | 15 to 17 mm x mrad (400μmQBH) | 15 to 17 mm x mrad (400μmQBH) | 15 to 17 mm x mrad (400μmQBH) | 15 to 17 mm x mrad (400μmQBH) | |

| 25 to 28 mm x mrad (600μmQBH) | 25 to 28 mm x mrad (600μmQBH) | 25 to 28 mm x mrad (600μmQBH) | 25 to 28 mm x mrad (600μmQBH) | 25 to 28 mm x mrad (600μmQBH) | 25 to 28 mm x mrad (600μmQBH) | 25 to 28 mm x mrad (600μmQBH) | |

| Modulation Frequency | ≤5kHz | ≤5kHz | ≤5kHz | ≤5kHz | ≤5kHz | ≤5kHz | ≤5kHz |

| Preview Red Light Power | 200 μW | 200 μW | 200 μW | 200 μW | 200 μW | 200 μW | 200 μW |

| FIBER DELIVERY SYSTEM | |||||||

| Interface | QBH (LOC) | QBH (LOC) | QBH (LOC) | QBH (LOC) | QBH (LOC) | QBH (LOC) | QBH (LOC) |

| Length | 15/20m standard, other lengths optional | ||||||

| Diameter | 100/200/300/400/600 μm | 100/200/300/400/600 μm | 100/200/300/400/600 μm | 100/200/300/400/600 μm | 100/200/300/400/600 μm | 100/200/300/400/600 μm | 100/200/300/400/600 μm |

| Bending Radius | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm | 200 mm |

| ELECTRICAL RATINGS | |||||||

| Supply Voltage | 220VAC (-15% to +10%) Single-phase | 220VAC (-15% to +10%) Single-phase | 400VAC (-15% to +10%) 3-phase | 400VAC (-15% to +10%) 3-phase | 400VAC (-15% to +10%) 3-phase | 400VAC (-15% to +10%) 3-phase | 400VAC (-15% to +10%) 3-phase |

| OTHER SPECIFICATIONS | |||||||

| Operating Temperature | +10 to +40℃ | +10 to +40℃ | +10 to +40℃ | +10 to +40℃ | +10 to +40℃ | +10 to +40℃ | +10 to +40℃ |

| Storage Temperature | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ |

| Humidity | 10 to 85% | 10 to 85% | 10 to 85% | 10 to 85% | 10 to 85% | 10 to 85% | 10 to 85% |

| Cooling Method | Water Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling | Water Cooling |

| Cooling Medium | Distilled water/ Glycol Antifreeze | ||||||

| Dimension | 800×482.6×193.2 mm | 800×482.6×193.2 mm | 483×950×193 mm | 483×950×193 mm | 640×1173×1102 mm | 640×1173×1102 mm | 640×1173×1102 mm |

| Weight | 50(±3) kg | 55(±3) kg | 72(±3) kg | 80(±3) kg | 200(±20) kg | 240(±20) kg | |

MFMC-6000W-20000W

The 6000W-20000W High Power Multi-Module CW Laser series is renowned for merging the benefits of water cooling with a modular design. Though compact, this series stands out for its highly integrated system that requires no maintenance. It’s praised for its beam stability, exceptional beam quality, and reliability. Paired with the fiber laser QBH output head, it integrates well with robots or machinery tools, finding applications in laser cutting, new energy, construction machinery, automotive parts, aerospace, and many more.

Key Features:

- High Power with Stellar Beam Quality: Provides impressive wall-plug efficiency, high power density, and flat-head distribution.

- Even Energy Distribution: Reduces splashes during the cutting and welding phases.

- Exceptional Material Processing: Efficient on thin sheets and robust for thick materials.

- Compact and Maintenance-Free Design: Comes with an integrated modular system for better stability and reduced TCO.

- Cutting and Welding Prowess: Extensively used across sectors like hardware processing, automotive, shipping, medical sectors, and more.

Processing Material Capabilities:

- Stainless Steel Cutting ranges: 10mm, 30-40mm, 50mm.

- Carbon Steel Cutting ranges: 18-22mm, 20-40mm, 50mm.

- Metal Cutting: 20-50mm.

- Aluminum Cutting: 40mm.

Industry Applications:

- Telecommunication, Sheet Metal Processing, Construction, Shipbuilding, Home Appliances, Petrochemical, Advertising, 3C Consumer Electronics, Scientific Research, Aerospace, Photovoltaic, Packaging, Clocks, and Watches.

| Models | MFMC-6000W | MFMC-12000W | MFMC-15000W | MFMC-20000W |

| OPTICAL SPECIFICATIONS | ||||

| Nominal Power | 6000W | 12000W | 15000W | 20000W |

| Mode of Operation | CW/Modulated | CW/Modulated | CW/Modulated | CW/Modulated |

| Polarization | Random | Random | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% |

| Wavelength | 1080 ± 5 nm | 1080 ± 5 nm | 1080 ± 5 nm | 1080 ± 5 nm |

| Power Stability | ±1 % | ±1 % | ±1 % | ±1 % |

| Laser Beam Quality, BPP | 3.5 to 4.5 mm x mrad (100μmQBH) | |||

| 5 to 6.5 mm x mrad (150μmQBH) | ||||

| 6.5 to 9 mm x mrad (200μmQBH) | ||||

| Modulation Frequency | ≤5kHz | ≤5kHz | ≤5kHz | ≤5kHz |

| Preview Red Light Power | 200 μW | 200 μW | 200 μW | 200 μW |

| FIBER DELIVERY SYSTEM | ||||

| Interface | QBH | LOE | LOE | LOE |

| Length | 20m standard, other lengths optional | |||

| Diameter | 100/150/200 μm | 100/150/200 μm | 100/150/200 μm | 150/200 μm |

| Bending Radius | 200 mm | 200 mm | 200 mm | 200 mm |

| ELECTRICAL RATINGS | ||||

| Supply Voltage | 400 (-15% to +10%) VAC 3-phase | |||

| OTHER SPECIFICATIONS | ||||

| Operating Temperature | +10 to +40℃ | +10 to +40℃ | +10 to +40℃ | +10 to +40℃ |

| Storage Temperature | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ |

| Humidity | 10 to 80% | 10 to 80% | 10 to 80% | 10 to 80% |

| Cooling Method | Water Cooling | Water Cooling | Water Cooling | Water Cooling |

| Cooling Medium | Distilled water/ Glycol Antifreeze | |||

| Dimension | 1050×1385×1658 mm | 1050×1385×1658 mm | 1050×1385×1658 mm | 1050×1385×1658 mm |

| Weight | 534(±4) kg | 646(±5) kg | 726(±5) kg | 815(±5) kg |

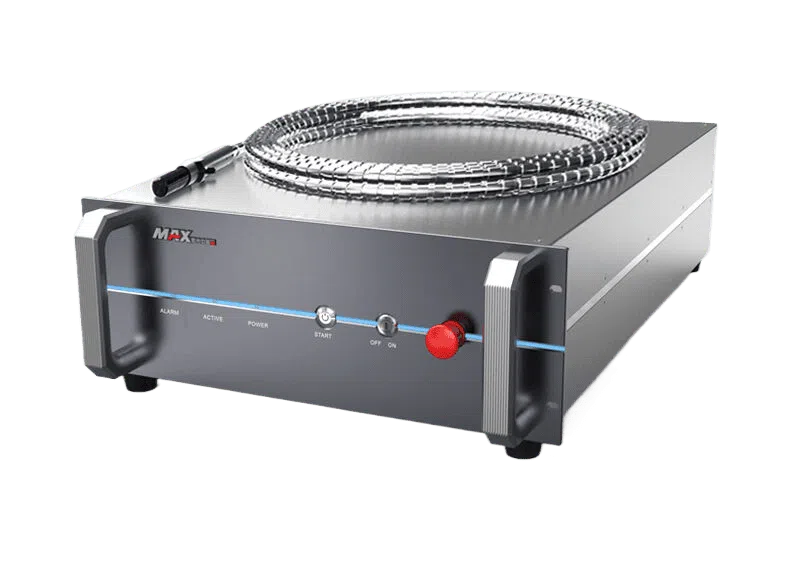

MFSC-1000X/1500X

MFSC 1000X-1500X Single Module CW Fiber Laser, based on modular design,has excellent beam quality and high stability, which structure is compact and water-cooling. The laser can be adjusted continuously, and the beam is transmitted be fiber and QBH connector, which is ideal for laser cutting, laser welding, etc . The laser is very suitable for system intergration with robot or machine tool, and is widely used for laser cutting, welding, 3D printing, electronics, automobile parts,aerospace, etc.

| Models | MFSC-1000X | MFSC-1500X |

| OPTICAL SPECIFICATIONS | ||

| Nominal Power | 1000W | 1500W |

| Mode of Operation | CW/Modulated | |

| Polarization | Random | |

| Power Tunability | 10 to 100% | |

| Wavelength | 1080 ± 10 nm | |

| Power Stability | ±1 % | |

| Laser Beam Quality, BPP | ≤1.5 mm x mrad (50μm QBH) | |

| Modulation Frequency | ≤20 kHz | |

| Preview Red Light Power | 150 μW | |

| FIBER DELIVERY SYSTEM | ||

| Interface | QBH (LOC) | |

| Length | 15m standard, other lengths optional | |

| Diameter | 50 (25) μm | 50 (35) μm |

| Bending Radius | 200 mm | |

| ELECTRICAL RATINGS | ||

| Supply Voltage | 220VAC (-15% to +10%) Single-phase | |

| OTHER SPECIFICATIONS | ||

| Operating Temperature | +10 to +40℃ | |

| Storage Temperature | -10 to +60℃ | |

| Humidity | 10 to 85% | |

| Cooling Method | Water Cooling | |

| Cooling Medium | Distilled water/ Glycol Antifreeze | |

| Dimension | 482.6×800×193mm (W×D×H) | |

| Weight | 53(±3) kg | 57(±3) kg |

MFSC-2000X/3000X

New generation 2000X-3000X Single Module CW Fiber Laser, which combine with high power, light weight, high quality beam quality and high light conversion efficiency. It is used for quick cutting, high frequency cutting and smooth surface cutting of carbon steel, stainless steel, brass and aluminum. It can meet the requirements of precision machining, 3C product welding and high- reflective material cutting. Product advantages : 1. High power output. 2. Fully sealed design. 3. More stable processing.

| Models | MFSC-2000X | MFSC-3000X |

| OPTICAL SPECIFICATIONS | ||

| Nominal Power | 2000W | 3000W |

| Mode of Operation | CW/Modulated | |

| Polarization | Random | |

| Power Tunability | 10 to 100% | |

| Wavelength | 1080 ± 10 nm | |

| Power Stability | ±1 % | |

| Laser Beam Quality, BPP | 1.1 to 1.5 mm x mrad (50μm QBH) | |

| 2.8 to 3.6 mm x mrad (100μm QBH) | ||

| Modulation Frequency | ≤5 KHz | |

| Preview Red Light Power | 200 μW | |

| FIBER DELIVERY SYSTEM | ||

| Interface | QBH (LOC) | |

| Length | 15m standard, other lengths optional | 20m standard, other lengths optional |

| Diameter | 50(100/200) μm | |

| Bending Radius | 200 mm | |

| ELECTRICAL RATINGS | ||

| Supply Voltage | 400VAC (-15% to +10%) 3-phase | |

| OTHER SPECIFICATIONS | ||

| Operating Temperature | +10 to +40℃ | |

| Storage Temperature | -10 to +60℃ | |

| Humidity | 10 to 85% | |

| Cooling Method | Water Cooling | |

| Cooling Medium | Distilled water/ Glycol Antifreeze | |

| Dimension | 482.6×950×193 mm | |

| Weight | 72(±3) kg | 80(±3) kg |

Q-Switch and Mopa Pulsed Fiber Laser Source

Product Description

MFP-20X/30X/50/

Q-switch series pulsed fiber laser is designed based on Q-switch oscillator and MOPA, offer a variety models from 20X to 50X. The laser is transmitted by fiber and isolator, and is controlled through a 25-pin interface. The Q-switched pulse fiber laser is suitable for intergration, and could meet the requirements of plastic marking, metal marking, engraving, coating removal,fine cutting, drilling, etc.

| Models | MFP-20X | MFP-30X | MFP-50X |

| OPTICAL SPECIFICATIONS | |||

| Nominal Power | 18~19W | 24~26W | 44~46W |

| Mode of Operation | Pulsed | Pulsed | Pulsed |

| Polarization | Random | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% | 10 to 100% |

| Wavelength | 1064±5nm | 1064±5nm | 1064±5nm |

| Power Stability | ≤5% | ≤5% | ≤5% |

| Laser Beam Quality M² | 1.1~1.6 | 1.1~1.6 | 1.1~1.6 |

| Pulse Energy | 0.7mJ | 0.75 mJ | 1mJ |

| Pulse Duration | 70~110 ns | 100~120 ns | 80~110 ns |

| Repetition Rate | 27.7~62.5 kHz | 30~60 kHz | 45~60 kHz |

| FIBER DELIVERY SYSTEM | |||

| Length | 1.9~3m standard,other lengths optional | ||

| Beam Diameter | 6~9mm | 6~9mm | 6~9mm |

| Beam Ellipticity | 90% | 90% | 90% |

| ELECTRICAL RATINGS | |||

| Supply Voltage | 24 VDC | 24 VDC | 24 VDC |

| OTHER SPECIFICATIONS | |||

| Operating Temperature | +10 to+40℃ | +10 to+40℃ | +10 to+40℃ |

| Storage Temperature | -10 to+60℃ | -10 to+60℃ | -10 to+60℃ |

| Humidity | 10 to 95% | 10 to 95% | 10 to 95% |

| Cooling Method | Air Cooling | Air Cooling | Air Cooling |

| Dimension | 244×200×73 mm | 345.5×266.2×120 mm | |

| Weight | 5 kg | 12 kg | 12 kg |

MFP-20H/30H

Q-switch series pulsed fiber laser is designed based on Q-switch oscillator and MOPA. The laser is transmitted by fiber and isolator, and is controlled through a 25-pin interface. The Q-switched pulse fiber laser is suitable for intergration, and could meet the requirements of plastic marking, metal marking, engraving, coating removal,fine cutting, drilling, etc.

| Model | MFP-20H | MFP-30H |

| OPTICAL SPECIFICATIONS | ||

| Nominal Power | 20W | 30W |

| Mode of Operation | Pulsed | Pulsed |

| Polarization | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% |

| Wavelength | 1064±5nm | 1064±5nm |

| Power Stability | ≤3% | ≤3% |

| Laser Beam Quality M² | 1.3~1.8 | 1.3~1.8 |

| Pulse Energy | 1mJ | 1.45 mJ |

| Pulse Duration | 80~120 ns | 80~120 ns |

| Repetition Rate | 20~80 kHz | 20kHz~80kHz |

| FIBER DELIVERY SYSTEM | ||

| Length | 1.9~3m standard,other lengths optional | |

| Beam Diameter | 6~8 mm | 6~8 mm |

| Beam Ellipticity | >90% | >90% |

| ELECTRICAL RATINGS | ||

| Supply Voltage | 24 VDC | 24 VDC |

| OTHER SPECIFICATIONS | ||

| Operating Temperature | +10 to+42℃ | +10 to+42℃ |

| Storage Temperature | -10 to+60℃ | -10 to+60℃ |

| Humidity | 10 to 95% | 10 to 95% |

| Cooling Method | Air Cooling | Air Cooling |

| Dimension | 287×219×94.6 mm | 345×266.2×120 mm |

| Weight | 7 kg | 12kg |

MFP-10W-70W

Q-switch series pulsed fiber laser is designed based on Q-switch oscillator and MOPA, offer a variety models from 10W-70W, and the peak power could reach 7KW. The laser is transmitted by fiber and isolator, and is controlled through a 25-pin interface. The Q-switched pulse fiber laser is suitable for intergration, and could meet the requirements of plastic marking, metal marking, engraving, coating removal,fine cutting, drilling, etc.

| Models | MFP-10W | MFP-20W | MFP-30W | MFP-50W | MFP-70W |

| OPTICAL SPECIFICATIONS | |||||

| Nominal Power | 10W | 20W | 30W | 50W | 70W |

| Mode of Operation | Pulsed | Pulsed | Pulsed | Pulsed | Pulsed |

| Polarization | Random | Random | Random | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% |

| Wavelength | 1064±5nm | 1064±5nm | 1064±5nm | 1064±5nm | 1064±5nm |

| Power Stability | ≤3% | ≤3% | ≤3% | ≤3% | ≤3% |

| Laser Beam Quality M² | 1.2~1.5 | 1.2~1.5 | 1.3~1.8 | 1.3~1.8 | 1.3~1.8 |

| Pulse Energy | 0.45mJ | 0.68 mJ | 1 mJ | 1 mJ | 1.45 mJ |

| Pulse Duration | 80~120 ns | 80~120 ns | 80~120 ns | 80~120 ns | 100~140 ns |

| Repetition Rate | 20~60 kHz | 30~60 kHz | 30~60 kHz | 50~80 kHz | 50~170 kHz |

| FIBER DELIVERY SYSTEM | |||||

| Length | 1.9~3m standard,other lengths optional | 1.9~3m standard,other lengths optional | 1.9~3m standard,other lengths optional | 1.9~3m standard,other lengths optional | 3m standard,other lengthsoptional |

| Beam Diameter | 6~8mm | 6~8mm | 6~8mm | 6~8mm | 6~8mm |

| Beam Ellipticity | 90% | 90% | 90% | 90% | 90% |

| ELECTRICAL RATINGS | |||||

| Supply Voltage | 24 VDC | 24 VDC | 24 VDC | 24 VDC | 24 VDC |

| OTHER SPECIFICATIONS | |||||

| Operating Temperature | +10 to+42℃ | +10 to+42℃ | +10 to+42℃ | +10 to+42℃ | +10 to+42℃ |

| Storage Temperature | 10 to+60℃ | 10 to+60℃ | 10 to+60℃ | 10 to+60℃ | 10 to+60℃ |

| Humidity | 10 to 95% | 10 to 95% | 10 to 95% | 10 to 95% | 10 to 95% |

| Cooling Method | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling |

| Dimension | 345×266.2×120 mm | 345×266.2×120 mm | 345×266.2×120 mm | 345×266.2×120 mm | 345×266.2×120 mm |

| Weight | 10 kg | 10 kg | 12 kg | 12 kg | 12 kg |

MFPT-20M-70M

MOPA pulsed fiber laser are designed based on MOPA structure, the pulse width and frequency can be adjustable,which makes more application possible. The pulse width could be adjusted from 2-350ns or 2-500ns, the peak power could reach up to 10KW, and the frequency could reach up to 4000kHz. The MOPA pulse fiber laser is ideal for alumina black marking,stainless steel multicolour marking, plastic marking, fine removel, laserengraving, etc.

| Models | MFPT-20M | MFPT-30M | MFPT-50M | MFPT-70M |

| OPTICAL SPECIFICATIONS | ||||

| Nominal Power | ≥20W | ≥30W | ≥50W | ≥70W |

| Mode of Operation | Pulsed | Pulsed | Pulsed | Pulsed |

| Polarization | Random | Random | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% |

| Wavelength | 1066±3 nm | 1066±3 nm | 1066±3 nm | 1066±3 nm |

| Power Stability | <5% | <5% | <5% | <5% |

| Laser Beam Quality | ≤1.3 | ≤1.3 | ≤1.4 | ≤1.5 |

| Pulse Energy | 0.7 mJ | 1 mJ | 1 mJ | 1 mJ |

| Pulse Duration | 2~350 ns | 2~350 ns | 2~500 ns | 2~500 ns |

| Repetition Rate | 1~4000 kHz | 1~4000 kHz | 1~4000 kHz | 1~4000 kHz |

| FIBER DELIVERY SYSTEM | ||||

| Length | 3m standard,other lengths optional | |||

| Beam Diameter | 5~7mm | 5~7mm | 5~7mm | 5~7mm |

| ELECTRICAL RATINGS | ||||

| Supply Voltage | 24 VDC | 24 VDC | 24 VDC | 24 VDC |

| OTHER SPECIFICATIONS | ||||

| Operating Temperature | 0 to +40℃ | 0 to +40℃ | 0 to +40℃ | 0 to +40℃ |

| Storage Temperature | -10 to+60℃ | -10 to+60℃ | -10 to+60℃ | -10 to+60℃ |

| Humidity | 10 to 95% | 10 to 95% | 10 to 95% | 10 to 95% |

| Cooling Method | Air Cooling | Air Cooling | Air Cooling | Air Cooling |

| Dimension | 287×219×95 mm | 355×266×120 mm | 355×266×120 mm | 355×266×120 mm |

| Weight | 6 kg | 8 kg | 11 kg | 11 kg |

MFP-100W/200W

Q-Switch Pulsed Fiber Laser (MFP 100W-200W) Series are maintenance-free fiber lasers based on the Q-switch technology and MOPA. These lasers deliver light whose emission wavelength is centered at 1060nm and peak power is up to 10KW or above. The light is guided to the work piece via a flexible metal-sheathed fiber cable. The laser’s running parameters are set by the user’s special controller via a DB-25 interface.

| Models | MFP-100W | MFP-200W |

| OPTICAL SPECIFICATIONS | ||

| Nominal Power | 100W | 200W |

| Mode of Operation | Pulsed | Pulsed |

| Polarization | Random | Random |

| Power Tunability | 5 to 100% | 5 to 100% |

| Wavelength | 1064±5 nm | 1064±5 nm |

| Power Stability | ≤5% | ≤5% |

| Laser Beam Quality M² | ≤[email protected] | ≤[email protected] |

| Pulse Energy | 1.5~8 mJ | 1.5~8 mJ |

| Pulse Duration | 150~190 ns | 180~220 ns |

| Repetition Rate | 20~200 kHz | 30~200 kHz |

| Full Power Repetition Rate | [email protected] | 30 @6.7 mJ |

| FIBER DELIVERY SYSTEM | ||

| Length | 5m standard,other lengths optional | |

| Beam Diameter | 5~9 mm | 5~9 mm |

| Beam Ellipticity | 90% | 90% |

| ELECTRICAL RATINGS | ||

| Supply Voltage | 220 VAC Single-phase | |

| OTHER SPECIFICATIONS | ||

| Operating Temperature | +10 to+35℃ | +10 to+35℃ |

| Storage Temperature | -10 to+60℃ | -10 to+60℃ |

| Humidity | 10 to 95% | 10 to 95% |

| Cooling Method | Air Cooling | Air Cooling |

| Dimension | 540.4×482.6×131.3 mm | |

| Weight | 21 kg | |

MFPT-100M+300M+

MOPA pulsed fiber laser are designed based on MOPA structure, the pulse width and frequency can be adjustable,which makes more application possible. The pulse width could be adjusted from 10-500ns, the peak power could reach up to 10KW, and the frequency could reach up to 4000kHz. The MOPA pulse fiber laser is ideal for alumina black marking,stainless steel multicolour marking,plastic marking, fine removel, laserengraving, etc.

| Models | MFPT-100 M+ | MFPT-120 M+ | MFPT-150 M+ | MFPT-200 M+ | MFPT-250 M+ | MFPT-300 M+ |

| OPTICAL SPECIFICATIONS | ||||||

| Nominal Power | ≥100W | ≥120W | ≥150W | ≥200W | ≥250W | ≥300W |

| Mode of Operation | Pulse &Continuous | Pulse &Continuous | Pulse &Continuous | Pulse &Continuous | Pulse &Continuous | Pulse &Continuous |

| Polarization | Random | Random | Random | Random | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% | 10 to 100% |

| Wavelength | 1060~1070nm | 1060~1070nm | 1060~1070nm | 1060~1070nm | 1060~1070nm | 1060~1070nm |

| Power Stability | <5% | <5% | <5% | <5% | <5% | <5% |

| Laser Beam Quality M2 | <1.6,typical value 1.3 | <1.6,typical value 1.3 | <1.6,typical value 1.3 | <1.6,typical value 1.3 | <1.6,typical value 1.3 | <1.6,typical value 1.3 |

| Pulse Energy | 1.8 mJ | 1.8 mJ | 1.8 mJ | 1.8 mJ | 1.8 mJ | 1.8 mJ |

| Pulse Duration | 10~500 ns | 10~500 ns | 10~500 ns | 10~500 ns | 10~500 ns | 10~500 ns |

| Repetition Rate | 1~4000 kHz | 1~4000 kHz | 1~4000 kHz | 1~4000 kHz | 1~4000 kHz | 1~4000 kHz |

| FIBER DELIVERY SYSTEM | ||||||

| Length | 5m standard,other lengths optional | 5m standard,other lengths optional | 5m standard,other lengths optional | 5m standard,other lengths optional | 5m standard,other lengths optional | 5m standard,other lengths optional |

| Beam Diameter | 5~7mm | 5~7mm | 5~7mm | 5~7mm | 8±1mm | 8±1mm |

| ELECTRICAL RATINGS | ||||||

| Supply Voltage | 220 VAC Single-phase | 220 VAC Single-phase | 220 VAC Single-phase | 220 VAC Single-phase | 220 VAC Single-phase | 220 VAC Single-phase |

| OTHER SPECIFICATIONS | ||||||

| Operating Temperature | 0 to+40℃ | 0 to+40℃ | 0 to+40℃ | 0 to+40℃ | 0 to+40℃ | 0 to+40℃ |

| Storage Temperature | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ | -10 to +60℃ |

| Humidity | 10 to 95% | 10 to 95% | 10 to 95% | 10 to 95% | 10 to 95% | 10 to 95% |

| Cooling Method | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling | Air Cooling |

| Dimension | 490.4×422×131.3 mm | 490.4×422×131.3 mm | 490.4×422×131.3 mm | 490.4×422×131.3 mm | 490.4×422×131.3 mm | 490.4×422×131.3 mm |

| Weight | 25 kg | 25 kg | 25 kg | 25 kg | 25 kg | 25 kg |

MFPT-500W

The MFPT-500W MOPA fiber laser is one of the cutting-edge products of Maxphotonics, which is constructed with a main oscillator and a high power fiber amplifier (MOPA).Multiple power options and compact structure. Easy to operate, overall maintenance free, can be directly integrated into user equipment. A periodic pulse sequence with a wavelength of about 1060 nm and a peak power of more than 250 KW is used. The operating parameters of the laser are set by the 25Pin control interface, and the special controller of the customer can be used for the handheld laser. Mainly used in laser cleaning.

| Model | MFPT-500M |

| OPTICAL SPECIFICATIONS | |

| Nominal Power | 500W |

| Mode of Operation | Pulsed |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 1064 nm |

| Power Stability | ≤5% |

| Laser Beam Quality,BPP | ≤10 mm xmrad |

| Pulse Energy | 50 mJ |

| Pulse Duration | 30~500 ns |

| Repetition Rate | 10-3000 kHz |

| FIBER DELIVERY SYSTEM | |

| Interface | QBH |

| Length | 10m standard,other lengths optional |

| Diameter | 200μm |

| Beam Divergence Angle | ≤100 mrad |

| ELECTRICAL RATINGS | |

| Supply Voltage | 220 VAC Single-phase |

| Power Consumption | ≤2000 W |

| OTHER SPECIFICATIONS | |

| Operating Temperature | 0 to+40℃ |

| Storage Temperature | -10 to+60℃ |

| Humidity | 10 to 95% |

| Cooling Method | Water Cooling |

| Cooling Medium | Distilled water/Glycol Antifreeze |

| Dimension | 720×482.6×190 mm |

| Weight | 52 kg |

QCW Fiber Laser Source

Product Description

MFSQ-75W-1000W

The product has various compatibility and control modes, which can switch between pulse and continuous mode, and simultaneously handle the.processing tasks of two different lasers The pulse width waveform is flexible and adjustable, the heat dissipation isfast, and the electro-optical conversion rate is over 30%, which is another option for the long pulse width , high peak power applications. Main Feature: 1. High beam quality; 2. Alternative lamp pump lasers; 3. High photoelectric conversion efficiency; 4. Pulse and continuous working modes; 5. High pulse power, stable power, and high peak power.

| Models | MFSQ-75/750W | MFSQ-150/1000W |

| OPTICAL SPECIFICATIONS | ||

| CW Mode Max Power | 75W | 150W |

| Pulsed Mode Max Power | 750W | 1000W |

| Mode of Operation | CW/Modulated | CW/Modulated |

| Polarization | Random | Random |

| Power Tunability | 10 to 100% | 10 to 100% |

| Wavelength | 1080±10 nm | 1080±10 nm |

| Power Stability | 2% | 2% |

| Laser Beam Quality M² | 1.2 | 1.3(20um) |

| Pulse Energy | 7.5J | 25J |

| Pulse Duration | 0.1~50 ms | 0.1~50 ms |

| Repetition Rate | 1~5000 Hz | 1~5000 Hz |

| Preview Red Light Power | 100 μW | 100 μW |

| FIBER DELIVERY SYSTEM | ||

| Interface | QBH (LOC) | QBH (LOC) |

| Length | 10 m standard,other lengths optional | |

| Diameter | 14/20/50μm | 14/20/50μm |

| Bending Radius | 200 mm | 200 mm |

| ELECTRICAL RATINGS | ||

| Supply Voltage | 220VAC | 220VAC |

| Peak Power Consumption | 2 KW | 2.5 KW |

| OTHER SPECIFICATIONS | ||

| Operating Temperature | +10 to+40℃ | +10 to+40℃ |

| Storage Temperature | 10 to +60℃ | 10 to +60℃ |

| Humidity | 10 to 85% | 10 to 85% |

| Cooling Method | Air Cooling | Air Cooling |

| Dimension | 586×420×142 mm | 536×357×130.4 mm |

| Weight | 30 kg | 32 kg |

MFSAQ-1000W/2000W

The product has various compatibility and control modes, which can switch between pulse and continuous mode, and simultaneously handle the.processing tasks of two different lasers The pulse width waveform is flexible and adjustable, the heat dissipation isfast, and the electro-optical conversion rate is over 30%, which is another option for the long pulse width , high peak power applications.

| Model | MFSQ-1000/2000W |

| OPTICAL SPECIFICATIONS | |

| CW Mode Max Power | 1000W |

| Pulsed Mode Max Power | 2000W |

| Mode of Operation | CW/Modulated |

| Polarization | Random |

| Power Tunability | 10 to 100% |

| Wavelength | 1080±10 nm |

| Power Stability | 3% |

| Laser Beam Quality M² | 2.5(50um) |

| Pulse Energy | 60J |

| Pulse Duration | 0.1~50 ms |

| Repetition Rate | 1~5000 Hz |

| Preview Red Light Power | 100 μW |

| FIBER DELIVERY SYSTEM | |

| Interface | QBH(LOC) |

| Length | 15m standard,other lengths optional |

| Diameter | 30/50μm |

| Bending Radius | 200 mm |

| ELECTRICAL RATINGS | |

| Supply Voltage | 220VAC |

| Rated Power | 7 KW |

| OTHER SPECIFICATIONS | |

| Operating Temperature | +10 to+40℃ |

| Storage Temperature | -10 to+60℃ |

| Humidity | 10 to 85% |

| Cooling Method | Water Cooling |

| Dimension | 950×482.6×193.2 mm |

| Weight | 68 kg |

Cargo Shipping

Shipping Information

Shipping Time and Costs

- Delivery Timeframe: 5-10 business days.

- Machines: Fees calculated at checkout or via email at [email protected].

- Accessories: Fees calculated at checkout or via email.

- Consumables: Shipped free of charge.

IMPORTANT NOTICE: Free shipping is exclusive to laser consumables. For discrepancies at checkout, contact us for actual shipping costs.

Order Tracking

- Confirmation: Receive an email upon successful order placement.

- Shipping Notification: Includes order number, courier, and tracking number. Track your order via email for updates, modifications, and shipping details.

Important Notes

Delivery Address

- Confirm your address before finalizing your order. To change it, email [email protected] within 48 hours of purchase.

Damage and Returns

- For transit damage due to force majeure, contact [email protected] immediately upon receipt.

- To cancel an order, contact us rather than refusing the package to avoid risks of loss or damage.

Non-receipt and Package Damage

- If not received within 7 days past the delivery date, email [email protected]. We are not liable for delays not reported within this timeframe.

- Report any package or product damage on the day of receipt with photos/videos to [email protected] for assistance.

Technical Support After Purchase

- For technical support, take detailed inventory and photos of unpacked items and contact [email protected] promptly. We provide support via email or online contact.

return & refund policy

1. Overview

We strive for your satisfaction with every order. Understanding that returns may sometimes be necessary, we offer a refund in USD, provided the goods meet our policy requirements.

2. How to Return

Before Delivery

- Email: Send a request to [email protected] to cancel and refund your order.

- Note: Avoid initiating a bank refund to prevent fees and delays. Any bank fees incurred will be deducted from your refund.

After Delivery

- Email: Contact [email protected] for return assistance.

- Conditions: Adhere to our return conditions. Be prepared for a service fee and transportation costs.

3. Return/Refund Conditions

Returns within 15 days of delivery are accepted under the following conditions, along with the original receipt and a refund service fee:

- Not Packed, Not Shipped: 4.4% service fee for machines, accessories, and consumables.

- Packaged, Not Shipped: 10% for machines; 20% for accessories and consumables.

- Shipped, Unopened: 20% for machines; 25% for accessories and consumables.

- Opened, Unused: 30% for machines; 50% for accessories and consumables.

- Opened, Used: 50% for machines; 80% for accessories and consumables.

Important: Service fees apply due to instant fund deductions by payment platforms. Bank charges, taxes, and shipping expenses are deducted from refunds. No exchanges. Items must return in pristine condition, with machinery/components having no more than 3 uses. Stand-alone consumables are non-returnable. For laser service products, our company does not accept refunds.

4. Refund Processing Time

- Packing Details: Include a packing list, order number, and customer name in your return package.

- Tracking: If returning the order yourself, email the tracking number to [email protected].

- Timeline: Refunds typically processed in 10-15 business days post-return inspection. Confirmation emails will be sent, followed by bank processing.

5. Disclaimer

- Approval: Only approved returns are accepted.

- Rights: DaG machinery reserves the right to refuse returns not meeting policy requirements.

- Shipping: Returns must be sent to the address provided in your return confirmation. No on-site returns.

6. Questions?

For any inquiries, email us at [email protected].

warranty period

The warranty period is 2 years for laser source power less than 12000W, 3 years for 15000-20000W, and 5 years for 30000W and above.