DΛGCNC | MACHINES

Are you looking for a trusted shop to buy new CNC metal machines online at a lower price or purchase used CNC metal machines from local shops or overseas manufacturers for small businesses, home shops, schools, education, teaching, training, hobbyists, commercial use or industrial manufacturing? DAGCNC is the most trusted place for beginners and professionals to buy the best CNC metal machines. It sells the most popular and affordable CNC metal machines at the lowest prices and provides 24/7 elite team-free pre-sales and after-sales services to meet your budget needs. At DAGCNC, you can find various types of affordable CNC bending machines, CNC laser cutting machines, laser cleaning machines, laser welding machines, jewelry laser spot welding machines for metal fabrication, sheet metal processing, metal bending, mould repair, jewelry repair, rust removal, paint removal, oil removal, metal cutting and welding, etc. Styles and types include mini, small, desktop, tabletop, handheld, portable, backpack, cart, large size, low power, high power, etc., to meet your various needs and budgets. You can consult and purchase online to meet your business plan, and let us become long-term partners!

CNC bending machines use matching moulds (general or special moulds) to bend cold metal sheets into workpieces of various geometric cross-sectional shapes. DAGCNC provides different types and tonnages of electro-hydraulic servo CNC bending machines, full servo pure electric CNC bending machines, down-action CNC bending machines, top-acting CNC bending machines, and ball screw CNC bending machines for processing metal materials such as stainless steel, carbon steel, copper, iron, aluminum and its alloys.

.png)

.png)

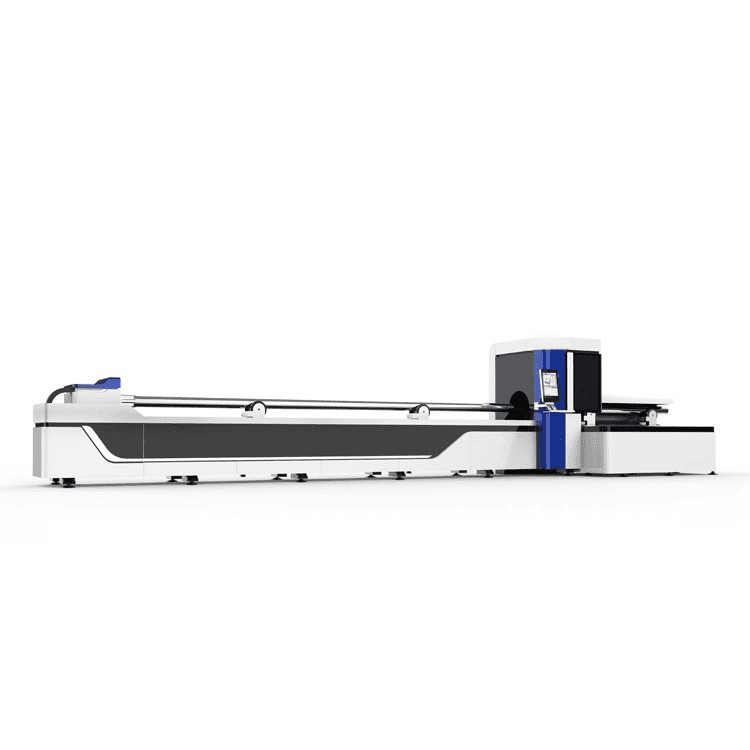

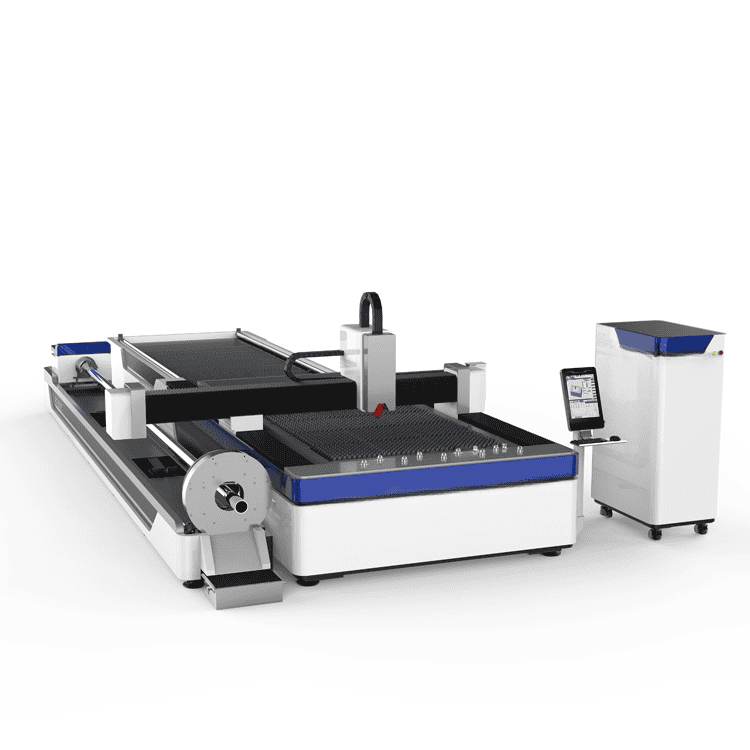

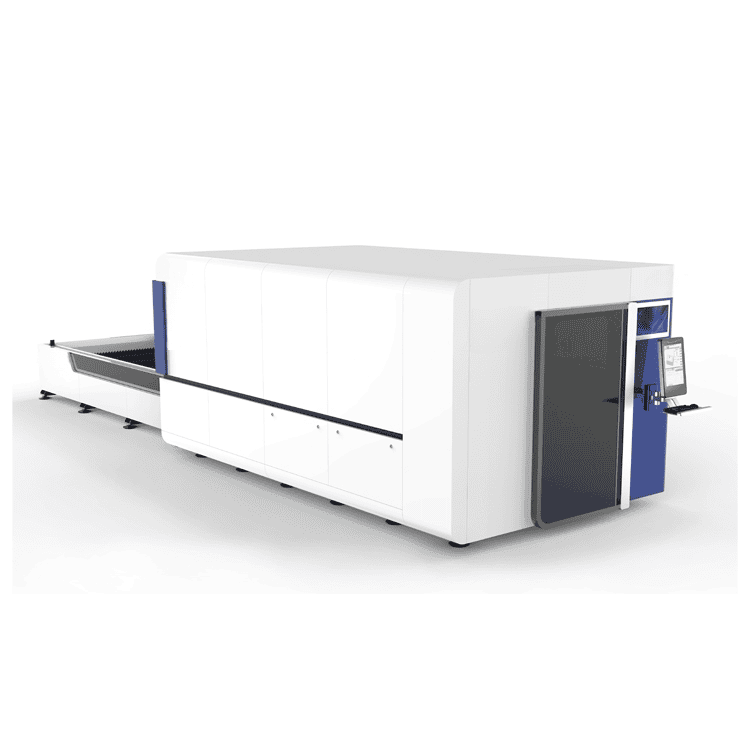

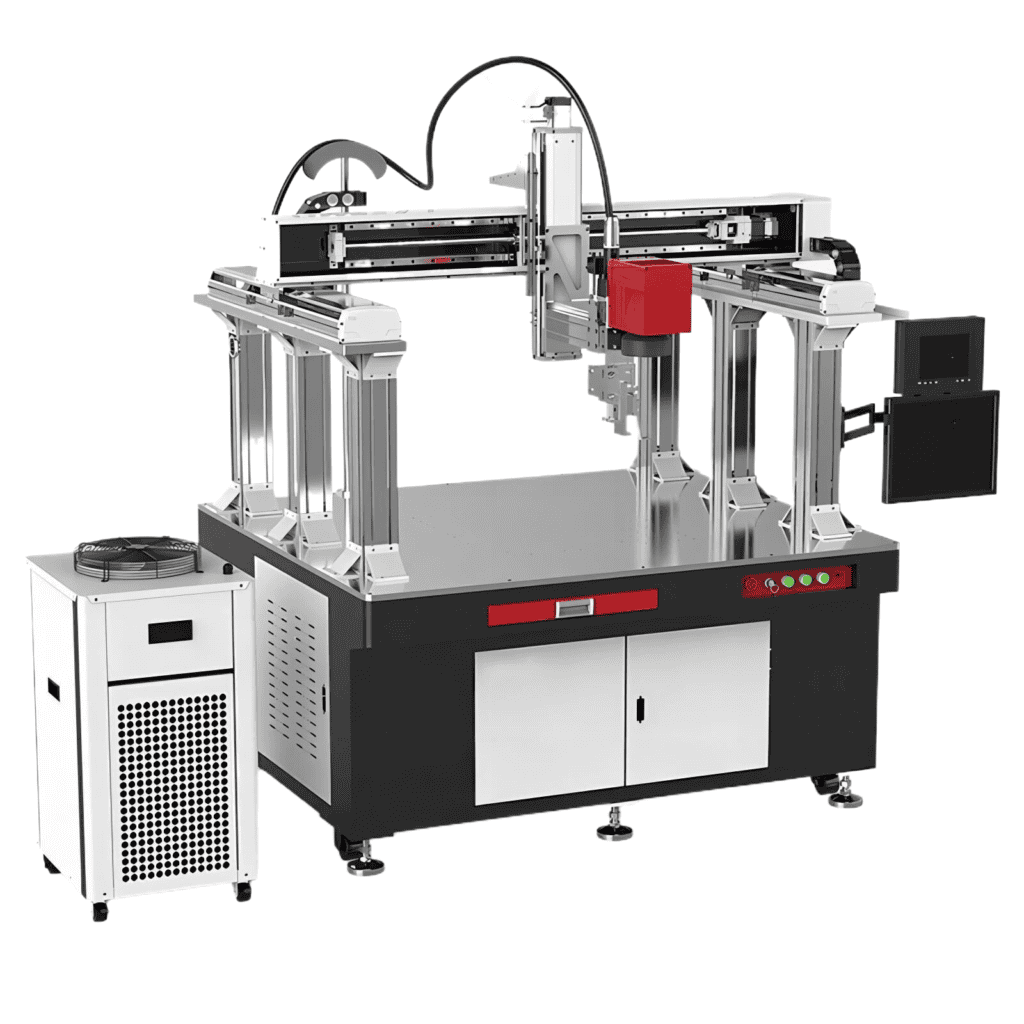

CNC metal laser cutting machine is an automated laser processing system with a computer numerical controller. It focuses the laser beam into a high-power density beam, irradiates it to the surface of the workpiece, makes the material reach the melting point or boiling point, and blows away the molten or vaporized metal through high-pressure gas, finally forming a slit to achieve the purpose of cutting. It is an excellent cutting tool for metal plates, tubes, rods, and strips. It can cut flat and bevelled metal shapes and profiles. It has a robotic arm and can even perform personalized 3D metal cutting. Laser cutting replaces the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, no restrictions on cutting patterns, automatic typesetting to save materials, smooth incisions, and low processing costs. It is an ideal metal-cutting tool for modern metal processing.

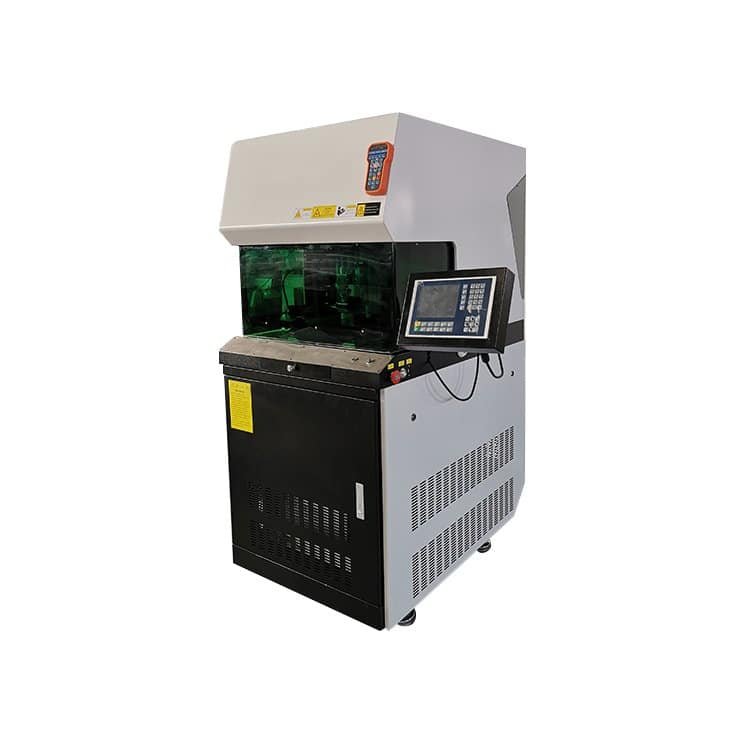

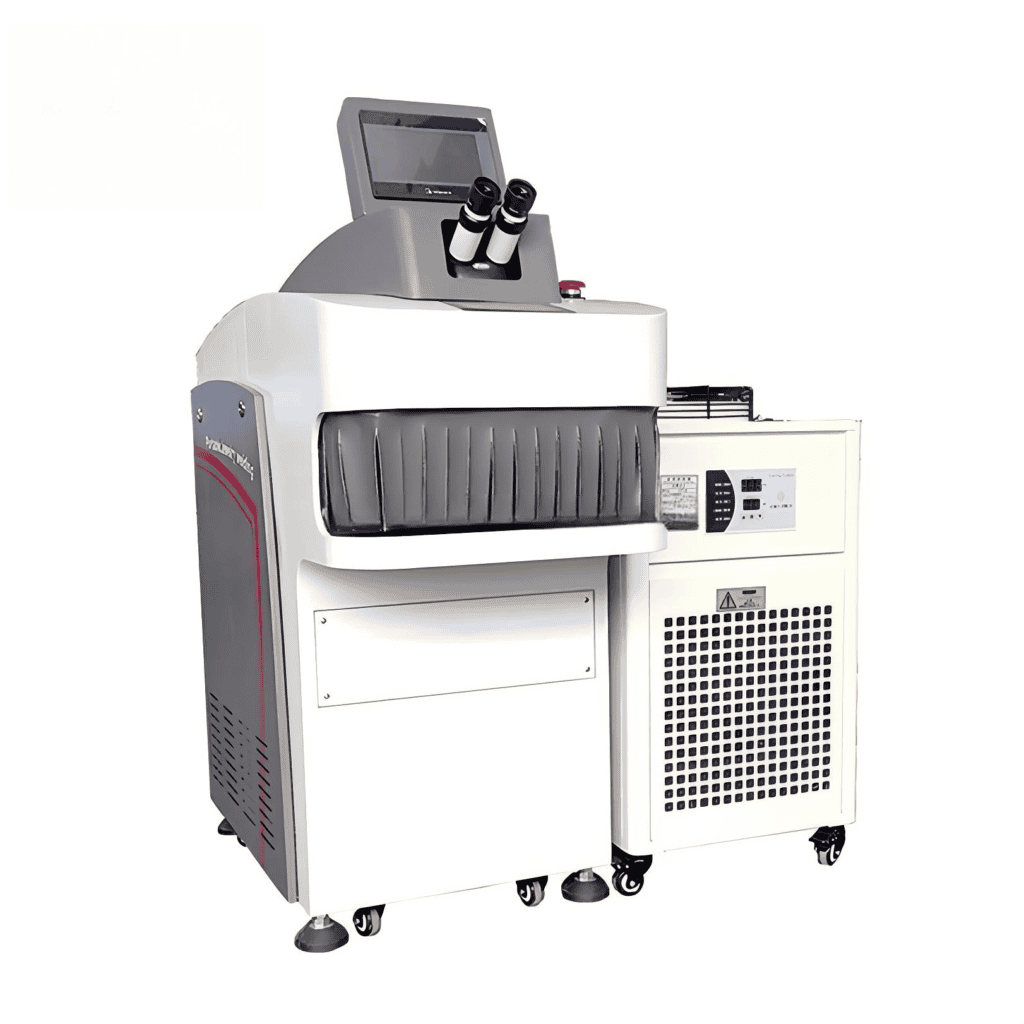

A metal laser welding machine uses a high-energy-density laser beam to heat the surface of the welding material locally. The laser energy melts the material through heat conduction to form a fixed molten pool. DAGCNC provides various types of metal laser welding machines, such as YAG and fiber lasers, with powers of 100W, 200W, 1000W, 2000W, 3000W, etc., which can meet the needs of spot welding, butt welding, lap welding, T-butt welding, seam welding, narrow welds, deep welds, kiss welding, etc. in the manufacturing of metals (titanium, nickel, tin, copper, aluminum, iron, stainless steel, carbon steel, etc.). It suits kitchenware, aerospace, automobiles, new energy batteries, electronic equipment and components, commerce, shipping, chemical and medical industries, and micro and precision components.

Jewelry laser welding machines are specially used for gold and silver jewelry, chain production, medical equipment, aluminum alloy dentures, instruments and meters, electronic component hole filling, spot welding sand holes, welding inlays, etc. The welding is firm, beautiful, and does not deform. It can be widely used in jewelry repair shops, shopping mall counters, watch repair shops, glasses repair shops, dental clinics, hardware repair shops, electronic repair shops, etc.

A laser cleaning machine can clean a lot of materials. It can remove coatings on metal or glass surfaces and quickly remove paint. It can not only remove all of them but also clean the surface paint layer by layer; promptly remove rust and various oxides from metal surfaces; remove grease, resin, glue, dust, stains, and production residues; roughen metal surfaces; remove rust and oil before welding of automotive parts, as well as oxides and stains after welding; clean moulds, such as tyre moulds, electronic moulds, and food moulds; remove oil stains after production and processing of precision parts; quickly clean up nuclear power parts maintenance; oxide treatment, paint removal, and rust removal during the production or maintenance of aerospace weapons and ships; clean metal surfaces in small spaces; clean cultural relics, clean rocks, and clean the exterior surfaces of buildings.

Metal CNC refers to machining metal materials using numerical control machine tools (CNC machine tools). CNC (Computer Numerical Control) controls machine tools by computers rather than manual control by machinists. New machine tools in CNC programming enable the industry to produce parts continuously with a precision that was unimaginable a few years ago. If the program is prepared correctly and the computer is programmed correctly, the same part can be replicated repeatedly with the same precision. High-precision, high-speed and high-efficiency metal processing can be achieved.

Metal CNC processing usually includes milling, turning, drilling, cutting, bending, welding, cleaning, etc. Through program control on CNC machine tools, the motion trajectory and processing parameters of the tool on the metal (stainless steel, carbon steel, low carbon steel, brass, copper, aluminium, iron, titanium, alloy) workpiece are accurately controlled to achieve the processing and production of complex parts.

CNC metal machines are intelligent processing kits popular in small and medium-sized enterprises for commercial purposes, training, school education, industrial manufacturing, and modern intelligent factories. It is composed of a bed, controller, spindle, gantry, operating system, software, motor, drive, worktable, ball screw, guide rail, power supply, chuck, vacuum pump, limit switch, rack, pinion and other parts and accessories. It can smoothly cut metal and accurately bend any geometric shape on hard metal. No matter what metal material, computer-controlled machine tools can handle it easily.

CNC machine tools use digital signals to control their movement and processing. A computer control system pre-programms the machine tool’s movement trajectory, speed, and processing parameters, thereby realizing the processing of parts.

1. Digital signal generation: Write the processing program through computer programming software and convert the various instructions and parameters required in the processing process into digital signals that the machine tool can recognize and execute.

2. Control system: The control system of CNC machine tools consists of hardware and software. Hardware includes computers, CNC devices, servo drives, etc., which receive and process digital signals and convert them into motion control signals for machine tools. The software is responsible for writing processing programs and controlling the machine tool’s movement trajectory, speed, and other parameters.

3. Motion control: The motion control of CNC machine tools mainly includes position, speed, and acceleration control. Through CNC devices and servo drives, digital signals are converted into electrical signals to control the movement of each axis of the machine tool and realize the processing of parts.

4. Process monitoring: CNC machine tools can monitor various processing parameters in real-time, such as tool position, cutting force, processing speed, etc., and feedback on the monitoring results to the control system. The control system makes adjustments based on the feedback information to ensure the accuracy and stability of the processing process.

1. Processing program writing: The operator uses computer programming software to write the processing program according to the parts’ processing requirements. The program includes tool path, cutting parameters, and processing sequence information.

2. Processing program transmission: The written processing program is transmitted to the CNC machine tool’s control system through the network or storage medium. The control system receives the processing program for analysis and processing.

3. Machine tool preparation: The operator installs appropriate tools and fixtures according to the processing program’s requirements, adjusts and calibrates the machine tool, and ensures it is in normal working condition.

4. Parameter setting: The operator sets the processing parameters according to the processing program’s requirements, including cutting speed, feed speed, cutting depth, etc. These parameters affect the cutting quality and efficiency during the processing process.

5. Start the machine tool: The operator loads the processing program into the control system of the CNC machine tool and starts the machine tool. The control system will control the movement of each axis of the machine tool according to the processing program’s requirements to realize the processing of parts.

6. Processing monitoring: During the processing process, the operator needs to monitor the machine tool’s operating status and processing quality in real-time. CNC devices and monitoring equipment can obtain information such as cutting force, tool position, processing speed, etc., and perform real-time analysis and adjustment.

7. Processing completed: When the processing program is completed, the machine and tool will automatically stop moving. The operator can remove the processed parts and conduct a quality inspection and subsequent processing.

1. It can process parts with complex shapes and improve production efficiency and quality.

2. It can reduce human and measurement errors and improve processing accuracy and repeatability.

3. It can reduce tool replacement and adjustment time and improve equipment utilization.

4. It can realize flexible production and adapt to the production needs of multiple varieties and small batches.

5. It can realize advanced functions such as intelligence, networking, and integration and improve production management.

Before purchasing CNC machine tools, enterprises need to analyze their production needs and determine the technical requirements of CNC machine tools, such as model, quantity, precision, etc. If you buy a large laser cutting machine to cut small crafts, it will waste a lot of money, and the effect will not be good. So before purchasing, you must communicate clearly with the salesperson to let him know your purpose, including the size of the workpiece, the material of the workpiece, the processing effect, etc.

Enterprises should screen potential CNC machine tool suppliers through market research channels and conduct detailed evaluations, including enterprise scale, technical strength, product quality, after-sales service, etc. After screening out suppliers that meet the requirements, enterprises need to communicate with them to understand the detailed configuration, price, delivery cycle, etc., of CNC machine tools.

Before purchasing, let the sales manager make samples according to your design to ensure the performance of the selected machine tool so that you can see the actual processing effect and usage time.

After selecting a supplier, the company needs to negotiate with it, and signing a complete contract is the best guarantee to safeguard its legitimate rights and interests. First, the contract should clearly state the purchased machine model, configuration, price, delivery time and delivery method, training method, warranty terms, specific payment method, etc. Before signing the contract, the company needs to read the terms of the agreement carefully, clarify the rights and responsibilities of both parties and the liability for breach of contract, etc., to ensure the safety of the transaction.

After the CNC machine tool is delivered on time, the supplier’s technicians will help you open the packaging box and go to your workshop for inspection (if you pay for door-to-door delivery service, the technicians will arrive at your workshop before the machine tool arrives). You should carefully check whether the appearance of the machine tool is damaged during transportation. Check whether the parts and accessories are intact according to the packing list and contract terms. Next, let the technicians install the machine (including hardware assembly, software installation and debugging). After the installation is completed, the machine is spot-checked. If there is no problem with the completed project, the delivery inspection is completed. According to the contract agreement, the user should pay the balance.

After the CNC machine tool is accepted and officially delivered for use, the company must install and debug the equipment according to the installation, debugging, and operation manual requirements and train the operators to ensure the operation is standardized, safe, and reliable.

If you encounter hardware or software problems during use, you must contact the dealer to communicate, let the service staff understand the situation, and start troubleshooting. Do not handle it yourself; otherwise, if you are not familiar with the machine tool, accidents may occur, and the manufacturer may refuse to provide warranty service for the equipment. Regarding after-sales service, we can ask the CNC machine tool manufacturer to follow the contract agreement strictly. You can complain to the person in charge if you encounter deliberate delays or bad attitudes.

If you need to buy a CNC metal machine tool, DAG is your first choice. Please send us your detailed requirements and get an instant quote now.

© 2024 Shenzhen DAG Technology Industrial Co., Ltd.All Rights Reserved.

WhatsApp us