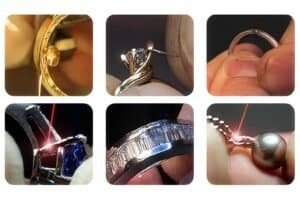

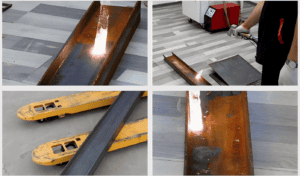

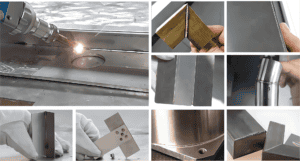

Fibre laser welding is revolutionizing how we join materials, from welding stainless steel to welding aluminium and copper alloys. Its unparalleled precision, material versatility, and wide range of applications, from handheld to CNC laser welding machines, make fibre laser welding machines a popular tool in the industry.

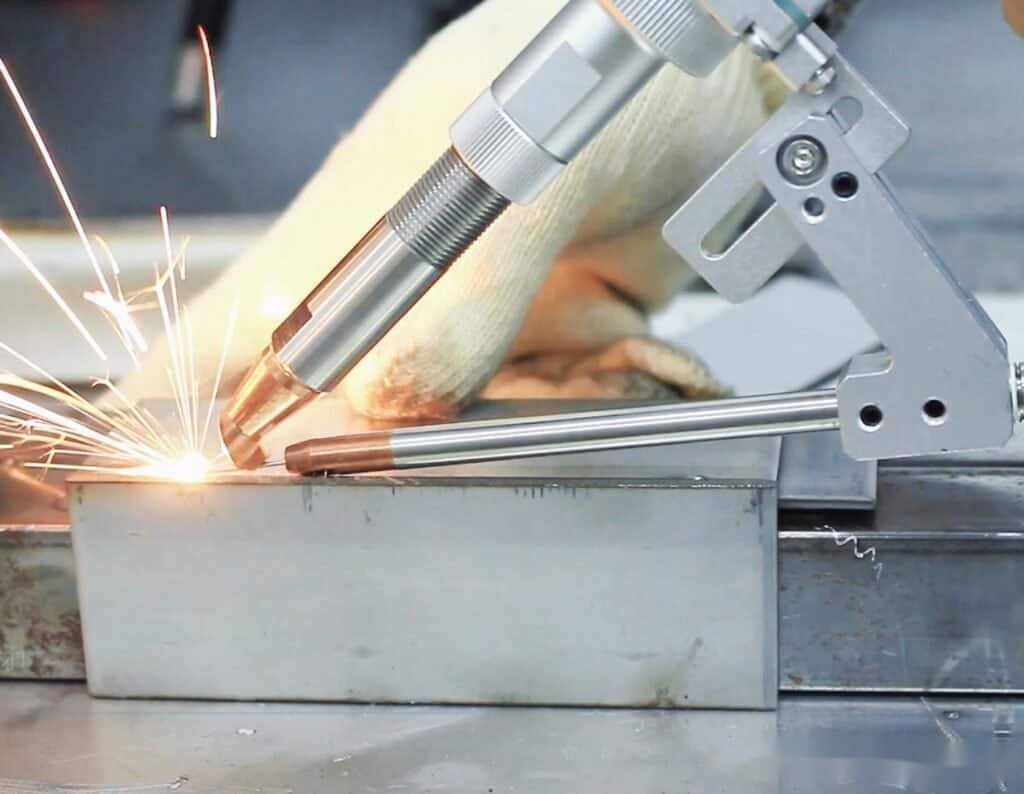

Choosing the best fibre laser welding machine requires understanding its key components, such as the laser head and gantry system, and its benefits to material joining, including lower distortion and ease of mastering the technique. Whether you choose a portable laser welder or a versatile 3-in-1 laser welder, knowing what suits your needs is essential.

Understand your welding needs

To effectively select a fibre laser welding machine that meets your specific requirements, it is essential to understand several key factors:

Materials and welding compatibility

1. Material compatibility: Make sure the fibre laser welding machine suits the materials you plan to use. Fibre lasers can process various materials, including metals, composites and thermoplastics.

2. Welding compatibility: Different machines are good at different tasks. Fibre lasers are ideal for processing thin and thick metal plates, and the thickness of the welded material varies with power.

Industry and application-specific requirements

● Industrial applications: Choose from handheld laser welding machines suitable for small to medium-sized jobs and robotic welding machines suitable for large industries that require high precision and productivity.

● Application-specific requirements: Tailor your selection to the unique needs of your application, considering factors such as material type, joint configuration, throughput and required weld quality

By carefully evaluating these aspects, you can choose a fibre laser welding machine that fits your budget and improves operational efficiency and product quality.

Key factors to consider when purchasing a Laser Welding Machine

Evaluate cost and longevity

Initial Purchase and Operating Costs: When considering a fibre laser welding machine, it is essential to evaluate not only the initial purchase price but also additional costs such as installation, training, and maintenance.

Long-term durability: Choose machines from reputable manufacturers known for durability and reliability. Ensure the machine has an efficient cooling system to maintain performance and extend service life.

Machine specifications and compatibility

Laser Specifications: Choose a laser welder with a power rating suitable for your needs—higher power for thicker materials and lower power for thinner materials. The laser source should provide the right balance of power and precision, focusing on beam Quality and stability.

Materials and welding needs: Make sure the welder is compatible with the type of materials and specific welding application you plan to use, such as spot or seam welding.

Support and operational efficiency

Comprehensive Support: Choose a vendor that offers extensive customer support, including training and after-sales service, to help you maximize your competition machine rating efficiency.

User Interface and Maintenance: A user-friendly interface and ease of maintenance are critical to operational efficiency. Consider machines that offer automated process control and integrated safety features for ease of use.

By carefully considering these factors, you can choose a fibre laser welding machine that meets your immediate production needs and provides long-term reliability and efficiency.

Cost Considerations and ROI

Initial investment and operating costs

Purchase Price Range: Fiber laser welding machine prices vary widely. Handheld models typically cost $1,000 to $10,000, while more sophisticated automated machines can cost $15,000 to $35,000.

Operating costs: Operating costs include consumables such as gas and electricity, in addition to purchases. Fibre lasers are known for their efficiency, which can help reduce electricity bills compared to other technologies.

Return on Investment (ROI)

Short-term return on investment: Fiber laser welders can provide a return on investment within 12 to 24 months through increased productivity and reduced labour costs.

Long-term benefits: Over time, savings from reduced material waste, lower labour costs, and increased throughput can significantly offset the initial cost.

total cost of ownership

A comprehensive budget: It’s crucial to consider all aspects of ownership, including energy efficiency and maintenance costs. The total cost of ownership goes beyond the initial price to cover potential productivity gains and long-term operational savings.

Financing Options: For businesses worried about upfront costs, financing to purchase a fibre laser cutting machine can spread the cost over time, easing cash flow and allowing for immediate utilization of the technology.

Evaluate machine quality and after-sales support

Choose high-quality manufacturers

When choosing a fibre laser welding machine, prioritize manufacturers specializing in laser technology. This specialization usually ensures that the machine is durable and can perform various demanding tasks optimally. Also, choose a manufacturer known for its robust customer support services. This should include comprehensive technical assistance, extensive warranty coverage, and the guarantee of ready-to-available spare parts. These factors are critical to maintaining machine performance and ensuring productivity is not hampered by technical issues.

Key machine parameters and material considerations

Before purchasing, it is necessary to evaluate specific technical parameters of the laser welding machine. Check the adjustable energy settings, beam diameter, pulse frequency, and monitor waveform capabilities. These parameters significantly influence the flexibility and efficiency of the machine when handling different materials and welding tasks. Additionally, consider the material thicknesses and laser types the machine can support and its parameter monitoring capabilities to ensure it meets your specific welding needs.

Understanding the Pros and Cons

Understanding the advantages and disadvantages of laser welding machines can guide you in making an informed decision. The primary benefits include precision, minimal distortion, high-speed welding, versatility, reduced material waste, and the ability to join dissimilar materials. However, potential drawbacks such as the high initial investment, the need for professional training, maintenance costs, and environmental considerations should also be considered. This comprehensive evaluation helps balance your expectations with the practicalities of operating and maintaining the machine.

Conclusion

Throughout this comprehensive exploration, we’ve scored the essential factors and considerations for choosing the most suitable fibre laser welder for your needs. From analyzing compatibility with materials and specific welding tasks to understanding the intricacies of CNC metal laser welding machines to evaluating costs, return on investment, and the critical role of after-sales support, the journey to selecting the suitable machine is informed by a nuanced understanding of these components. This knowledge equips you with the insight needed to enhance operational efficiency, ensure product quality, and confidently navigate the market’s service offerings.

Reflecting on the broader implications, the decision to invest in a fibre laser welder is not merely a purchase but a strategic move towards innovation and competitive advantage in the welding industry. The potential for significant returns, both in the short and long term, through improved productivity and reduced costs, underscores the value of making an informed choice. As we conclude, remember that the selection process is critical in harnessing the transformative power of fibre laser welding technology, poised to redefine the standards of precision, efficiency, and quality in your welding endeavours.

FAQs

How should I choose a fibre laser that suits my needs?

1. When choosing a fibre laser, focus primarily on system power and the thickness of the material you want to use. Fiber laser power is typically measured in watts, ranging from 10W to 10,000W. The power required increases with the thickness of the material to be cut or welded.

2. What criteria are critical when selecting a laser welding machine?

Selecting the suitable laser welding machine involves material compatibility, material thickness, specific welding applications, machine selection, power and energy output, pulse duration and frequency, beam delivery, and the cooling system.

3. What considerations are crucial when choosing a welding process?

Essential considerations in selecting a welding process include the type of material, material thickness, welding position, type of welding power source and available current, time constraints, and working conditions.

4. What should I consider when purchasing a welder?

When purchasing a welder, consider the primary power requirements, portability, size, weight, welding output, duty cycle, electrode selection, and shielding gas requirements. These factors will help ensure that the welder meets your specific needs.