The rapid development of laser cleaning technology has gradually entered people’s lives with its unique advantages, such as low damage to the base material, high cleaning accuracy, zero emission and no pollution. No doubt, applying laser cleaning technology to clean dirt on metal surfaces has an extensive prospect. However, the price of laser cleaning machines on the market ranges from tens to hundreds of thousands. Knowing how to choose a laser cleaning machine that suits you is necessary.

What is a laser cleaning machine?

Laser cleaning machines focus on cleaning and protecting equipment. Laser cleaning technology is a “green” cleaning process that does not require the use of chemical agents or cleaning fluids. The waste materials cleaned are solid powders that are small in size, easy to store, and recyclable, which can quickly solve the environmental pollution problems caused by chemical cleaning.

According to a large number of experimental results, laser cleaning machines vary according to the difference in thermal physical parameters between surface attachments and substrates:

When the thermal physical parameters of surface attachments and substrate materials differ, laser cleaning machines include ablation vaporization, thermal vibration and thermal shock machines, and sonic vibration crushers, such as laser cleaning of paint and rubber layers.

When the thermal physical parameters of surface attachments and substrate materials differ, the ablation vaporization machine, such as laser rust removal, is mainly at work.

Things to note when choosing a laser cleaning machine

- Clarify your needs: First, you must clarify your cleaning needs, including cleaning objects, cleaning effects, cleaning speed, etc. This will help you choose the right laser cleaning machine model and configuration.

- Understand the technical parameters: The technical parameters of the laser cleaning machine are essential indicators of its performance. You pay attention to parameters such as laser power, wavelength, scanning speed, etc., to ensure the selected settings meet your needs.

- Consider the cost: The cost of the laser cleaning machine includes the cost of equipment purchase, operation, and maintenance. It is best to choose according to your budget while considering the equipment’s long-term operating cost and benefits.

- Choose a reputable supplier: A reputable supplier can ensure that the laser cleaning machine you purchase is of reliable quality and offers guaranteed after-sales service.

Laser cleaning machine’s price

Having a fixed price for laser cleaning machines isn’t easy because they are generally customized. Generally speaking, the cost of a laser cleaning machine is related to its power. The higher the laser power, the more expensive it is. However, you must consider your specific needs when purchasing a laser cleaning machine. For example, if you need to clean floating rust, a low-power laser cleaning machine can meet your needs, while a high-power laser cleaning machine may damage the workpiece.

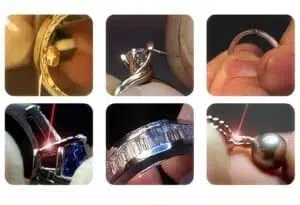

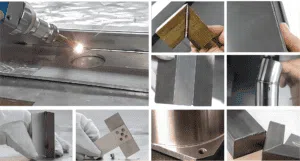

Application

Laser cleaning technology has been applied to fields such as the military industry, mould cleaning, surface treatment, microelectronics, cultural relics protection, medical treatment, and automobile processing.

Case Analysis

- A car manufacturer uses a laser cleaning machine to remove rust and oil stains from the surface of auto parts, improving their cleanliness and reducing the cost of subsequent processing.

- An electronics factory uses a laser cleaning machine to remove impurities from circuit boards, improving conductivity and reducing failure rates.

- A construction company uses a laser cleaning machine to clean a building’s glass curtain wall, improving its beauty and durability.

- A museum uses a laser cleaning machine to remove dirt from the surface of cultural relics, protecting their original appearance.

- A food factory uses a laser cleaning machine to clean the ink on the surface of food packaging, improving the hygiene standards of the product.