Affordable China top brand fiber laser source for sale

DΛGCNC | Fiber Laser Sources

Fiber laser machine core components - fiber laser source

Fiber laser source refers to a laser that uses rare earth-doped glass fiber as a gain medium. It is a type of solid laser source. Fiber laser source has the characteristics of high photoelectric conversion efficiency, simple structure, and good beam quality. It has become the mainstream direction of laser technology development and the main force of laser industry applications. Fiber laser source is small in size and occupies little space. It can be used occasionally and widely in downstream manufacturing and processing fields. Fiber laser sources can directly use optical fiber output, has high processing adaptability, and can adapt to any space processing application; in addition, the beam quality of fiber laser sources is relatively good, which can minimize costs and improve efficiency for manufacturing companies. Premium laser sources for cutting, marking, welding, and Cleaning – high precision, power, and efficiency.

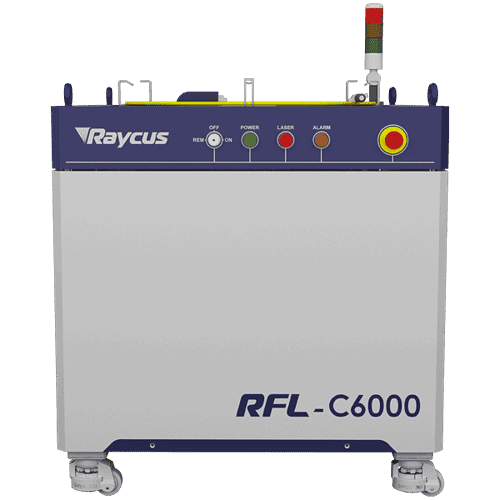

Raycus/MAX/JPT Fiber laser source

Wuhan Raycus

Raycus is recognized as the most outstanding fiber laser source manufacturer in China. It is the earliest company in China to engage in the research and development and large-scale production of high-power fiber lasers and core components. It is also China's most extensive fiber laser research and development and production base with global influence. As one of China's most trusted fiber laser suppliers, it has its own international fiber laser key component research and development centre. Its products range from low to high power, covering continuous fiber laser sources, pulsed fiber laser sources, quasi-continuous fiber laser sources, Q-switched fiber laser sources, etc.

MAX Fiber Laser Source

MAX Laser was founded in 2004 and focuses on the research and development, and production of lasers and core components. It is one of the first companies in China to introduce and localize the two core technologies of lasers and optical passive components.MAX Laser has a rich product line, including pulse device lasers, continuous device lasers, quasi-continuous device lasers, scientific research device lasers, semiconductor lasers, and various laser solutions and core components, such as pump sources, optical isolators, and photosynthetic products, which have been widely evaluated in aerospace, 3D printing, automobiles, petroleum, electronics, communications, photovoltaics, medical and other industries.

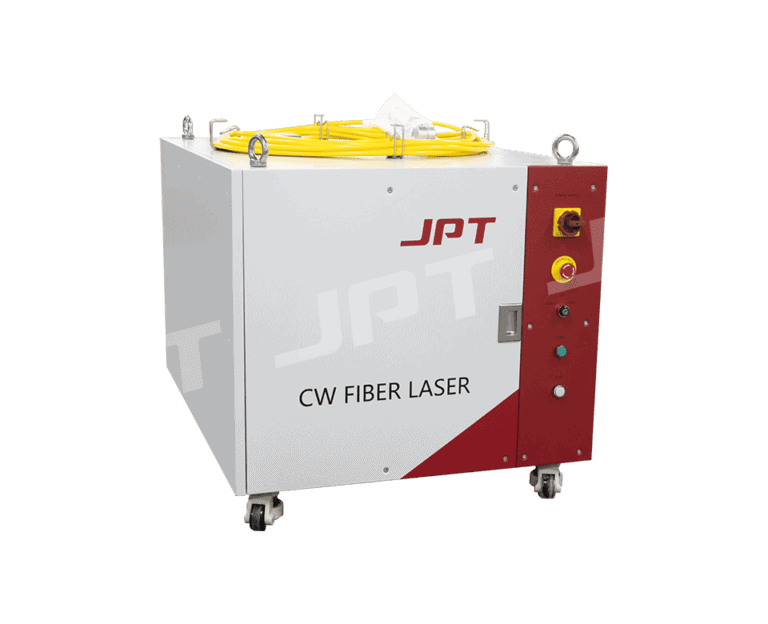

JPT Fiber Laser Source

Registered in 2006, Shenzhen JPT Opto-electronics Co., Ltd. is a National High-tech Enterprise. The company focuses on the R&D, production, sales, and technical services of lasers, intelligent equipments and optical devices. Based on laser technologies, JPT integrates leading technologies such as optics and measurement, motion control and machine vision, to create value for the customers.As the first manufacturer of MOPA fiber lasers in China, JPT adheres to the positioning of "laser +", to develop core laser technologies and focus on the laser core modules. Surrounding the key fields of consumer electronics, pan-semiconductors, new energy and bio-medical, JPT provides customers with diverse series of fiber lasers, solid lasers and ultra-fast lasers of various wavelength and modes. JPT provides thorough laser solutions, including precision welding, precision cutting and drilling, inspection and marking of semiconductor modules, passive components, FPC/PCB drilling and etc.

Video demonstration

Introduction to Fiber Laser Source

Fiber laser sources use doped fiber as a gain medium. Their working principle is stimulated radiation. They usually consist of three parts: gain fiber, pump source, and optical resonant cavity. The pump source uses external energy to reverse the number of gain medium particles. A laser oscillation output is formed when the gain in the resonant cavity is greater than the loss.

Application in material processing

Fiber laser sources are widely used in metal cutting, welding, marking and surface treatment in material processing. Due to the characteristics of flexible fiber lines, stable optical paths, and small beam spots, fiber lasers have unique advantages. Compared with traditional CO2 lasers, fiber lasers have low energy consumption, high efficiency, low cost, and simple maintenance, making them the first choice in material processing.

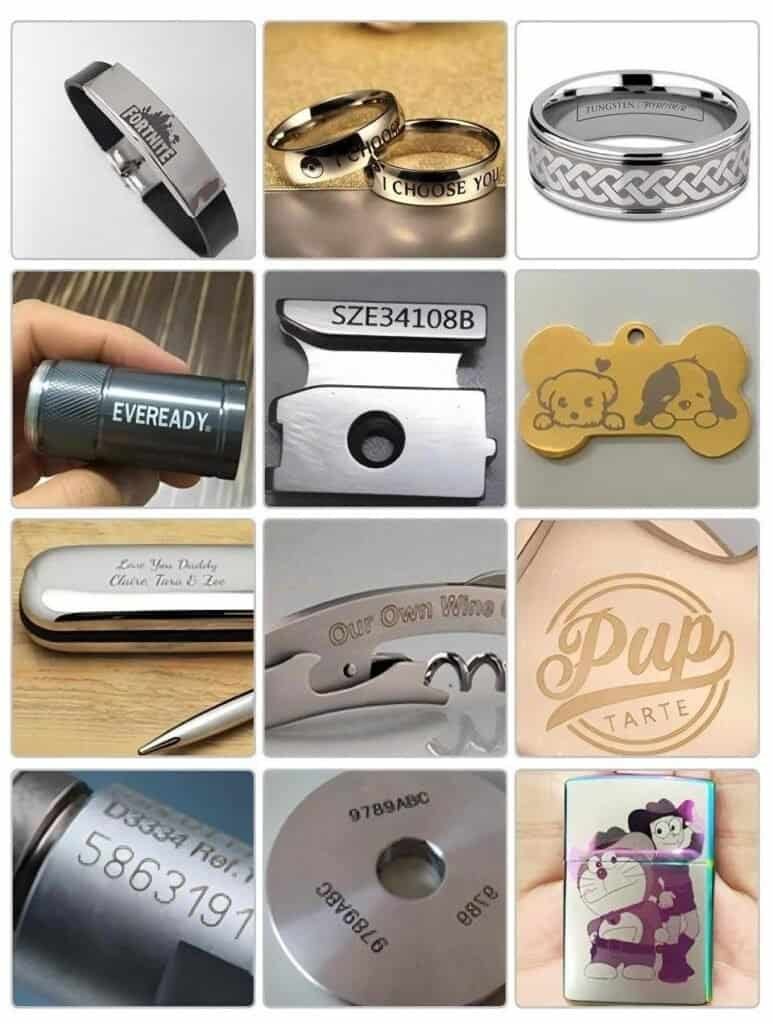

Marking Application

Pulse fiber lasers have excellent beam quality and reliability, the longest maintenance-free time, the highest comprehensive electro-optical conversion efficiency, pulse repetition frequency, the smallest volume, the simplest and most flexible use without water cooling, and the lowest operating cost. They are the only choice for high-speed and high-precision laser marking.

1. Efficient and accurate: Fiber laser marking can be as precise as 0.01mm and has a fast marking speed, making it especially suitable for mass production.

2. No damage to the object’s surface: Fiber laser marking will not damage the object’s surface; The marking is straightforward and does not quickly fade.

3. Traceability: Fiber laser marking can give the object a unique identification code, which is convenient for traceability and management.

4. Environmental protection and energy savings: The fiber laser marking process does not require ink and chemicals, there is no secondary pollution, and it saves energy.

Welding Application

The fiber laser source uses the laser beam’s energy to heat the metal material to a molten state. Then, by controlling the movement and power of the laser beam, the metal material is precisely welded.

1. Laser welding is a new method, mainly for welding machines of thin-walled materials and precision parts. It can realize spot welding, butt welding, lap welding, sealing welding and other welding methods.

2. The laser weld has a small width, heat-affected zone, and deformation.

3. The laser welding speed is fast, the weld is smooth and beautiful, and the weld quality is high after spraying or simple treatment after welding.

4. Laser welding has no pores, accurate control, small focus, high positioning accuracy, and is easy to automate.

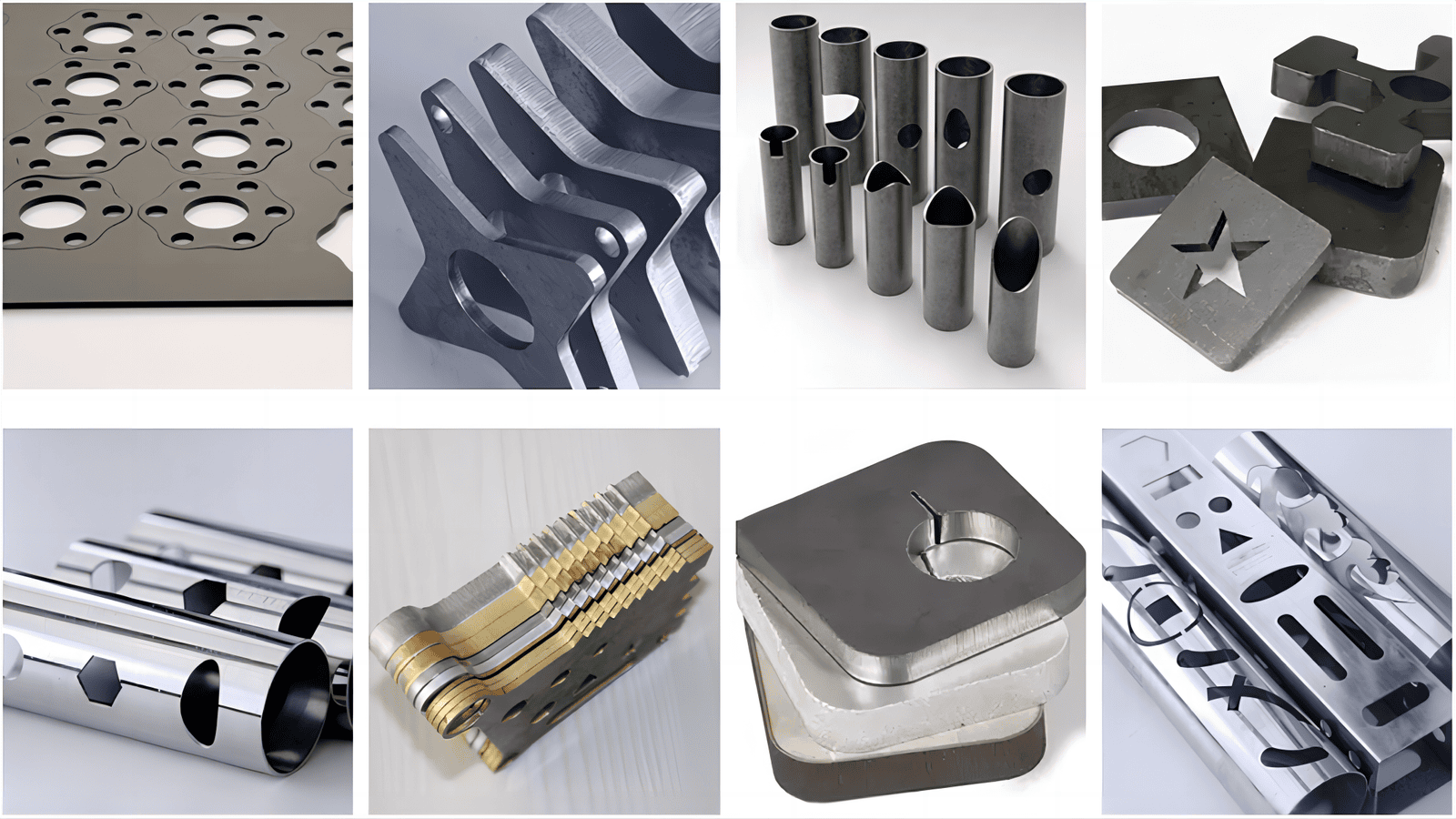

Cutting Application

The fiber laser source is a new type of fiber laser developed internationally. It outputs a high-energy-density laser beam and focuses it on the surface of the workpiece, causing the area irradiated by the ultra-fine focal spot to melt and vaporize instantly. Automatic cutting is achieved by moving the spot irradiation position through a CNC mechanical system.

1. High cutting accuracy: The laser cutting machine’s positioning accuracy is 0.05mm, and the repeated positioning accuracy is 0.03mm.

2. Narrow cutting slit: The laser beam is focused into a tiny light spot so that the focus reaches a very high power density, and the material is quickly heated to the degree of gasification, evaporating to form holes.

3. Smooth cutting surface: There are no burrs on the cutting surface, and the surface roughness of the cut is generally controlled within Ra6.5.

4. Fast cutting speed: The cutting speed can reach 10m/min, and the maximum positioning speed can reach 30m/min, much faster than the wire cutting speed.

5. Good cutting quality: No contact cutting; heat affects the cutting edge slightly

6. No damage to the workpiece: The laser cutting head will not contact the material’s surface to ensure the workpiece is not scratched.

7. Not affected by the shape of the workpiece: The laser processing is flexible, and any graphics can be processed, and pipes and other special-shaped materials can be cut.

8. Save mould investment: Laser processing does not require moulds; anno mould is consumed.

9. Save materials: Computer programming can be used to cut products of different shapes to maximize the utilization of materials.

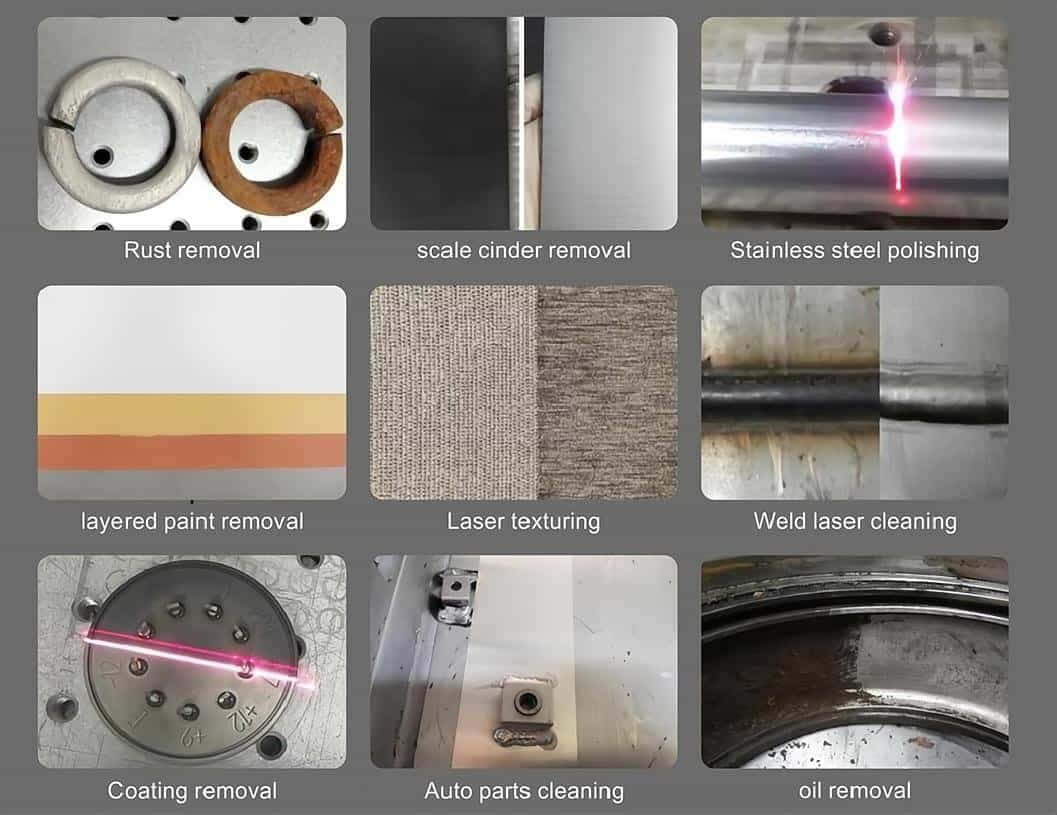

Cleaning Application

Laser cleaning uses a high-energy continuous or pulsed laser beam to act on the surface of pollutants, causing the contaminants to absorb the focused laser energy in an extremely short period, producing a series of photophysical reactions, and prompting the contaminants to separate from the matrix quickly. At the same time, the primary energy of the laser acts on the surface pollutants, causing minor damage to the matrix. As a non-mechanical contact processing, it does not require adding other chemical agents and media. In addition to the stripped pollutants, almost no other impurities are produced. It is a relatively “green” production technology.

1. Laser cleaning is a “green” method that does not require chemical agents or cleaning fluids. The waste materials cleaned are solid powders, which are small, easy to store, and recyclable. Laser cleaning can quickly solve the environmental pollution problems caused by chemical cleaning.

2. Traditional cleaning methods often involve contact cleaning, which consists of applying a mechanical force to the surface of the cleaning object, damaging it. Alternatively, the cleaning medium can be attached to the surface of the cleaned object and cannot be removed, resulting in secondary pollution. Laser cleaning, being non-abrasive and non-contact, solves these problems.

3. Lasers can be transmitted through optical fibers and used with manipulators and robots to achieve long-distance operation quickly. They can also clean parts that are difficult to reach with traditional methods, which can ensure the safety of personnel in some dangerous places.

4. Laser cleaning can remove various types of pollutants from the surface of multiple materials, achieving a cleanliness that conventional cleaning cannot reach. It can also selectively clean contaminants without damaging the surface of the materials.

What determines the power of a fiber laser source?

The power of a fiber laser source can range from a few watts to tens of kilowatts, and the specific power range depends on its application scenario and technological development.

In recent years, the power of fiber laser sources has continuously improved, from the initial kilowatt level to the ten-thousand-watt level or even higher. For example, Chuangxin Laser released the world’s first 160kW ultra-high-power industrial fiber laser source in 2024, setting a new global record. In addition, fiber laser sources with powers of 85kW, 50kW, 40kW, 30kW, and 20kW have also been launched one after another to meet the needs of different industrial applications.

The trend of miniaturization of fiber laser sources is also developing, which helps reduce energy consumption and weight and is easier to integrate into various industrial production processes. For example, the new generation of 3000W small-volume single-module lasers launched by JPT has reduced the volume and weight by 44% and 50%, respectively, compared with the old version. It is suitable for unique environments with limited space and weight. This miniaturization not only conforms to the development trend of green environmental protection but also improves processing efficiency and market competitiveness.

The power increase of fiber laser sources is mainly due to the breakthroughs in cutting-edge technologies such as high-power, high-brightness pump sources and large-mode-field special optical fibers. With the advancement of technology, the power of fiber laser sources has been continuously improved, meeting the needs of modern industry for high efficiency and environmental protection, especially in the metal cutting market. Fiber laser sources have become the mainstream technical route for industrial laser sources due to their high electro-optical conversion efficiency, good beam quality, and compact structure.

The development of high-power fiber laser sources improves cutting speed and efficiency. It also reduces the processing cost per meter of materials, promoting industrial upgrading and applications in high-end manufacturing. With the continuous advancement of technology, the power of fiber laser sources is expected to be further improved to meet a broader range of application needs.