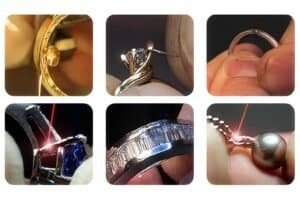

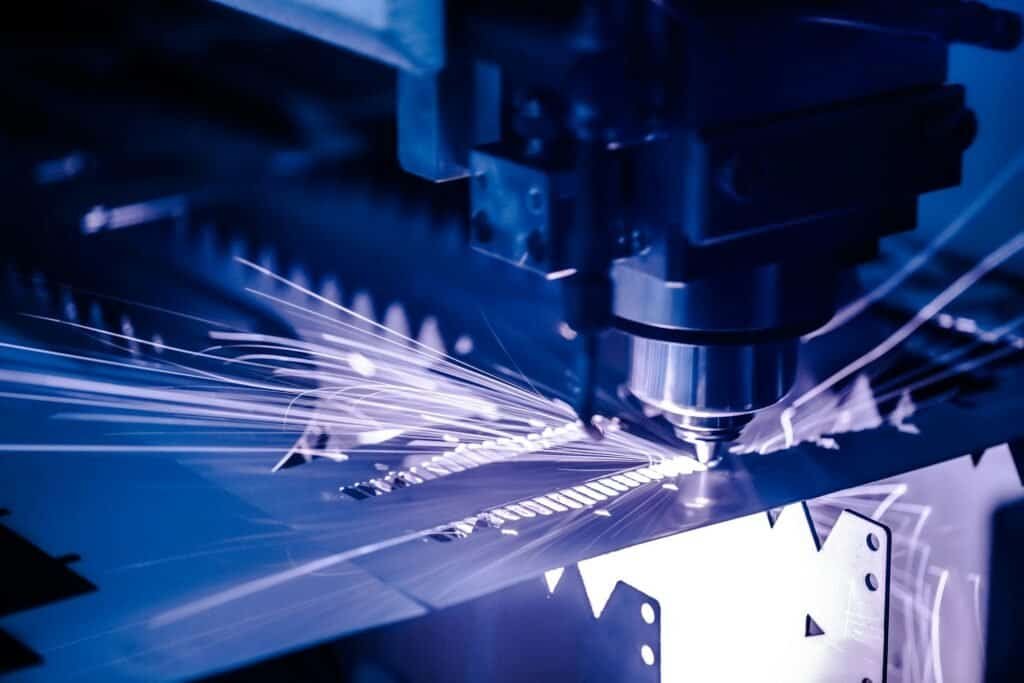

In the ever-evolving world of manufacturing, the pursuit of efficiency, precision and speed never ends. At the forefront of this pursuit are fibre laser cutting machines, marvels of modern engineering that have revolutionized how materials are cut and shaped. These machines are suitable for large-scale operations and support hobbyists and small businesses by providing a variety of applications, from cutting to engraving on metal materials such as copper and stainless steel.

As you drill down into choosing the fibre CNC laser cutting machine that best suits your needs, it’s critical to understand the factors that influence your choice, including the machine’s ability to handle a variety of metals such as steel, stainless steel, and aluminium. Its maintenance requirements and consistent performance ensure service life. This guide is designed to give you the knowledge you need to make informed decisions, covering everything from technical insights to budget considerations and after-sales support. Ensure your investment enhances your manufacturing capabilities and drives you to achieve unmatched precision and productivity.

CNC Metal Laser Cutting Machine Introduction

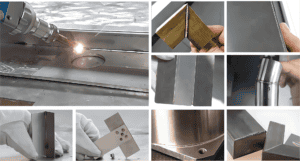

Fibre laser cutting technology has become a key innovation in the manufacturing industry, offering many advantages over traditional cutting methods. The core of the fibre laser cutting machine uses the laser beam generated by the fibre laser source to melt, burn, or vaporize materials with extremely high precision. The process is more than just cutting; it’s redefining the limits of accuracy and efficiency in material processing.

Understanding these machines begins with recognizing their importance in today’s manufacturing industry. They are not just tools but transformative tools that can significantly improve the quality and speed of production. CNC fibre laser cutting machine is mainly used to cut metal materials like stainless steel, carbon steel, alloy steel, aluminium plate, copper, titanium alloy, etc. These materials generally have high hardness and density, so how does the fibre laser cutting machine operate? It is a high-energy laser beam that cuts them quickly while maintaining the shape and size required for cutting. However, cutting aluminium, copper, titanium alloy, and other metal materials must cooperate with a specific gas or liquid to assist.

Factors to Consider When Choosing a CNC Metal Laser Cutting Machine

Material Thickness and Laser Power

1. Capability with Material Thickness: When selecting a fibre laser cutting machine, consider the machine’s ability to manufacture materials like stainless steel, aluminium, and carbon steel. The typical thickness range of 80% of your work should guide the required power for your application.

2. Laser Power Requirements: Higher laser power allows for a broader range of materials to be processed and provides more forgiveness in material and process errors. Thicker materials, in particular, require higher power levels for efficient piercing and cutting.

Machine Dynamics and Efficiency

1. Speed and Acceleration: Understand the rapid and cutting path speeds. It’s crucial to note whether manuIt’surerIt’sate the speed of each axis or specify simultaneous motion. Acceleration often impacts the overall performance more significantly than speed.

2. Deceleration and Cycle Time: The rate at which the machine can decelerate into and accelerate out of corners and tight arcs usually impacts cycle time more than maximum machine speed or laser power.

3. Pallet Changer Speed: The speed of the pallet changer is vital for high-production environments. Today’s fastest pallet changers are arTodToday’siven and can swap a pallet in under 10 seconds, significantly reducing downtime.

Cost and Operational Considerations

1. Table Size and Utilization: The right table size is essential to accommodate the largest workpieces and obtain materials at the lowest prices. If not fully utilized, oversized tables can lead to higher costs and inefficiencies.

2. Automation and Productivity: High production applications often, such as automated material handling systems, benefit from automation beyond the laser’s pallet changer, success systlaselaser’sontinuous and uninterrupted cutting, optimizing material handling, and reducing operator intervention.

3. Total Cost of Ownership: Consider the total cost of ownership, which includes maintenance, energy costs, and the availability of spare parts. The proximity of supplier service technicians is also crucial, as sophisticated technology makes hiccups inevitable.

Budgeting and Cost Analysis

Initial Investment and Operational Costs

1. Purchase Price Variability: The purchase price of a fibre laser cutting machine can vary significantly based on its features and specifications, from as low as $30,000 to upwards of $600,000.

Understanding this range is crucial for budgeting accurately.

2. Operational Cost Factors: Daily operational costs vary, with entry-level machines costing approximately $15-$30 per hour, while industrial-grade machines may run $100-$200 per hour. This includes energy consumption, maintenance, and consumables.

Long-Term Financial Considerations

1. Total Cost of Ownership: Beyond the initial purchase, the total cost of ownership includes storage, material costs, and staffing. This comprehensive understanding helps in planning long-term budgets and financial forecasts.

2. Quality and Durability Impact: Investing in a higher-quality and more durable machine may cost more upfront. However, it can lead to lower maintenance costs and reduced downtime, ultimately favourably affecting the cost per part.

Choosing the Right Machine for Cost Efficiency

1. Assessing Machine Value: Evaluate the overall value of the machine by considering its capabilities, performance, durability, and long-term cost of ownership. This assessment helps choose a machine that fits the budget and provides the best return on investment.

2. Impact of Machine Limitations: Be wary of cheaper machines as they may lead to increased downtime and higher maintenance and per-part costs, which could inflate long-term expenses.

After-Sales Support and Maintenance

Reliable After-Sales Support

1. Technical Support and Training: It is crucial to ensure you can operate your fibre laser cutting machine effectively if technical support is readily available to guide and assist you in mastering the operations of your machine.

2. Regular Follow-Ups: Regular follow-ups are conducted to optimize machine performance; a proactive approach helps maintain your machine’s efficiency.

3. Professional Assistance: In case of any operational issues, manufacturers provide prompt, professional assistance to resolve problems, ensuring high customer satisfaction.

Maintenance and Upkeep

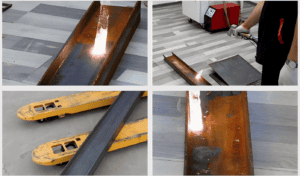

1. Preventative Maintenance: Scheduled preventive maintenance services are essential. They help identify and add essential issues before they escalate into major problems, thus extending the life and performance of your machine.

2. Cleaning and Maintenance: The torch, drive system, and slats should be regularly cleaned. This not only increases the longevity of the machine but also ensures that it lasts.res optimal cutting performance and minimizes downtime.

3. Cooling System Checks: Regular checks of the cooling system components, including coolers, coolant levels, filters, and fans, are necessary to maintain proper cooling and efficient operation.

Repair Services and Parts Availability

1. Efficient Repair Services: Quick and efficient repair services are vital. They minimize downtime and provide timely assistance in case of unexpected breakdowns, ensuring that your operations are not significantly disrupted.

2. Parts Availability: DAG offers independent after-sales service and parts for machines, even those purchased from other suppliers. This includes free consultation and professional solutions for machine upgrades or business expansions.

3. Lifelong Service Commitment: DAG is committed to providing lifelong after-sales service to each customer, reflecting high loyalty and responsibility towards users.

Frequently Asked Questions

- What factors should be considered when choosing a fibre laser cutting machine?

When selecting a fibre laser cutting machine, consider the following key aspects: work or bed size, i.e., the size of the table used to cut the metal; laser source; cutting; and warranty and service options provided by the manufacturer.

2. How much does a 6,000-watt fibre laser cutting machine cost?

A 6,000-watt fibre laser cutting machine typically costs about $30,000 each, but pricing may vary based on location and seller.

3. What is the cutting capacity of the 1000W fibre laser cutting machine?

A 1000W fibre laser cutting machine can generally cut carbon steel plates up to 10mm thick. Cutting stainless steel can be more challenging. If thicker materials need to be cut, edge quality and cutting speed may be affected.

4. How do you determine the power required for a fibre laser cutting machine?

The wattage required for a fibre laser cutter depends on the thickness and type of material you plan to cut. Higher-powered machines can handle thicker, denser materials but may have higher costs and greater operational complexity.