Are you looking for laser tube cutting services near you? Check out the best automatic laser tube cutting machines (with CNC controllers) for all metal tube types. Buy the right tube laser cutting machine to start or grow your metal fabrication business; make more money!

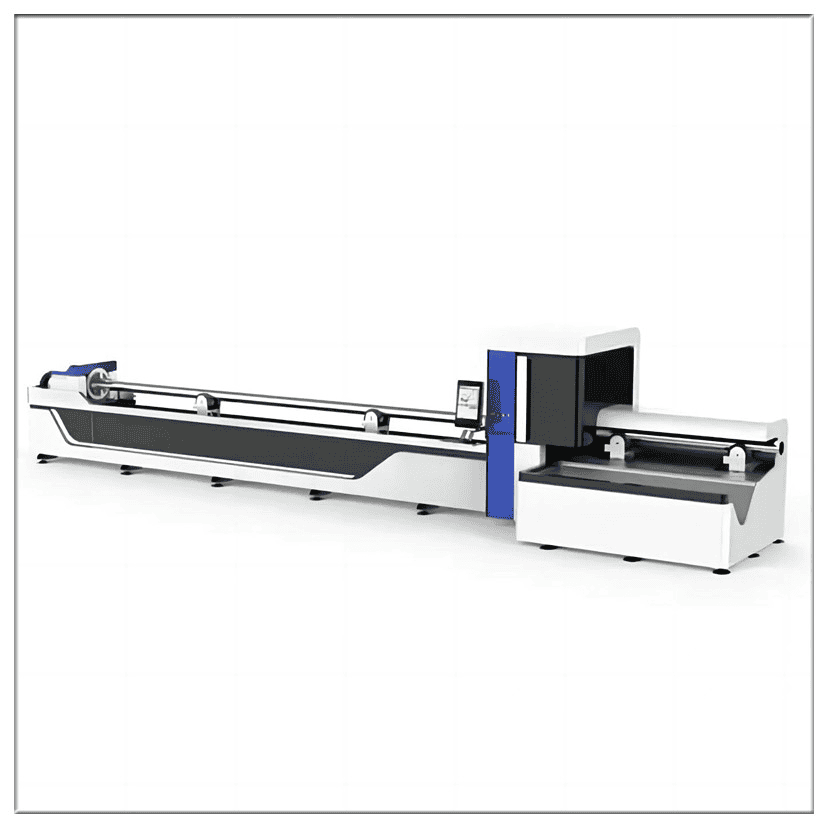

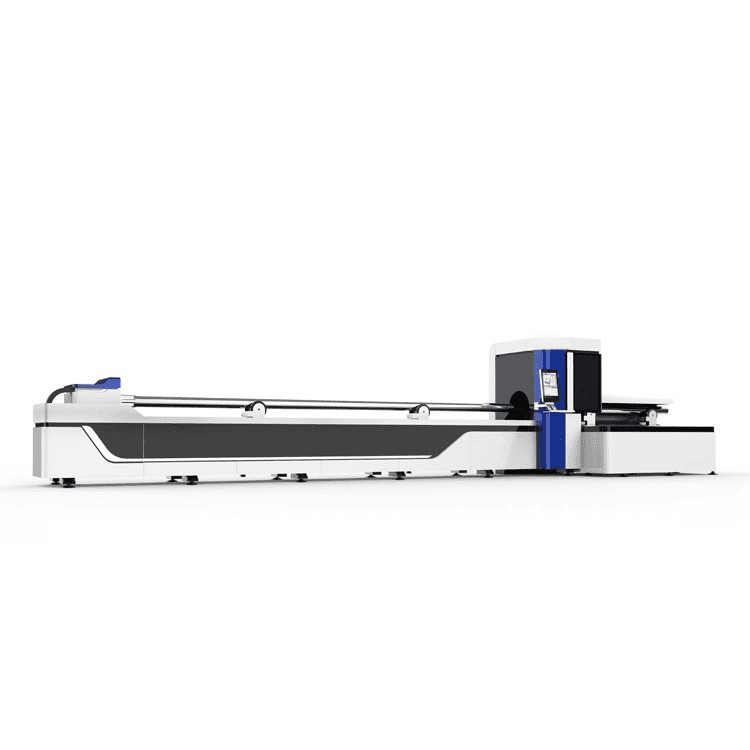

The fiber laser power of the DG series laser tube cutting machine ranges from 1000W to 6000W. It can accurately and quickly cut square, round, rectangular, and circular tubes and even unique metal wires.

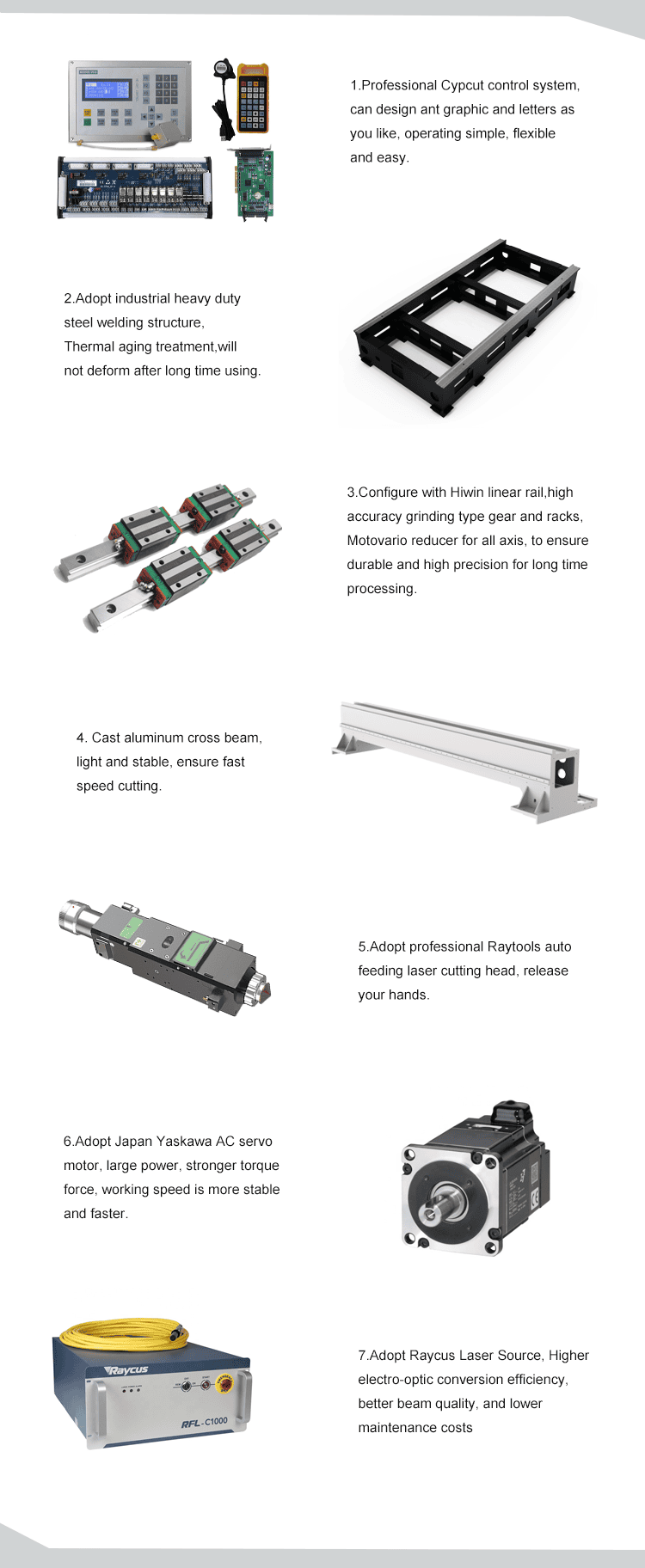

It is a powerful laser source produced by well-known companies such as Raycus, IPG, MAX, RECI, and nLight. It uses cutting-edge CNC technology. Its simple setup and easy-to-use interface allow operators to program shapes, contours and profiles easily, increasing productivity and reducing downtime.

What is a CNC Metal Laser Tube Cutting Machine?

The CNC metal laser tube cutting machine is an automatic CNC tube cutting system. Compared with traditional cutting, laser tube cutting has good flexibility and does not require mould opening, significantly saving new product development time. It has fast cutting speed and high precision. The tube laser cutting machine can realize the precision cutting of opening, cutting, intersection lines and various special-shaped complex graphics that are difficult to achieve by conventional methods and can better meet the increasingly high cutting process requirements.

Product Parameter

| Machine model | DG-6000T | |||

| Tube cutting working area | Φ20-Φ200mm×6000mm/8000mm | |||

| Laser source | Raycus, MAX, IPG,nLight, RECI (optional) | |||

| Laser power | 1000W/2000W/3000W | |||

| Cutting thickness | Power | Stainless Steel | Carbon Steel | Copper/Aluminum |

| 1000W | 0.2-5mm | 0.2-11mm | 0.2-3mm | |

| 2000W | 0.2-7mm | 0.2-15mm | 0.2-4mm | |

| 3000W | 0.2-9mm | 0.2-18mm | 0.2-5mm | |

| X.Y positioning accuracy | ±0.02mm | |||

| Min cutting line width | 0.02mm | |||

| Max cutting speed | 80m/min | |||

| Max moving speed | 60m/min | |||

| Voltage requirements | 380V,50Hz/60Hz | |||

| Net weight | 4500Kg | |||

DG-P6350

Product Parameter

| Model Number | DG-P6350 |

| Laser source | Raycus/MAX/IPG/nLight (optional) |

| Laser cutting head | Raytools/WSX |

| Output power of laser source | 1000W-6000W (optional) |

| Marking range | Φ30~Φ350mm×6000mm |

| Pipeload-bearing | 750kg |

| Max positioning speed | 70m/min |

| X.Y axis max acceleration speed | 1.8G |

| Control system | Cpycut |

| Power requirement | Yaskawa |

| Transmission | Double Drive Gear Rack |

| Guide rail | Taiwan Hiwin Guide Rail |

| Electricity demand | 380V 50HZ |

| Appearance size | 11500×2350×2500(mm) |

| Machine weight | 4T |

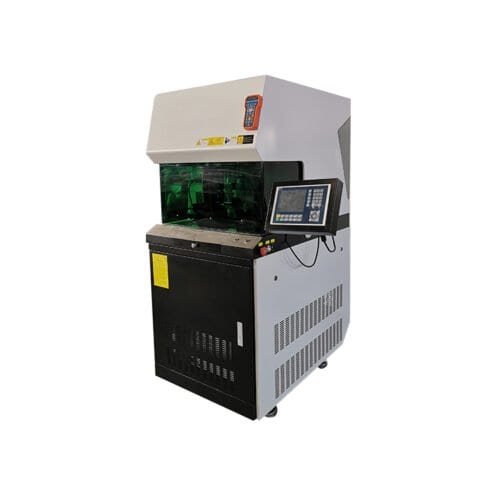

DG-CW500/1000/1500CTAT

Product Parameter

| Modele | DG-CW500/1000/1500CTAT |

| Suitable Diameter | 15-42/15-70/15-90/15-120/15-150mm |

| Laser source | Raycus/MAX/IPG/nLight (optional) |

| Laser Power | 500W/1000W/1500W |

| Wave Length of Laser | 1070nm±5nm |

| Laser Mode | Single Mode |

| Photoelectric Conversion Efficiency | 0.3 |

| Working Mode | Continuous |

| Power Regulation Range | 5-95% |

| Power Instability | ≤2% |

| Core Diameter of Transmission Optical Fiber | 25um-50um |

| Optical Fiber Length | 10m |

| Cooling Type | Water Cooling |

| Water Chiller Modele | C500/C1000/C1500 Double temperature anddouble circulation water chiller |

| Cooling Water Temperature | 20-25℃ |

| Power Source | AC220V±10% AC380V±10%,50/60Hz |

| Working Environment Temperature | 10~35℃ |

| Working Environment Humidity | ≤95% |

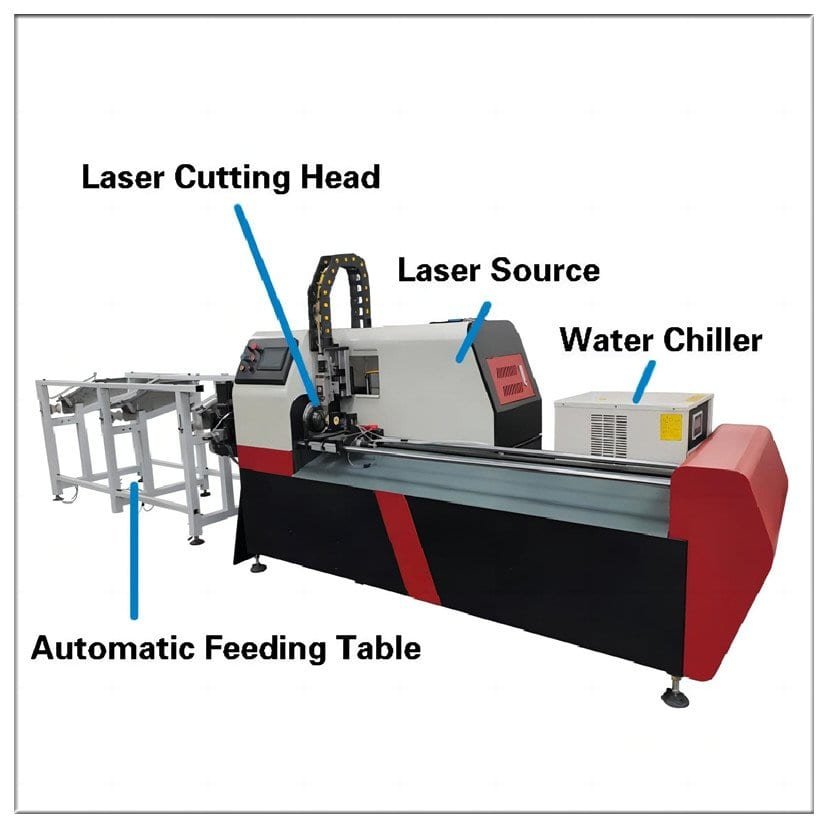

Accessories

Working Principle of Laser Tube Cutting Machine

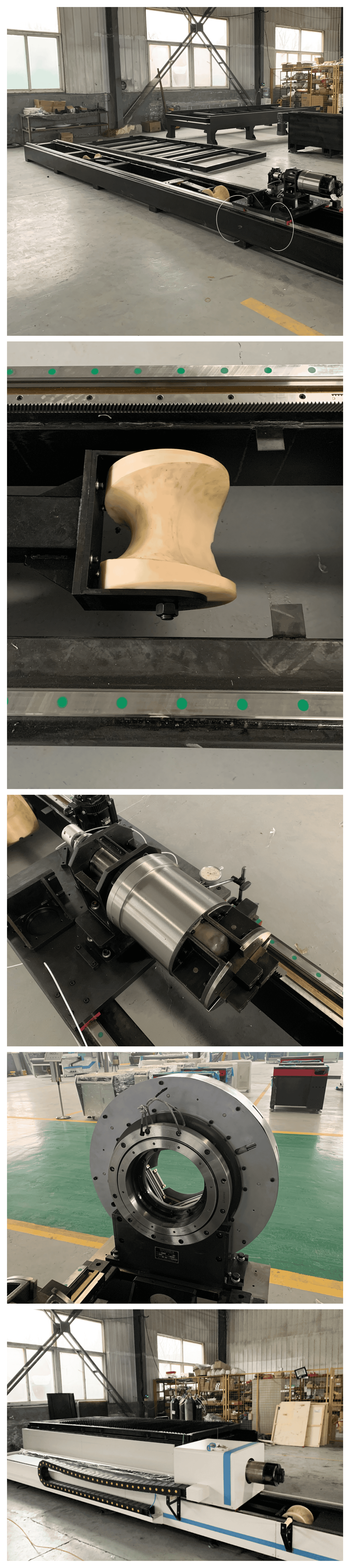

The laser tube cutting machine uses a focused high-power density laser beam to irradiate the workpiece, causing the irradiated material to melt, vaporize, ablate, or reach the ignition point quickly. A high-speed airflow coaxial with the beam blows away the molten material, cooperating with the motion mechanical system to achieve cutting of the workpiece.

Details

Advantages of Metal Laser Tube Cutting Machine

1. It can cut multiple cylindrical intersecting line holes of different directions and diameters on various metal thin-walled tubes, meeting the conditions of the eccentric and non-eccentric vertical intersection of the branch and main pipe axes.

2. It can cut the end of the cylindrical intersecting line at the end of the branch pipe, meeting the conditions of eccentric and non-eccentric vertical intersection and oblique intersection of the branch pipe axis and the central pipe axis.

3. It can cut the oblique end face at the end of various metal thin-walled tubes.

4. It can cut the end of the branch pipe intersecting line that intersects with the annular main pipe.

5. It can cut various metal thin-walled tubes’ variable angle groove surfaces.

6. It can cut square holes and waist-shaped holes on various metal thin-walled tubes.

7. It can cut various metal thin-walled tubes.

8. It can cut various graphics on the surface of various metal thin-walled tubes.

CNC Metal Laser Pipe & Tube Cutting Machine Application

Application industries: engineering machinery, locomotive manufacturing, oil pipelines, agricultural and forestry machinery, ladder guardrails, smart homes, fitness devices, metal homes, office desks and chairs, bus manufacturing and other industries.

Applicable pipe shape: This shape is suitable for cutting metal pipes and profiles, such as round pipes, rectangular pipes, special-shaped pipes, elliptical pipes, OB pipes, angle irons, channel steels, etc., and pipes of different materials and specifications.

What is the price of a CNC metal laser tube cutting machine?

The cost of a laser tube cutting machine includes a laser generator, fiber laser cutting head, CNC system, servo motor, rack and pinion, reducer, bed frame, beam, chiller, and air compressor. Depending on the wall thickness, length, cutting accuracy, and speed requirements of the tube you are processing, choosing different brands and accessories of different specifications will lead to differences in cost and price.

DAG offers CNC metal laser tube cutting machines at prices ranging from $20,000 ~ $60,000. Freight, on-site guidance and training services are charged separately. If needed, our engineers provide on-site guidance and training services at your local site. We require your assistance with visa procedures and prepayment of travel and accommodation expenses before dispatch and during service. Training time: 3 ~5 days.

Reviews

There are no reviews yet.