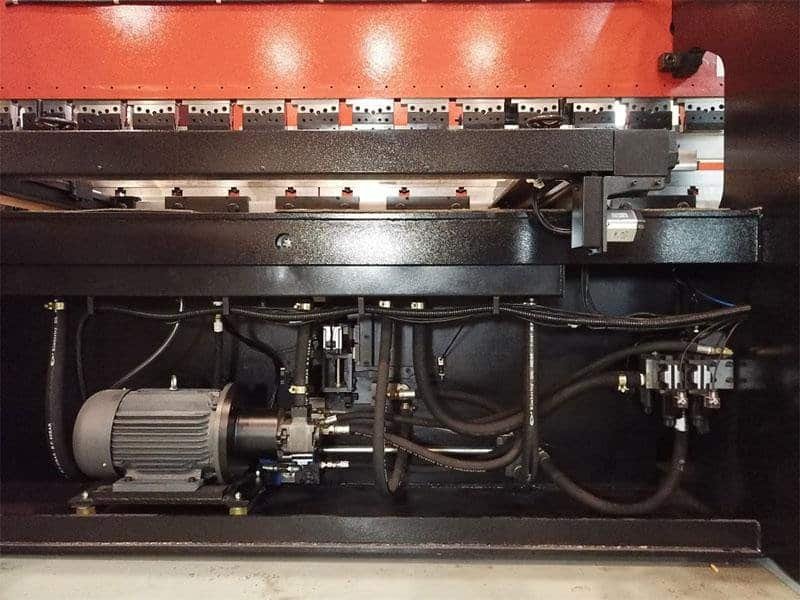

The DG series top-acting electro-hydraulic servo CNC bending machine has an oil-electric hybrid drive system and pump control synchronization control technology with higher precision and energy-saving effects. Higher precision, energy-saving effect, aster speed, high efficiency. It can be suitable for all kinds of workpieces for high accuracy, fast bending processing, higher parameters, and configuration design, and it is ideal for high-end customer demand.

.png.webp)

Product Parameter

Table 1

| Model | 11032 | 11040 | 13032 | 13040 | 17032 | 17040 |

| Nominal pressure (T) | 110 | 110 | 130 | 130 | 170 | 170 |

| Table length (mm) | 3200 | 4000 | 3200 | 4000 | 3200 | 4000 |

| Distance between columns (mm) | 2700 | 3400 | 2700 | 3400 | 2700 | 3400 |

| Throat Depth (mm) | 400 | 400 | 400 | 400 | 400 | 400 |

| Slider Stroke (mm) | 200 | 200 | 200 | 200 | 200 | 200 |

| Maximum opening height (mm) | 460 | 460 | 460 | 460 | 460 | 460 |

| fast-down speed (mm/s) | 230 ~ 170 | 230 ~ 170 | 230 ~ 170 | 230 ~ 170 | 230 ~ 170 | 230 ~ 170 |

| Bending speed (mm/s) | 20 ~ 10 | 20 ~ 10 | 20 ~ 10 | 20 ~ 10 | 20 ~ 10 | 20 ~ 10 |

| Return speed (mm/s) | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 |

| Motor power (KW) | 11 | 11 | 11 | 11 | 15 | 15 |

| Fuel tank capacity (L) | 350 | 350 | 400 | 400 | 450 | 450 |

| Total length of machine/Total arm span length (mm) | 3500/4200 | 4300/5000 | 3500/4200 | 4300/5000 | 3500/4200 | 4300/5000 |

| Total height of machine (mm) | 2650 | 2700 | 2700 | 2700 | 2750 | 2750 |

| Total width of the machine (mm) | 1500 | 1500 | 1500 | 1500 | 1550 | 1550 |

Table 2

| Model | 20032 | 22040 | 22060 | 25032 | 25040 | 25060 | 32032 | 32040 |

| Nominal pressure (T) | 200 | 220 | 220 | 250 | 250 | 250 | 320 | 320 |

| Table length (mm) | 3200 | 4000 | 6000 | 3200 | 4000 | 6000 | 3200 | 4000 |

| Distance between columns (mm) | 2700 | 3400 | 5000 | 2700 | 3400 | 5000 | 2700 | 3400 |

| Throat Depth (mm) | 400 | 400 | 400 | 450 | 450 | 450 | 450 | 450 |

| Slider Stroke (mm) | 200 | 200 | 200 | 250 | 250 | 250 | 250 | 250 |

| Maximum opening height (mm) | 460 | 460 | 460 | 500 | 500 | 500 | 500 | 500 |

| fast-down speed (mm/s) | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 | 170 ~ 120 |

| Bending speed (mm/s) | 10 ~ 8 | 10 ~ 8 | 10 ~ 8 | 10 ~ 8 | 10 ~ 8 | 10 ~ 8 | 10 ~ 8 | 10 ~ 8 |

| Return speed (mm/s) | 130 ~ 100 | 130 ~ 100 | 130 ~ 100 | 130 ~ 100 | 130 ~ 100 | 130 ~ 100 | 130 ~ 100 | 130 ~ 100 |

| Motor power (KW) | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 22 | 22 |

| Fuel tank capacity (L) | 500 | 500 | 500 | 550 | 550 | 550 | 600 | 600 |

| Total length of machine/Total arm span length (mm) | 3500/4200 | 4300/5000 | 6300/7000 | 3500/4200 | 4300/5000 | 6300/7000 | 3500/4200 | 4300/5000 |

| Total height of machine (mm) | 2780 | 2780 | 2900 | 3000 | 3000 | 3000 | 3150 | 3150 |

| Total width of the machine (mm) | 1550 | 1550 | 1750 | 1650 | 1650 | 1850 | 1900 | 1900 |

Detail

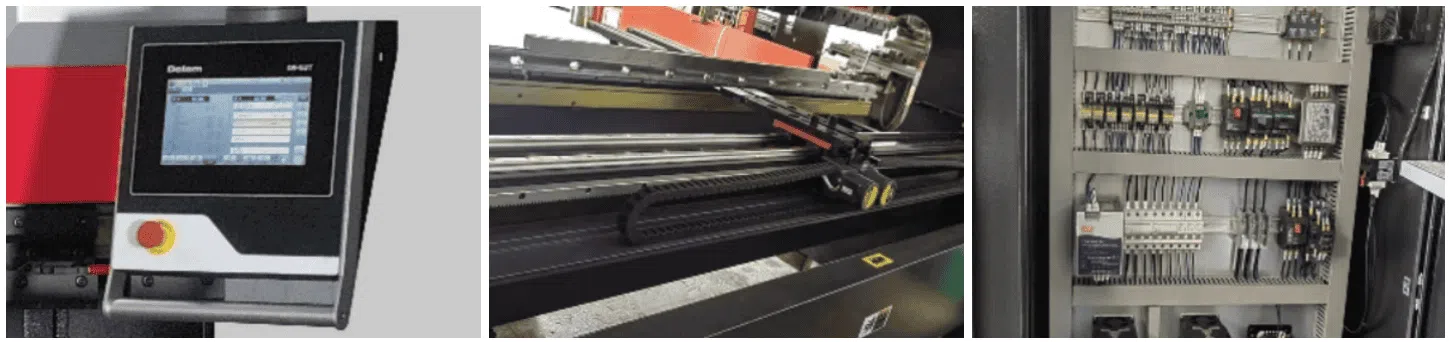

Electro-Hydraulic Servo CNC Bending Machine Control System Solutions

★ CNC System Options

DELEM / DA-53T Features

- “Hot-key” touch navigation

- 10.1″high resolution colour TFT 10.”

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Crowning control

- Tool/ material/ product library

- Servo and frequency inverter control

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- TandemLink(option)

- USB memory stick interfacing

- Profile-53TL offline software Profile-53TL

CYBELEC / CT12 Features

- 12-inch high-contrast color touch screen

- Up to 4+1 axes

- 2D Graphics Programming

- Multiple languages available

- 2D graphic display

- USB interface

- Standard axis 4+1 axis

- Tool / material/ product library

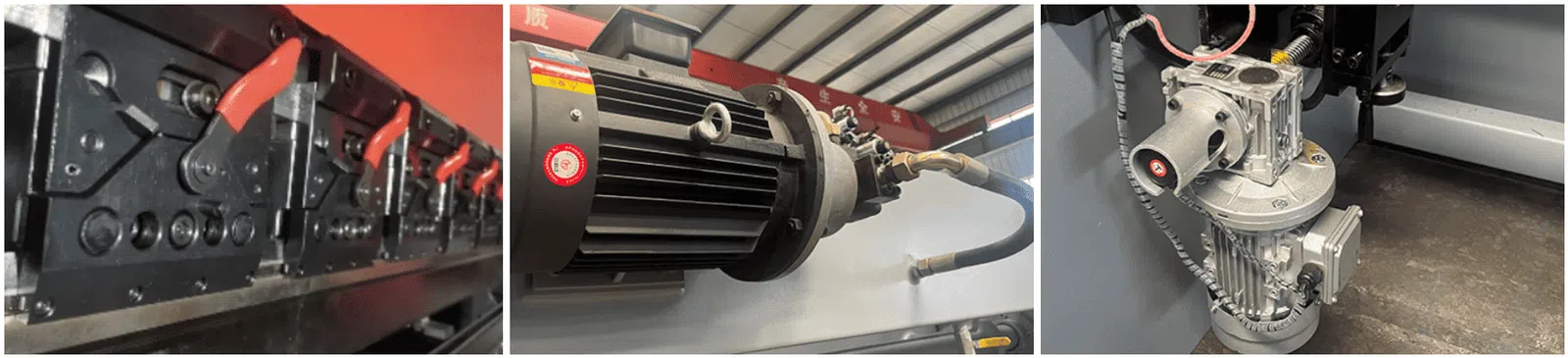

★ Safety Guards Options

DSP Laser Safety Protection With CE Standard

DSP Laser Safety Protection With International Standard

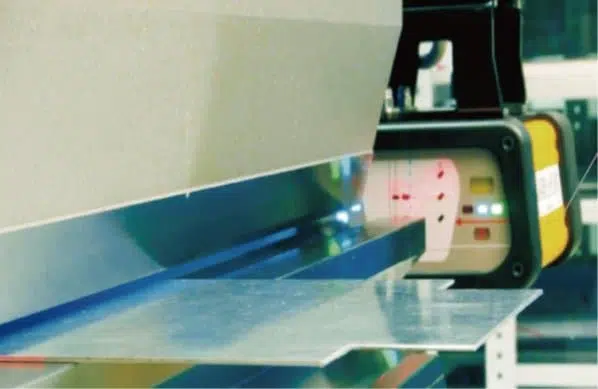

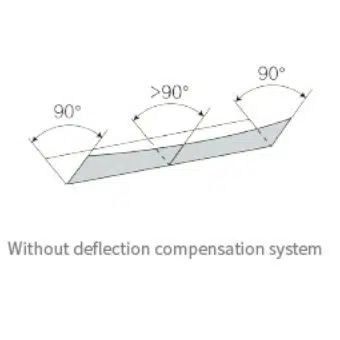

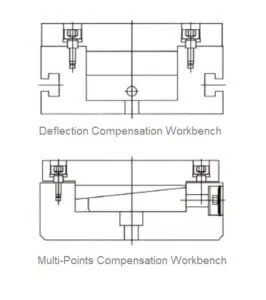

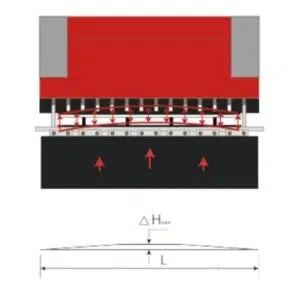

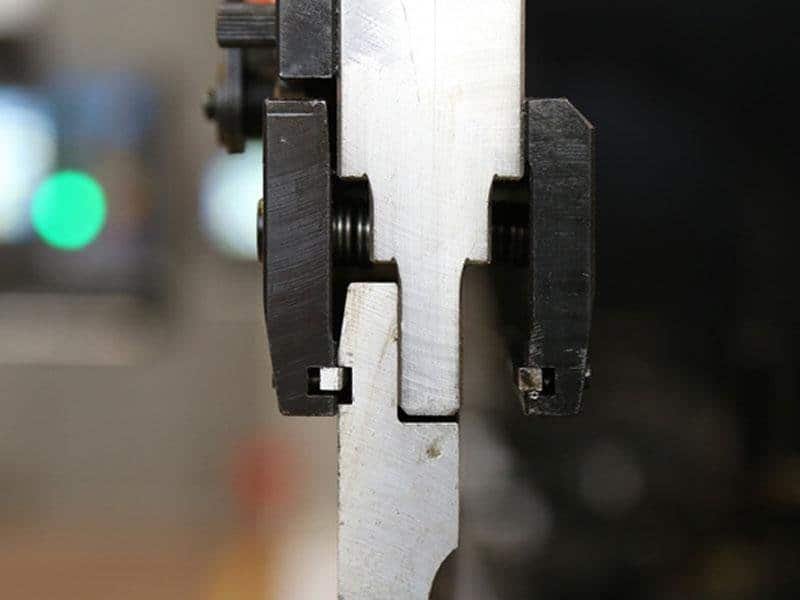

★ The Mechanical Deflection Compensation System

The mechanical deflection compensation system can compensate for the insufficient parts of the pressure of the entire length of the workbench so that Cam makes the workpieces with consistent accuracy. The mechanical deflection compensation consists of a set of convex wedges with bevels. The Convex wedge is designed based on the deflection curves of the upper and lower workbench finite element analysis. The CNC system is based on the working bending loading force (this force will cause the upper and lower workbench to produce pre-convex deformation). , or manually adjust it according to the operator’s actual deviation of the workpiece processing. Lt effectively compensates for the deflection deformation of the upper and lower workbenches and gets suitable bending workpieces.

Introduction to CNC Bending Machine

1. What is a CNC bending machine?

The CNC bending machine is modern metal processing equipment controlled by a computer program. Its main function is to bend metal sheets. The machine controls the operating system by manipulating programming software to accurately control the motion trajectory and speed of the machine tool cylinder, thereby achieving high-precision, high-efficiency, and highly automated production.

2. The difference between a CNC bending machine and an ordinary bending machine

Compared with traditional manual or semi-automatic bending machines, CNC bending machines have the following advantages:

● High precision: Because a computer program controls it, the bending angle and size can achieve very high precision;

● The high degree of automation: only the correct program needs to be entered to achieve automated production without manual intervention;

● High production efficiency: Compared with bending production performed by other methods, CNC bending machines can quickly perform a large amount of production work.

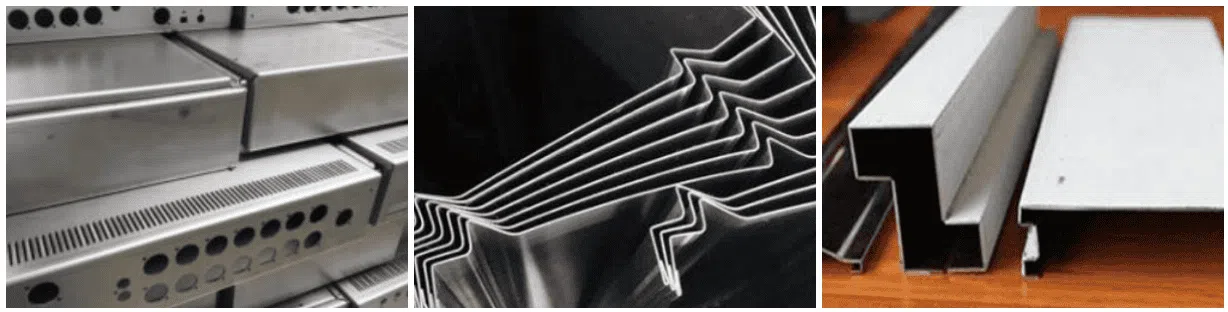

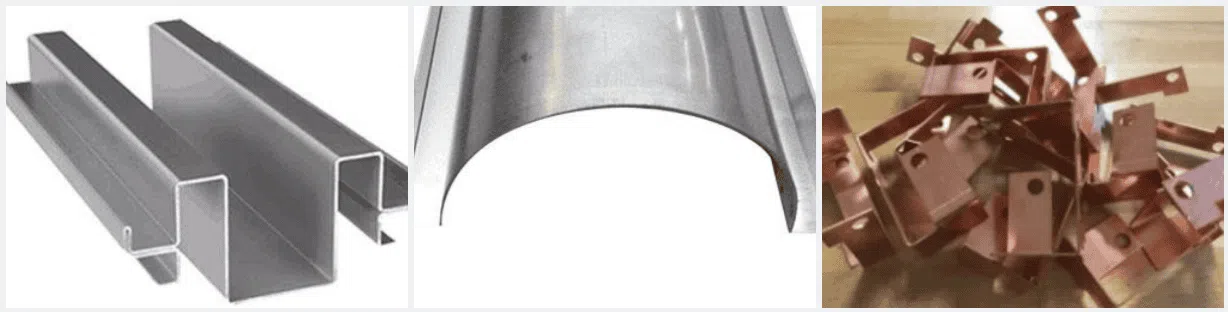

3. CNC bending machine application

CNC bending machines are widely used in various industries, such as construction, automobile manufacturing, home appliances, cabinets, and sheet metal processing. In these industries, CNC bending machines can produce parts of various specifications and shapes, which can be embedded into products with different size and shape requirements.

Things to Note When Buying A Metal Bending Machine

1. CNC bending workpiece

We first need to consider the length and width of the parts you will produce and choose a CNC bending machine that can complete the processing task with the smallest workbench and the highest quality performance. It is best to be precise, which saves costs and is technically applicable.

2. Tonnage selection of bending machine

Calculate the tonnage of the bending machine you need to purchase based on the material and thickness of the metal to be processed. (The tonnage here refers to the pressure of the bending machine rather than the weight of the CNC bending machine body)

3. CNC system

Whether there is computer control, automatic feedback, different processing speeds, different processing accuracy, and different processing efficiency are the key factors that determine the quality of a CNC bending machine.

4. Is the process fully automated?

Whether to choose an electro-hydraulic synchronous CNC bending machine or a torsion-axis synchronous bending machine is also a question that needs to be considered. The electro-hydraulic synchronous type bending machine can be more intelligent and fully automated, but the price is higher. The torsion-axis synchronous type bending machine The price is cheaper; whether it is a performance advantage or a price advantage is an important factor that you must consider when choosing a machine.

-500x500.png)

Reviews

There are no reviews yet.