What is a Small jewelry laser spot welding machine?

A small jewellery laser spot welding machine is professionally used for welding gold and silver jewellery in the jewellery industry, such as hole filling, spot welding sand holes, and repair. It has the advantages of high precision, low loss, and ultra-fast speed. It adopts laser deposition welding, considerable heat energy, and concentrated fixed-point welding technology. The surface heat is diffused to the inside through conduction. By controlling the width, energy, peak power, and repetition frequency of the laser pulse, the workpiece is melted to form a specific molten pool.

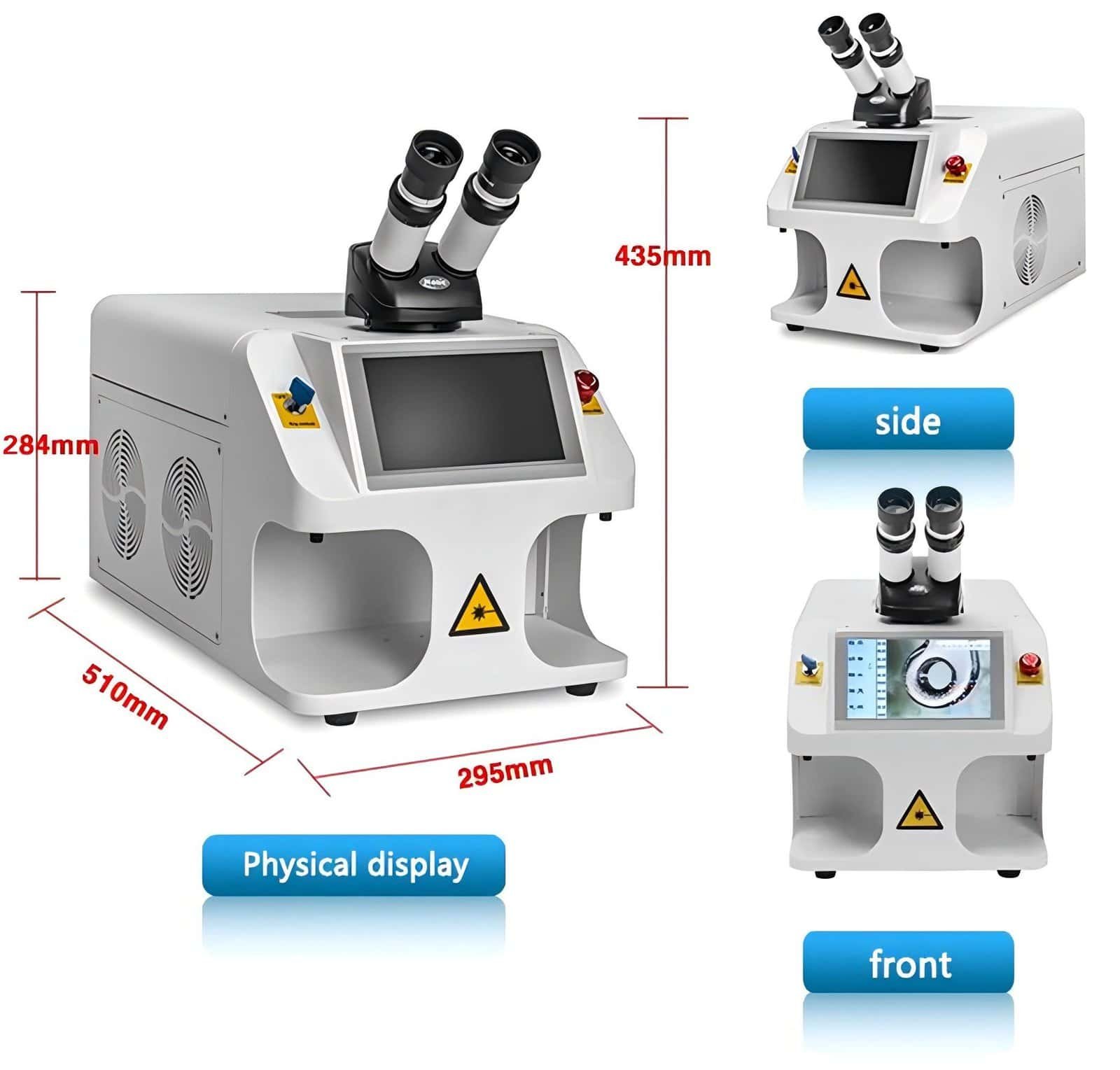

Small jewelry laser spot welding machine is suitable for shopping malls and can be placed directly on the counter. It is small, does not take up space, is easy to carry, and is simple to operate. It can be used in jewellery repair shops, watch repair shops, glasses repair shops, dental clinics, hardware repair shops, and electronic repair shops. It comes with a CCD microscope dual display system for easy user operation.

Product Specifications

| Product name | Small Jewelry Laser Spot Welding Machine |

| Laser type | YAG |

| Laser power | 60W80W100W150W Optional |

| Function | Welding and Repair |

| Cooling System | Air cooling |

| Processing material | stainless steel, gold, silver and other metals |

| Welding mode | Manual |

| Advantage | Easy Operate |

| After-sales Service Provided | Online Support |

Product Features

The small jewelry laser spot welding machine adopts an ergonomic and professional appearance design. It has a microscope observation system with a cross cursor and a high-speed electronic filter device to protect the operator’s eyes. The high-power beam expansion system obtains finer light spots to meet the needs of fine laser spot welding. The core component, “laser focusing cavity,” adopts a gold-plated reflective focusing cavity with more stable performance and longer service life, bringing users efficient and economical processing solutions. The machine is small and easy to carry, and the operation process is simple. The welding effect is good, the equipment is stable and reliable, and the failure rate is low.

Product Details

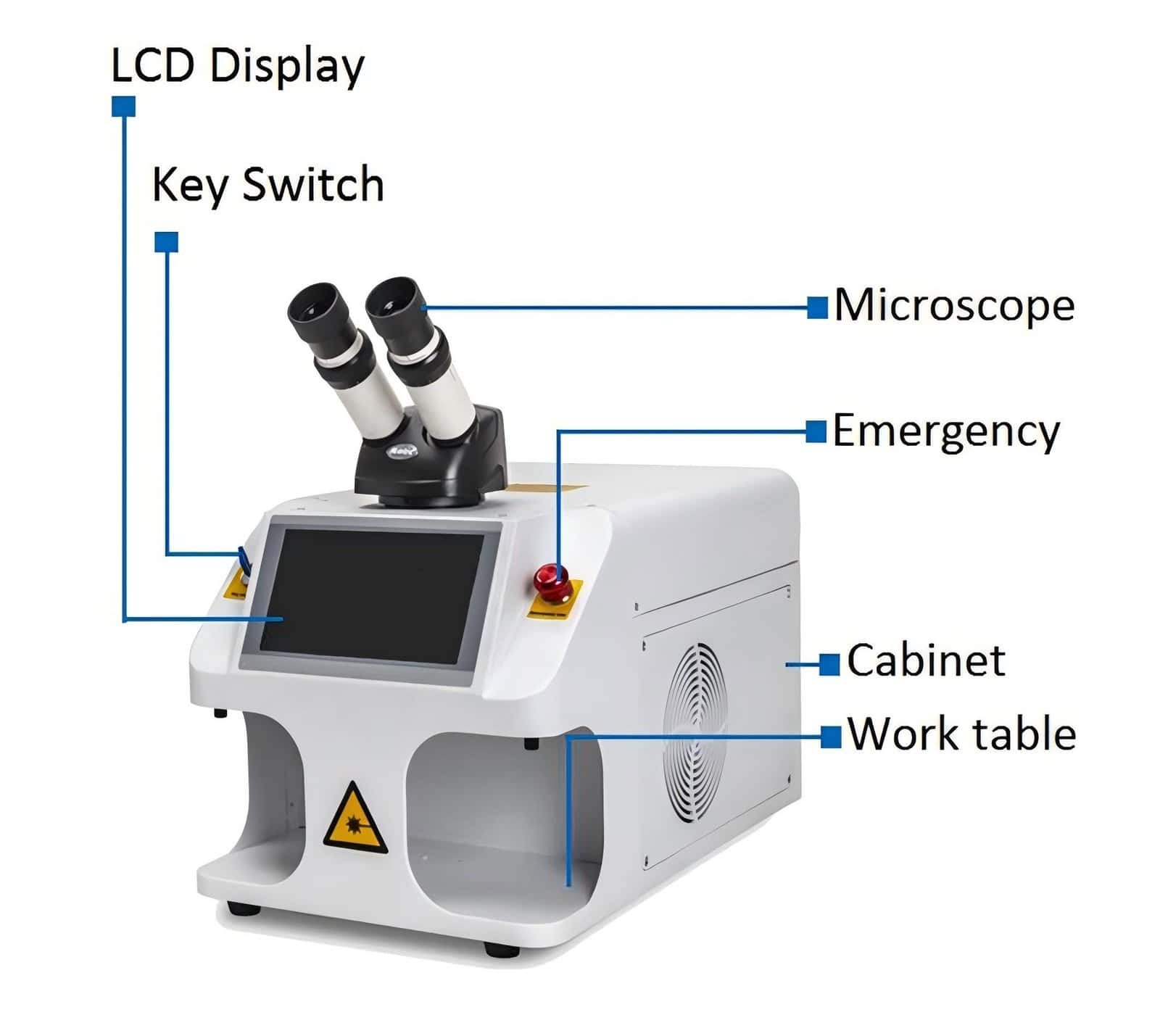

Microscope

Carefully observe the welding reaction of the sample.

Control Panel

The control screen only needs to adjust three parameters. It is convenient and has a simple operation you can use!

Workbench

Standard configuration with two warm colour temperature LEDlights, optional 2D lifting table.

Interface

Imported electronic interface components, such as standard AC 220Vvoltage, to maintain safe work.

Foot Switch

The external pedal controls the laser to work, click once, and emit light once.

Product Advantages

Unlike traditional welding methods, small jewelry laser spot welding machines show incomparable advantages. First, laser spot welding has exceptionally high precision. It can accurately locate and achieve welding of tiny areas, which is especially important for finely processing gold and silver jewelry. Secondly, the heat-affected zone of laser spot welding is small, and the thermal damage to the material is shallow, which maintains the original gloss and texture of the welding part, perfectly meeting the high-end quality requirements of gold and silver jewelry. Furthermore, the laser spot welding process is fast and efficient, significantly improving production efficiency and reducing production costs.

With their unique technical advantages, small jewelry laser spot welding machines have become a powerful tool for processing gold and silver jewelry. Through precise laser control and efficient welding technology, it not only improves the processing accuracy and efficiency of gold and silver jewelry, but also protects the original characteristics of the material, achieves high-quality and high-efficiency production, and provides strong support for the innovative development of the gold and silver jewelry industry.

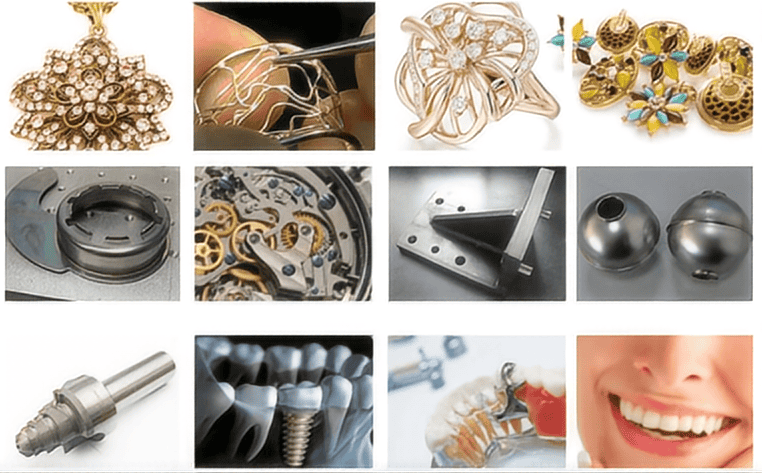

Product Application

It is widely used in precision casting and welding small hardware made of various metal materials, such as jewellery, dentures, watches, medical equipment, instrumentation, electronics, mechanical mould processing, automobiles, and other industries. It is especially suitable for welding holes in gold and silver jewellery, spot welding sand holes and repairing seams and claws of inlaid parts.

Other models

| Laser Power | 200W |

| Max Single Pulse Energy | 120J |

| Laser Wavelength | 1064nm |

| Pulse Frequency | ≤100Hz |

| Repeating Precision | ±0.1mm |

| Pulse width | ≤20ms |

| Spot Adjusting Range | 0.1-3.0mm |

| Power Consumption | 6KW |

| Viewing System | Microscope |

| Voltage | Single-Phase 220V/50HZ/20A |

| Cooling | Water Cooling |

| Laser Power | 60W80W100W200W(Optional) |

| Max Single Pulse Energy | 150J |

| Laser Wavelength | 1064nm |

| Pulse Frequency | ≤100Hz |

| Pulse Width | ≤20ms |

| Spot Adjustment Range | 0.1-3mm |

| Repeating Precision | ±0.1mm |

| Observation System | Microscope |

| Voltage | Single-Phase 220V/50HZ/20AVoltage |

| Overall Power | 6KW |

| Cooling Method | Water Cooling |

| Cabinet Shape Color | Custom or Standard |

| Cabinet Size | 1000*600*820 mm |

Service & Commitment

After-Sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality Control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM Service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms Of Payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document Support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.