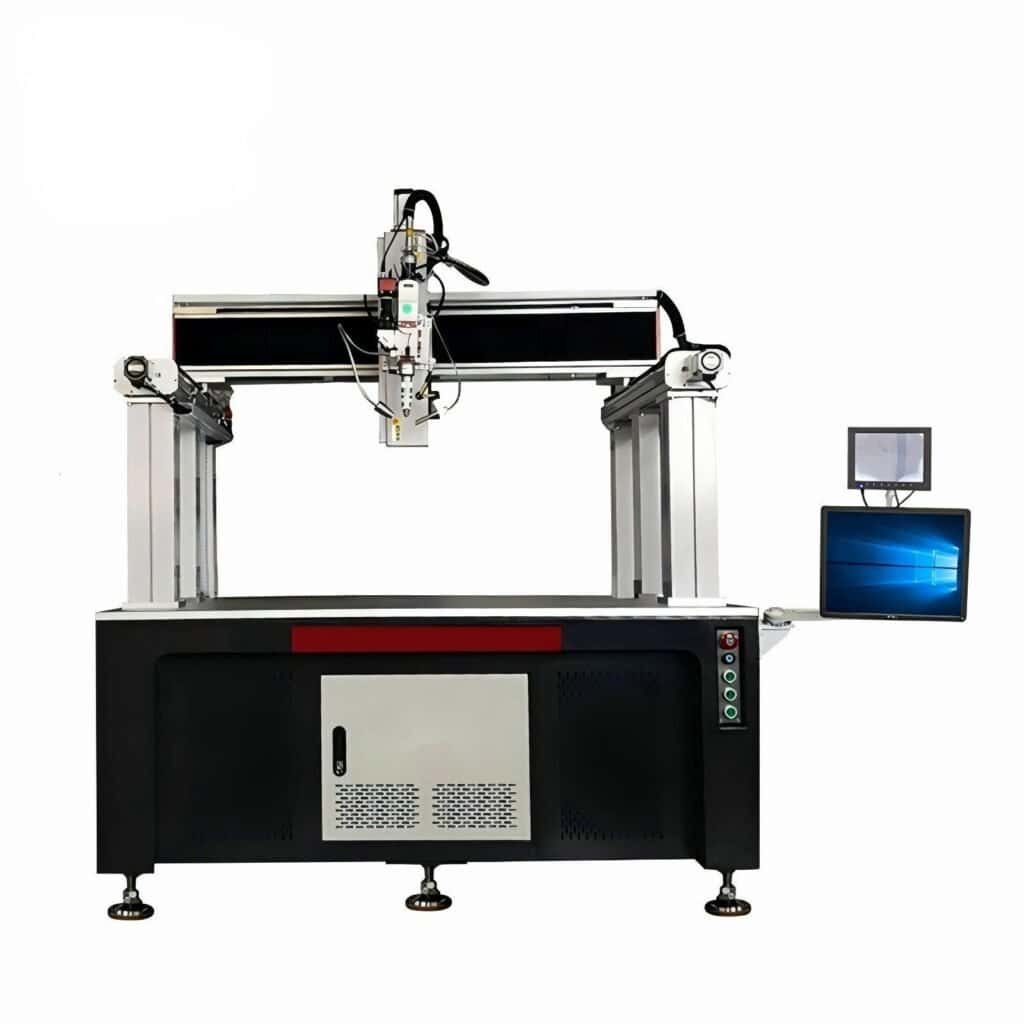

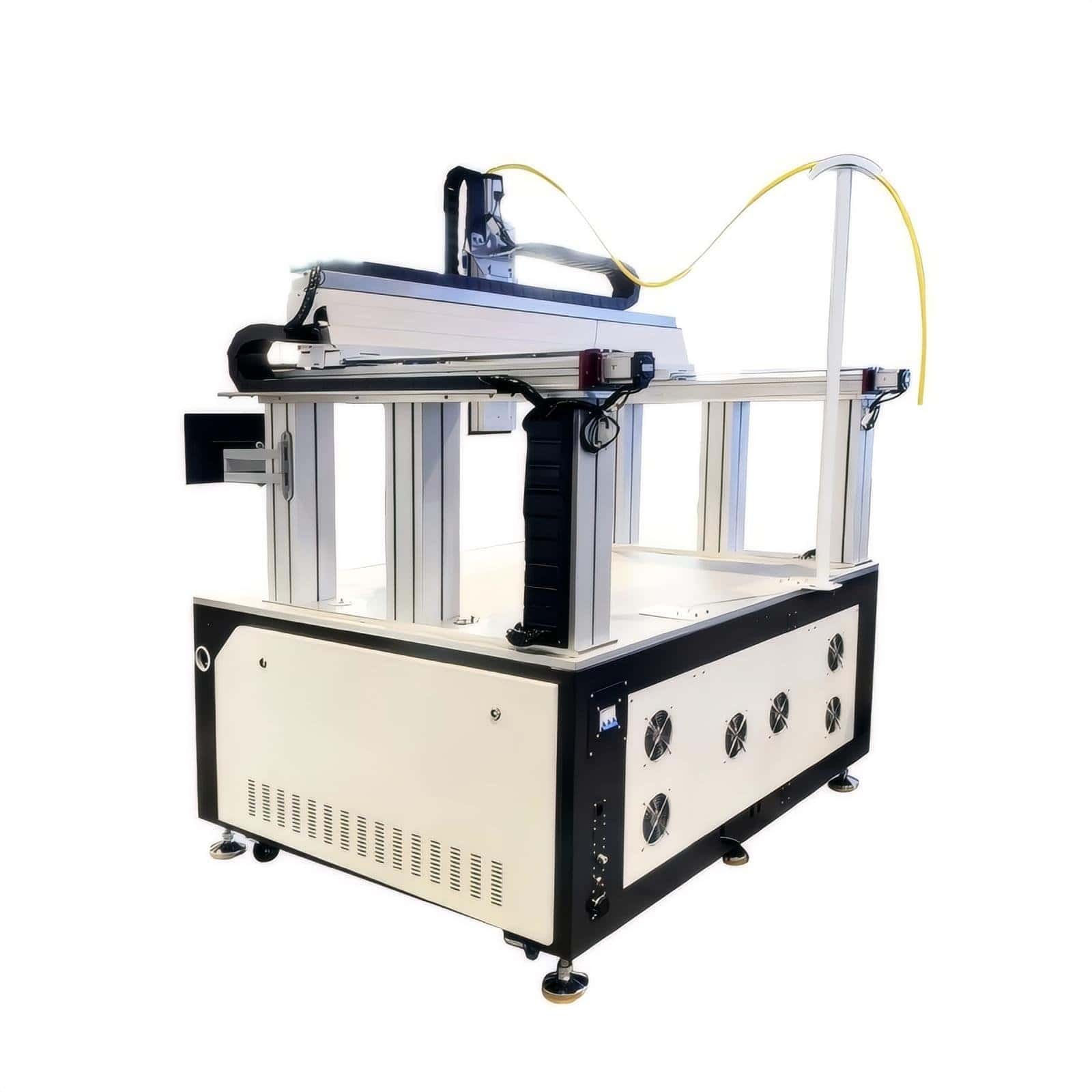

What is an automatic platform laser welding machine?

The automatic platform laser welding machine is a laser welding equipment professionally used in traditional hardware, new energy and other industries. It has the advantages of high peak power, good beam quality, fine spot, flexible installation, etc. The laser beam can achieve different spot shapes and process special-shaped spots simultaneously to meet various high-requirement welding effects, such as mixed welding, and achieve precise and efficient welding. The automatic platform welding machine adopts an integrated welding module welding + aiming combination design, visual CCD acquisition, integrated infrared sensor, accurate positioning, multi-axis servo welding workbench, high positioning accuracy, sensitive response, and anti-vibration design. It does not require manual movement of products and can weld automatically. Laser welding with a laser welding head can achieve spot welding, butt welding, lap welding, and sealing welding of thin-walled materials and precision parts.

Six advantages of DAG automatic platform laser welding machine

Service life of more than 30 years

A laser welding machine can last over 30 years or more than 120,000 hours under regular use.

Supports automated non-standard customization

It supports free proofing and strong grafting, can be customized according to different equipment, and can be installed on robots, XYZ multi-axis, other automated equipment, and assembly line equipment to achieve complex welding processes. It is easy to automate high-speed welding. It can also be digitally or computer-controlled.

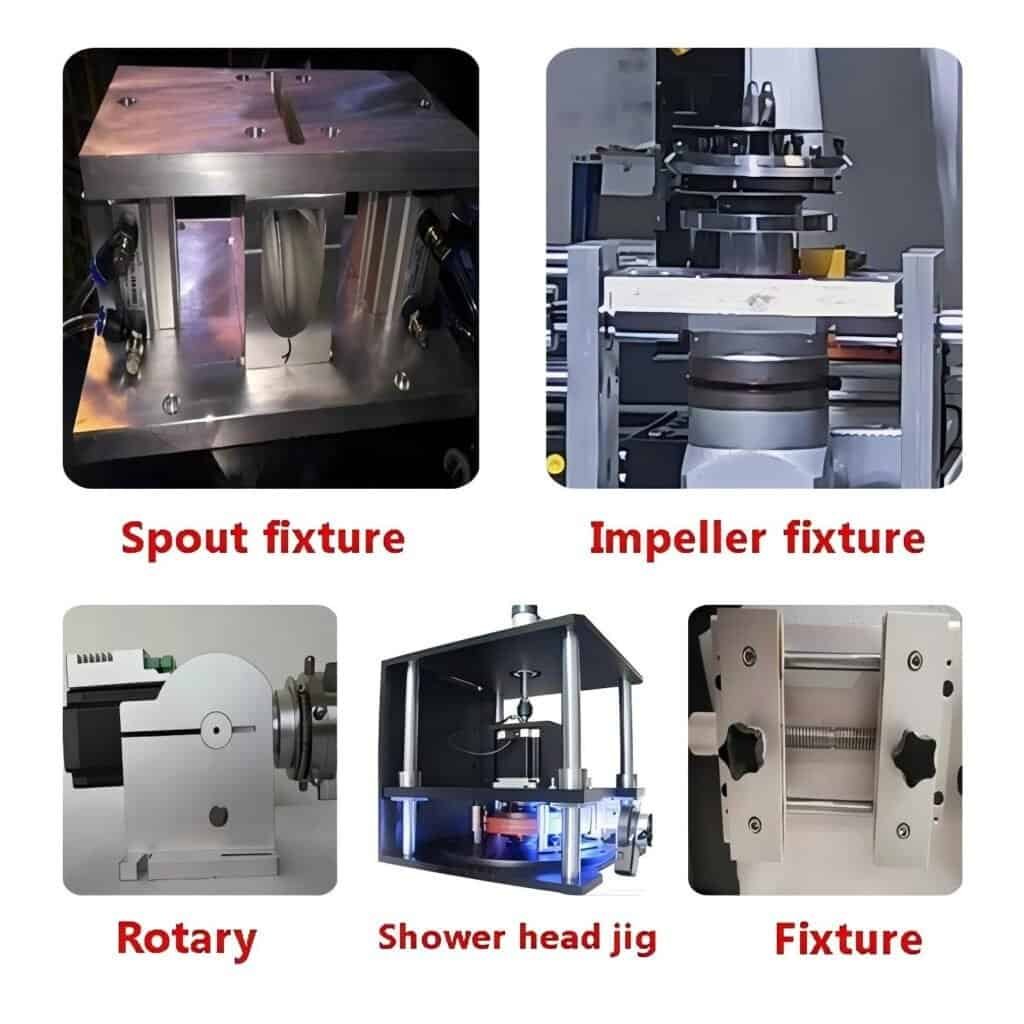

Customizable automated fixtures

They are combined with assembly lines, photoelectric sensors, pneumatic fixtures and other combinations for fully automatic processing to achieve mass production of products.

No deformation and high-precision

No tool grinding is required, no deformation in the heat-affected zone, and tiny parts can be processed.

Any angle and shape welding can be achieved.

Any angle welding can be achieved, and complex and irregular-shaped workpieces can be welded.

Wide range of welding materials

Stainless steel, carbon steel, aluminium, copper, alloys and other metal materials are applicable.

Product Parameters

| Product Name | Automatic Platform Laser Welding Machine |

| Laser Power | 1000W 1500W 2000W 3000W 4000W optional |

| Laser Source | Raycus IPG JPT Max optional |

| Welding Head | WSX Raytools optional |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cooling System | Water Cooling |

| Voltage | 380V/3-Phase/50Hz/40A/60A |

Product Accessories

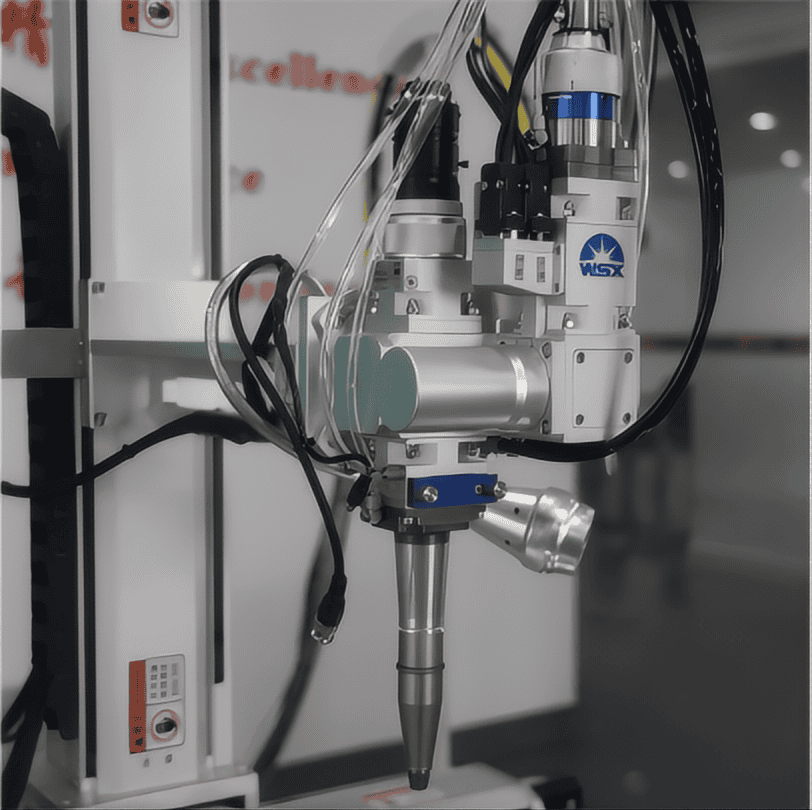

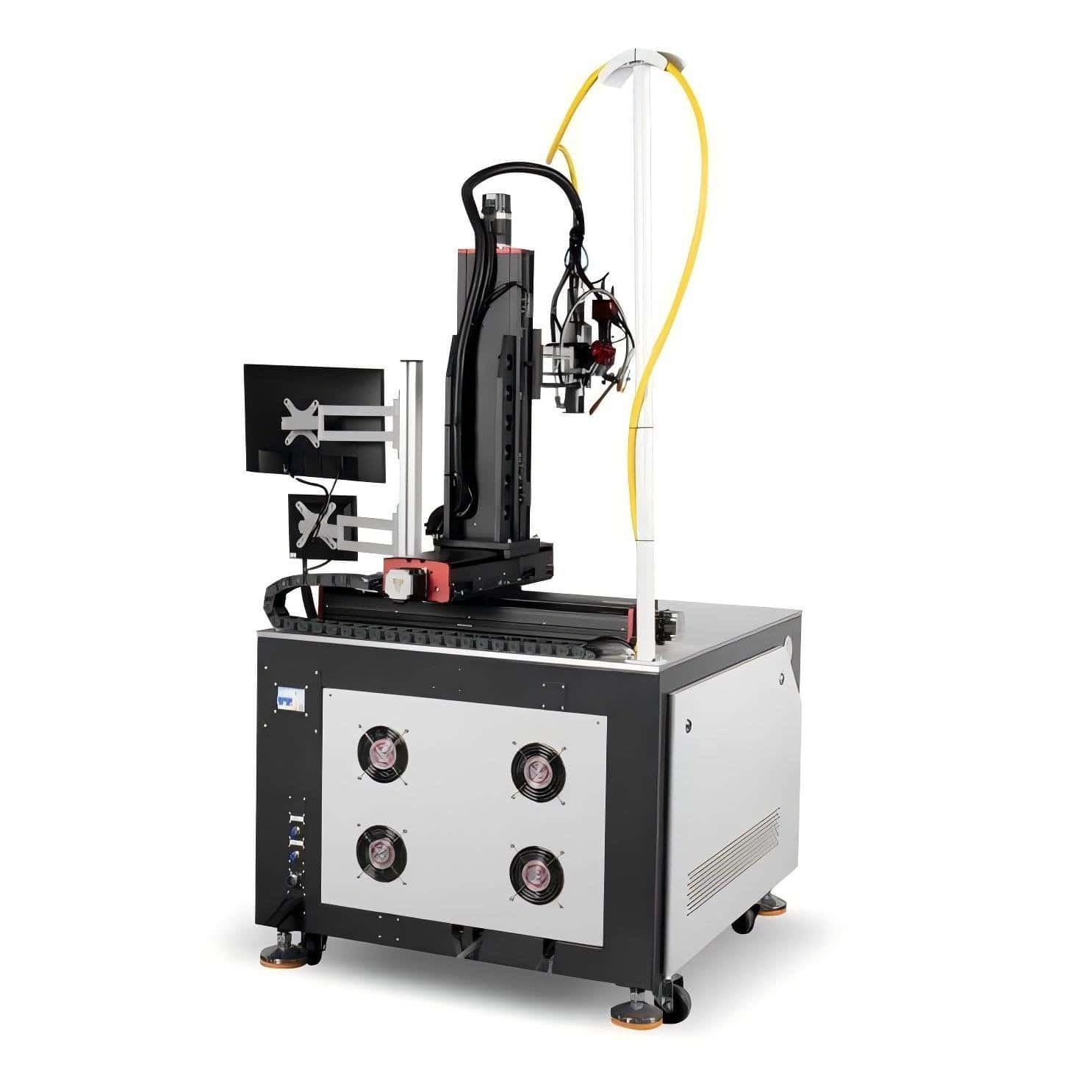

Laser Welding Head

Adopts Industrial Standard QBHConnector, which connects to fiber laser and provides standard fiber access. It has High welding precision, outstanding durability, and easy maintenance and adjustment.

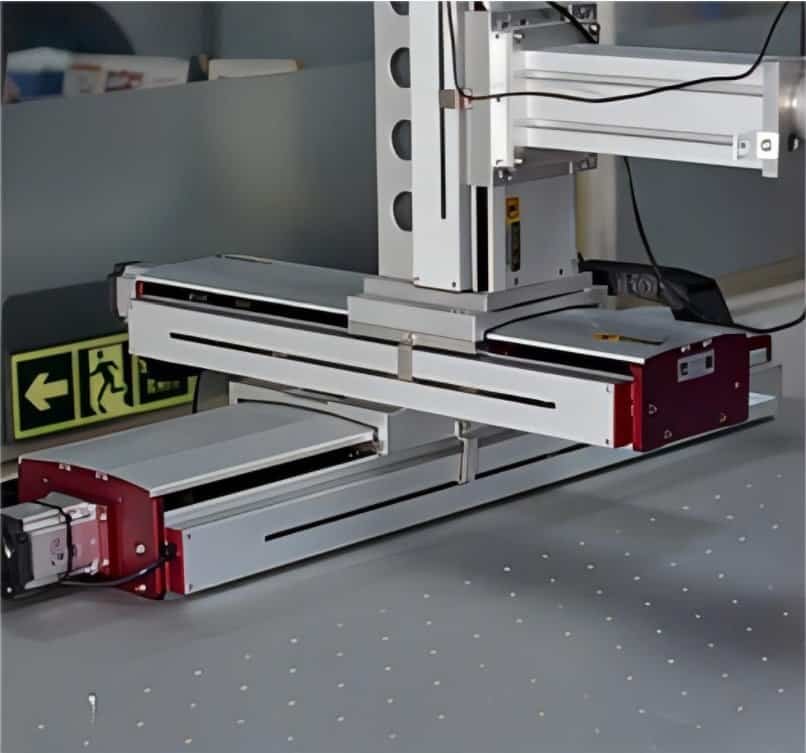

X.Y.Z Axis Guide Rail

With the function of moving up and down, it can weld irregular products. The Z-axis has a brake function.

CCD Camera Display

Display on a video display by connecting the device, Clearwelding point.

Laser Source

With the advanced fiber laser generator, we can achieve 200% higher efficiency, 100% sealability after welding, and 50% lower consumable costs compared to YAG lasers.

Water Chiller

Equipped with a 1.5P water chiller with a fast cooling effect, it supports continuous working.

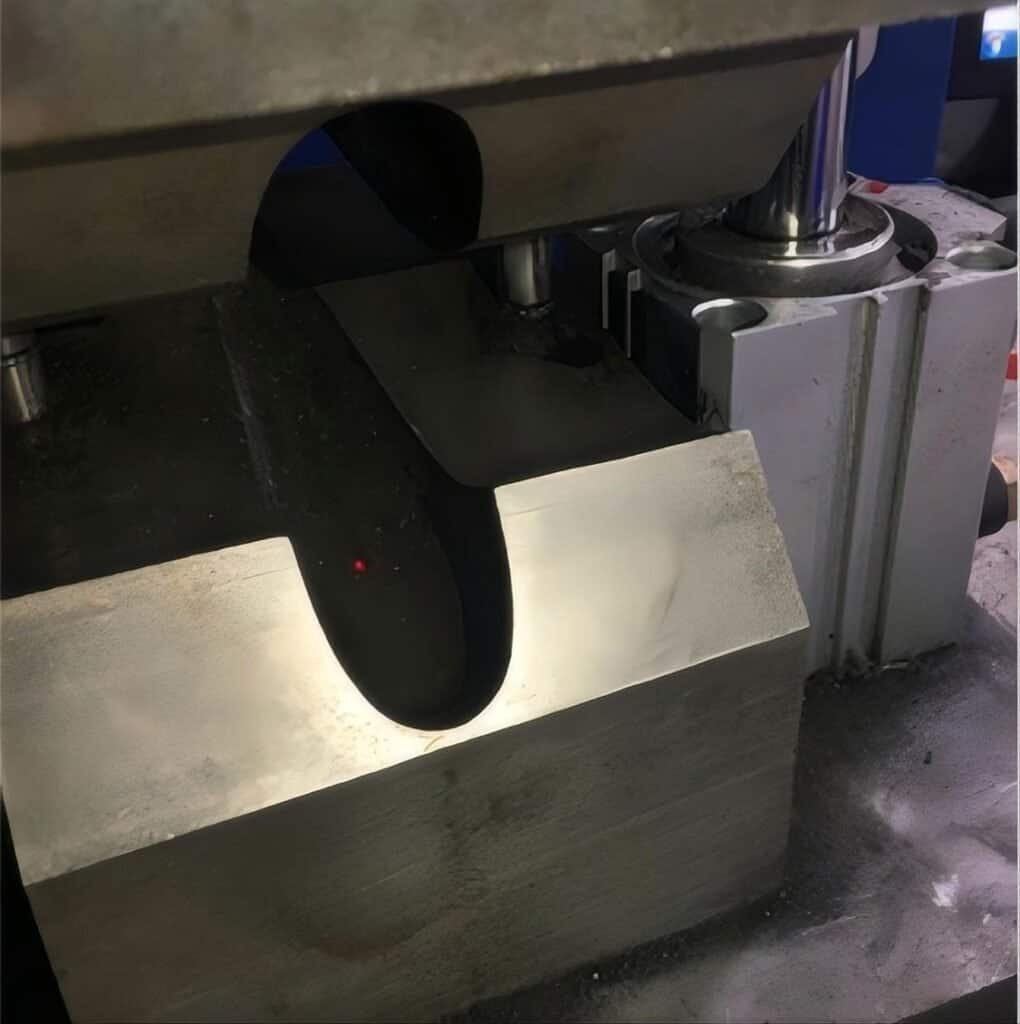

Customized Fixtures/Jigs

The above are the clamps we commonly use, which can weld different shapes, such as round tubes and square tubes. Different clamps can be customized according to different products. (Optional device)

Optimal configuration for kettle welding

Laser welding head

This laser welding head is suitable for the thickness of the kettle, with fast welding speed and competitive price.

Spout fixture

This fixture is copied according to the tamping die size of the spout itself. We suggest the customer give us the mould data to make it.

Nozzle fixture

This is a nozzle fixture for welding the nozzle teapot body, making it an automatic welding machine. It can be customized according to the client’s product and requirements.

Bottom fixture

This picture shows the kettle’s bottom before welding. We put the product on the fixture and then press the button to control the fixture so that it can start working.

Application Areas

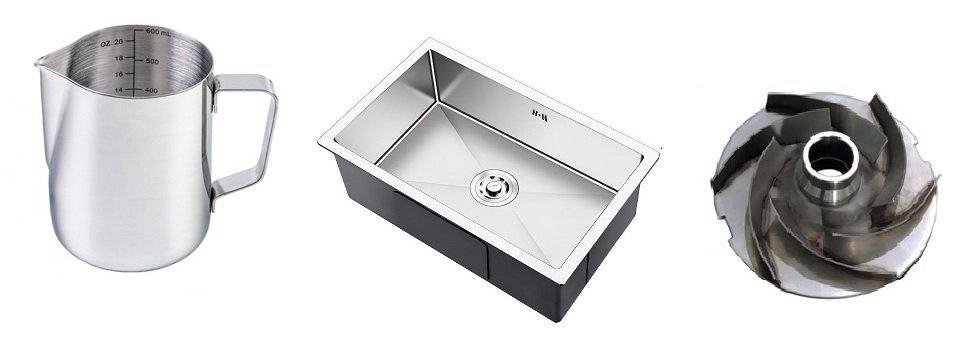

Bathroom industry: water pipe joints, reducers, tees, valves, shower heads, etc.

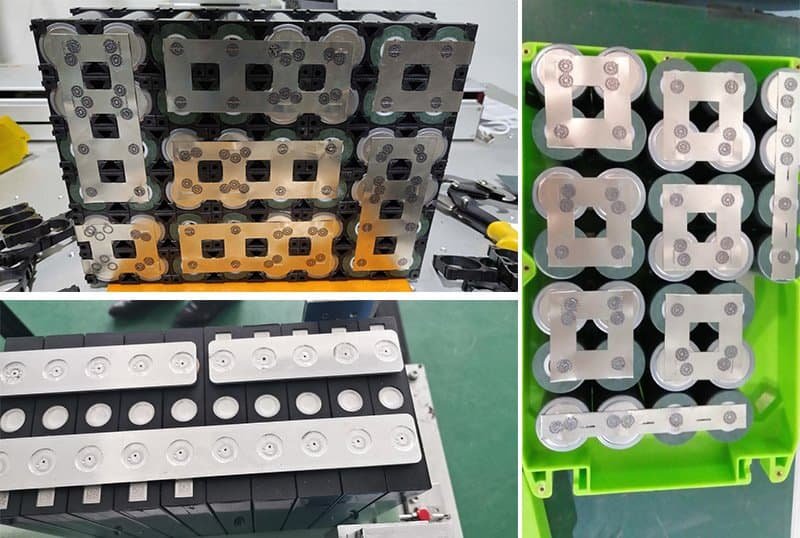

Battery industry: laser welding of lithium batteries, battery packs, electrodes, etc.

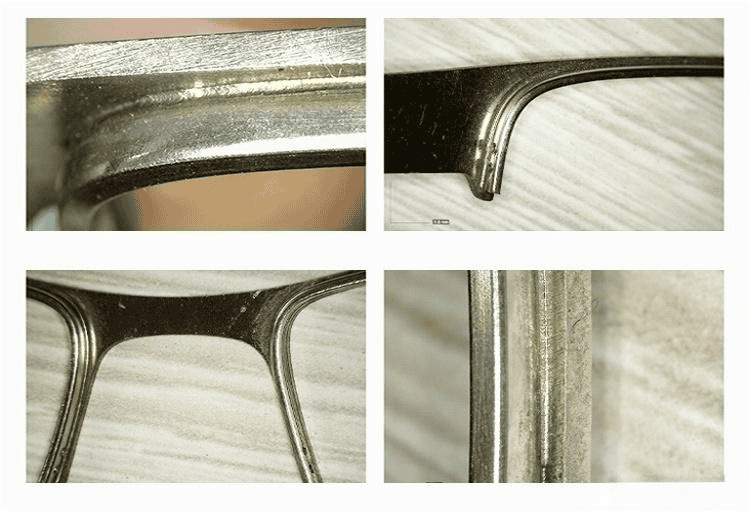

Glass industry: welding of glasses buckles and frames made of stainless steel, titanium alloy, etc.

Hardware industry: impellers, kettles, cups, stainless steel bowls, sensors, diodes, aluminum alloys, door handles, shelves, etc.

Service & commitment

After-sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms of payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.