What is a fully automatic stainless steel strip butt laser welding machine?

Laser welding involves radiating a high-intensity laser beam to the metal surface. Through the interaction between the laser and the metal, the metal absorbs the laser and converts it into heat energy, which melts the metal and then cools and crystallizes to form a weld.

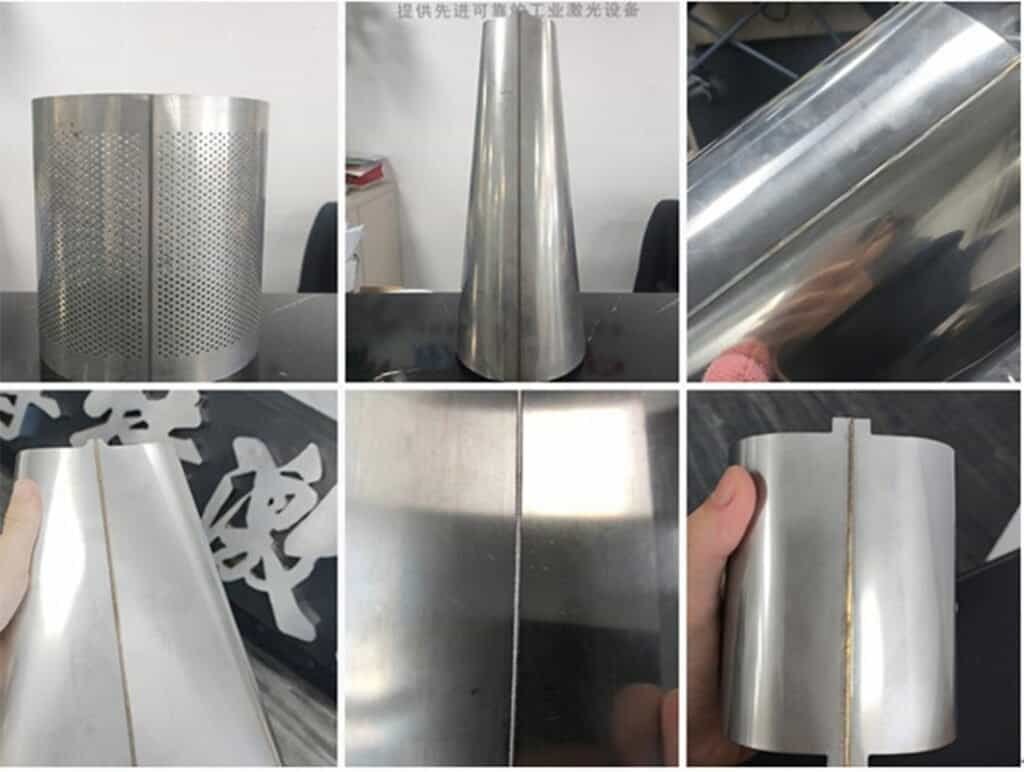

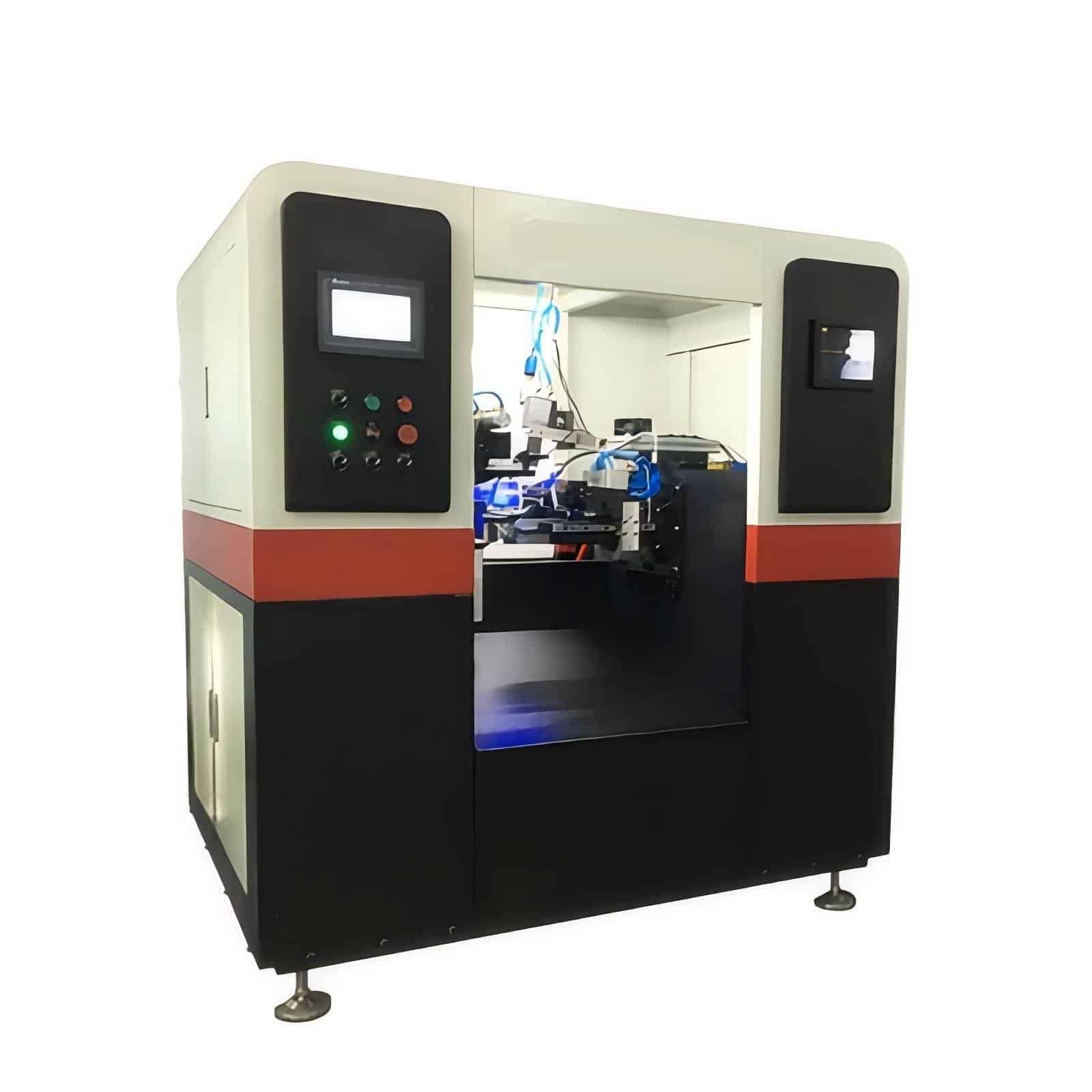

This machine uses continuous laser and is an efficient, high-performance laser welding equipment suitable for various metals and alloy materials. It has the characteristics of fast speed, considerable depth, and small deformation. This machine welds galvanized steel rings for glass cover guard rings, mesh screen baskets, trash cans, and enamel products. It mainly comprises a laser welding machine, a chiller, a fully automatic feeding and cutting system, a motion control system, a manipulator loading and unloading system, and a forming system.

Product Parameters

| Product Name | Stainless Steel Strip Butt Laser Welding Machine |

| Laser Power | 500W 1000W 1500W 2000W optional |

| Laser Source | Raycus MAX optional |

| Welding Head | WSX optional |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cooling System | Water Cooling |

| Voltage | 380V/3-Phase/50Hz/40A/60A |

Product advantages

◆ Fully automatic stainless steel strip laser welding machine is currently an advanced stainless steel welding equipment in China, with advantages such as simple operation and convenient maintenance;

◆ It has a stable and beautiful body structure, and its accessories are all world-renowned brands such as Delta, Raycus, MAX, and OMRON;

◆ High efficiency uses high-precision servo motors for feeding, high-speed pneumatic clamping, pushing, shearing, precise welding, automatic shedding of products, and one-stop, fully automatic production;

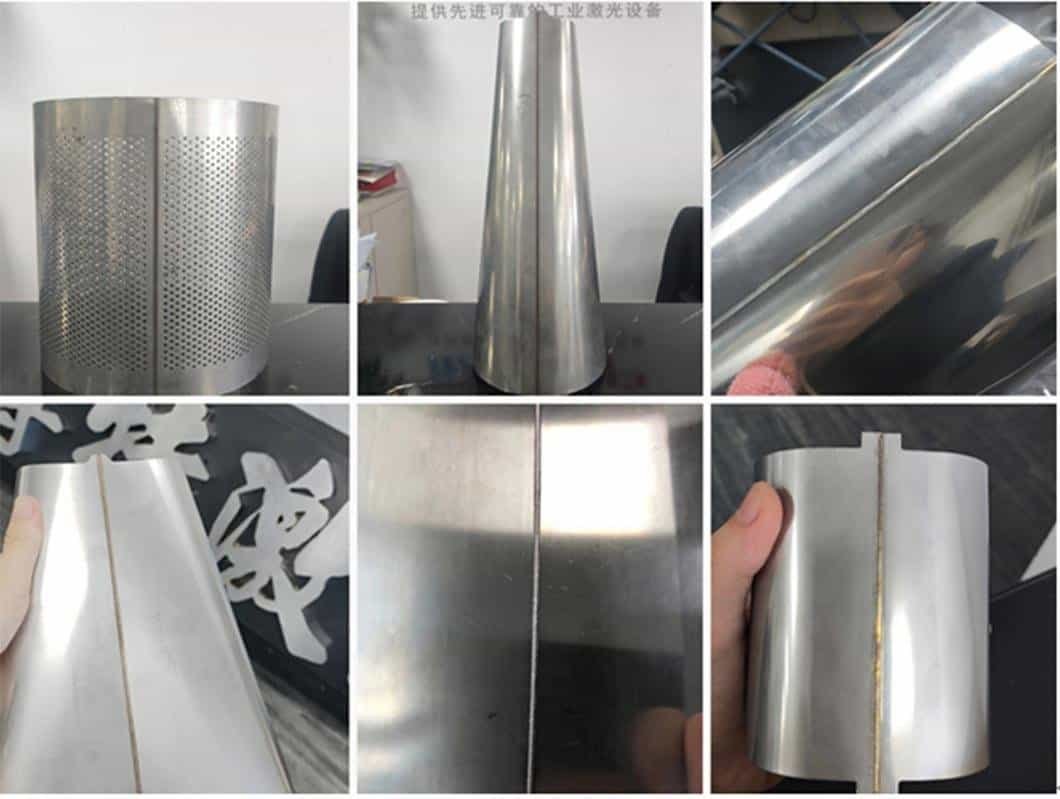

◆ High-quality product welds are greyish-white and require nitrogen protection. The surface is smooth and beautiful, without burrs. The welding strength can withstand 5mm of elongation, and no secondary elongation is needed; the desoldering rate is less than 0.1%;

◆ High energy-saving equipment has the function of automatic shutdown when there is no material or stuck alarm;

◆ Cost-effective enterprises are currently facing the dilemma of difficulty in hiring workers. This equipment combines multiple operation processes, and one worker can operate three welding machines simultaneously.

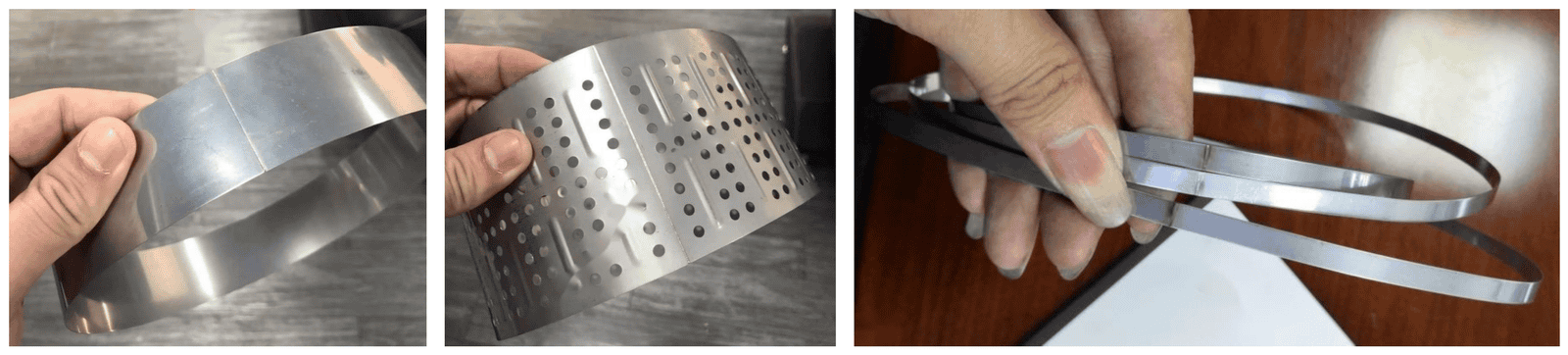

Applicable material size: Steel belt thickness: 0.18mm-2.5mm Steel belt width: 10mm-80mm Steel belt diameter: 120MM-650mm.

Fully Automatic Laser Welding Machine Vs Traditional Welding Machine

Fully automatic laser welding machine

Welding effect

The weld surface is beautiful and burr-free; no grinding or polishing is required.

Welding efficiency

The welding output is between 7000-9000 pieces per day in 8 hours, with high efficiency.

Welding defect rate

The defect rate can be controlled at 0.1%, and almost no defective products exist.

Production cost

Save labour: one worker can operate multiple devices to achieve fully automatic loading and unloading welding, and only ordinary workers must cooperate.

Grinding and polishing cost: No grinding and polishing is required, and there is zero cost.

The waste cost is meagre: calculated based on 10,000 pieces (10,000* 0.1% = 10), the number of defective pieces is about 10, and this waste cost is almost negligible.

Traditional Welding Machine

Welding effect

The weld is not smooth and needs to be polished.

Welding efficiency

A skilled worker can produce about 3,000 to 4,500 pieces 8 hours a day, with low production efficiency.

Welding defect rate

The manual defect rate can be as high as 1%- 5%—the wider the diameter of the steel strip, the higher the defect rate.

Production cost

Worker cost: skilled manual operation is required; one person can only manage one device. The worker cost is about twice that of a fully automatic laser welding worker.

Grinding and polishing cost: grinding and polishing are required, and the polishing cost ranges from a few cents to a dime per piece

High waste cost: calculated based on 10,000 pieces (10,000*1%=100-10,000*5%=500). The number of defective products is between 100 and 500 pieces, and the value of the steel strip depends on the material.

Welding Samples Display

Other models

| Product Name | Laser Straight Seam Welding Machine |

| Workpiece Size | 200/400/600/800/1000mm |

| Laser Power | 1000W/1500W optional |

| Laser Source | Raycus IPG JPT Max optional |

| Welding Head | WSX Ospri optional |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cooling System | Water Cooling |

| Voltage | 380V/3-Phase/50Hz/40A/60A |

Service & Commitment

After-Sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality Control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM Service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms Of Payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document Support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.