Are you planning to buy a 3 in 1 handheld laser welding machine? Our 3-in-1 (cleaning, cutting, welding) handheld welding head and control system have an automatic wire feeding function and can choose a variety of well-known laser brands and laser sources of different powers, which can realize spot welding, butt welding, lap welding, sealing welding, cleaning, cutting and other functions. It is lightweight and small, and the machine can move quickly. The laser transmission fiber is up to 15 meters long, which can realize lorealizeance operation. It has the advantages of simple operation, easy use, beautiful welds, fast welding speed, and no consumables. The whole machine is equipped with a unique cutting copper nozzle. After increasing the gas supply pressure, it can cut metal plates at will and realize polarisation and oxide layer removal. The scanning range is vast and adjustable. DG brand laser welding machine is worth your possession!

Product Advantages

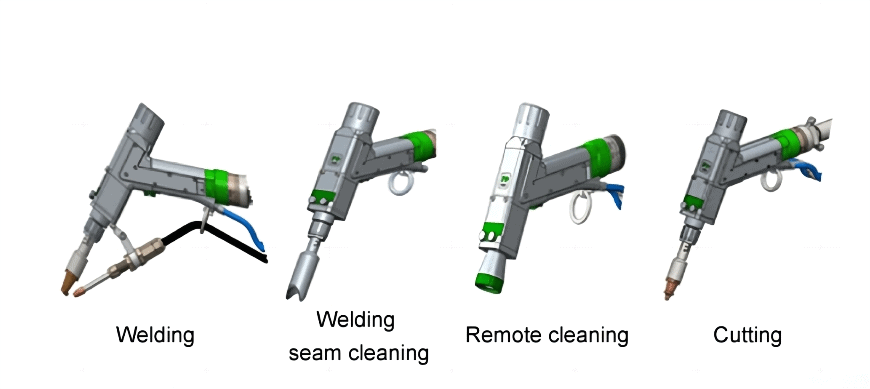

* Small body, with extensive functions, cutting, welding, cleaning, three functions can be switched at will with one button;

* Equipped with welding copper nozzles with different functions, wire feeding nozzles, V-shaped nozzles, and positioning nozzles so that welding different parts becomes a matter of will;

* Special cutting nozzle is used for the cutting function, with a small cutting gap and no burrs;

* Rust and oxide layers can be removed from various metal sheets;

* Small size cabinet of 620*585*400mm, with a smaller footprint, flexible and convenient;

* Equipped with a 10-meter-long optical fiber line, suitable for arc seam, straight seam, slope surface, inner corner, outer corner and any angle welding.

* Continuous welding, equipped with automatic wire feeder, beautiful welding spot with good quality, single-sided welding, double-sided forming, more solid welding, weld strength reaches or even exceeds the parent material itself;

* Low use and maintenance costs, monthly loss of parts less than $10;

* Fast welding speed, 2-3 times that of traditional welding, simple and easy to learn, easy to use, low technical threshold for operators, and more labour cost savings;

* Welding thin stainless steel plates, aluminium alloy plates, iron plates, galvanized plates, and other metal materials can perfectly replace traditional argon arc welding, electric welding, and other processes; it solves the problems of welding penetration, welding nodules, welding quality, etc. caused by argon arc welding.

Product Parameters

| Model | DG-HS1024 |

| Laser Power | 800W/1000W/1200W optional |

| Laser Wavelength | 1070nm |

| Welding Method | Continue |

| Welding Gap | ≤0.5MM |

| Welding Thickness | 0.5-8mm |

| Welding Speed | 0-120 mm/s |

| Working Humidity | <70% |

| Fiber Length | 10M-15M |

| Cooling Method | Air Cooling |

| Voltage | 220V/380V 50Hz |

Machine Size

Laser Head

Product Details

Laser source

World-famous brand, Max, Raycus, JPT……

Laser Head

The handheld light laser welding head weighs only 900g, making the operator work longer daily. It has double protective lenses, and the temperature sensor inside the laser head provides the most protection.

Wire feeder

Our wire feeding system supports a maximum of 3.0mm diameter metal wire, and the double motor inside the machine case gives the machine more stable support.

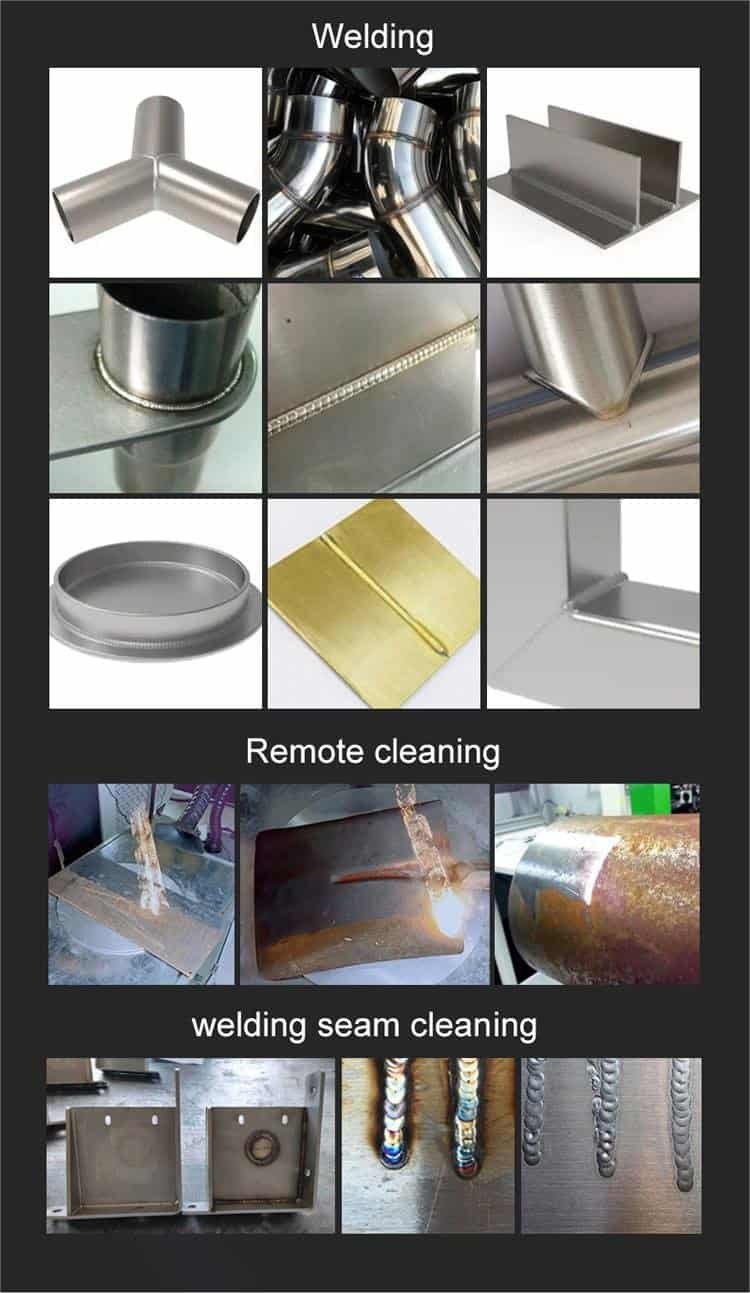

Sample Display

How do you choose a cost-effective handheld laser welding machine?

It is challenging to recruit welders, and good welders are even rarer. As we all know, the recruitment of welders in the sheet metal manufacturing industry is cumbersome. Many companies visit the talent market daily and cannot find good welders. Handheld laser welding does not require professional welders, and the welding speed is 5-10 times faster than traditional welders. One machine can save at least two welders a year, becoming a device that can replace traditional welders.

Industrial welding scene With the progress of science and technology, laser welding has become a new welding method in industrial applications such as new energy batteries and energy storage due to its high welding quality, small heat-affected area, and high flexibility. The emergence of handheld laser welding machines has brought users unprecedented flexibility, precision, and high efficiency, and it has rapidly developed into a large market with a compound growth rate of more than 30%.

However, many brands on the market have uneven quality. When purchasing a laser welding machine, people often don’t know where to start! Today, we will discuss the key factors when buying a cost-effective handheld laser welding machine.

1. Power selection: According to the material and thickness

Power is an essential parameter of a handheld laser welding machine, which directly affects the effect and efficiency of welding. Generally, the greater the power, the greater the welding speed and depth, and it is usually used to weld thicker metal materials, such as steel plates or aluminium alloys. Then, it is recommended to choose equipment with higher power (such as above 1000W) and equipment with lower power (such as 500W~800W) to meet the needs of thinner materials. In addition, different materials have different absorption efficiencies for lasers, and the characteristics of the materials need to be considered when choosing.

2. Operational flexibility: portability and ease of use

One of the advantages of handheld laser welding machines is flexibility, so choosing a device that is easy to carry and operate is particularly important. The lighter body and ergonomic handheld design will significantly reduce fatigue during long-term operation. At the same time, the equipment’s operating interface should be simple and intuitive so users can get started without complex training.

3. Compatibility and adaptability: multiple materials and welding methods

Different welding tasks may require switching between multiple materials, so the compatibility and adaptability of handheld laser welding machines are crucial. Choosing equipment that can handle a variety of metal materials (such as stainless steel, carbon steel, copper, aluminum, etc.) can significantly improve production flexibility. In addition, some high-end equipment also supports a variety of welding methods, such as deep melting welding, wire welding, etc., which can meet more complex welding needs.

4. Additional functions: flexible selection according to actual needs

Some handheld laser welding machines may provide additional functions, such as autofocus, welding parameter presets, working mode selection (welding, cutting, cleaning), etc. These functions can improve welding efficiency and quality but may also increase equipment costs. When choosing, the value of these additional functions should be weighed according to actual needs.

5. After-sales service and technical support: long-term considerations

As high-tech equipment, good after-sales service and technical support are essential to ensure regular operation and extend service life. When choosing, brands and suppliers that provide perfect after-sales service should be given priority, such as free installation and commissioning, training services, regular maintenance and timely technical support. By establishing a long-term cooperative relationship with suppliers, problems encountered during the use of equipment can be effectively avoided.

6. Cost-effectiveness: return on investment

When choosing a handheld laser welding machine, in addition to paying attention to the price of the equipment itself, you also need to consider its comprehensive cost-effectiveness. The purchase cost of the equipment, the cost of consumables, the maintenance cost, and the improvement of production efficiency are all important factors affecting the return on investment. Choosing cost-effective equipment can effectively control costs and achieve a higher return on investment while improving production efficiency.

Other Types (optional)

| Model | DG-1000 | DG-1500 | DG-2000 | DG-3000 |

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Source | Raycus/Max/IPG | Raycus/Max/IPG | Raycus/Max/IPG | Raycus/Max/IPG |

| Laser Head | 3 IN 1 | 3 IN 1 | 3 IN 1 | 3 IN 1 |

| Fiber Wire Length | 10 Meters | 10 Meters | 10 Meters | 10 Meters |

| Laser Wavelength | 1070nm | 1070nm | 1070nm | 1070nm |

| Operate Mode | Continuation/Modulate | Continuation/Modulate | Continuation/Modulate | Continuation/Modulate |

| Water Chiller | Hanli | Hanli | Hanli | Hanli |

| Spot Adjusting Range | 0.1-3mm | 0.1-3mm | 0.1-3mm | 0.1-3mm |

| Repeating Precision | ±0.01mm | ±0.01mm | ±0.01mm | ±0.01mm |

| Cabinet Size | 744*941*1030mm | 744*941*1030mm | 750*1260*1110mm | 750*1260*1110mm |

| Machine Weight | About 200KG | About 200KG | About 220KG | About 220KG |

| Voltage | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V | 110V/220V/380V |

| Model | DG-HS1500 |

| Laser Beam | World-famous brand, Max, Raycus, JPT…… |

| Cooling | Built-in Industrial Chiller(Purified water or distilled water) |

| Cable length | Fiber cable length 10m, Operable cable length 8m |

| Weld Head | Handheld swinging welding head, cleaning mode, cutting mode, six welding modes, replaceable nozzles to adapt to different welding processes |

| Wobble width | Adjustable 0-5mm |

| Protection Gas | Argon/Nitrogen Pressure 5-10L/min |

| User Interface | For Laser Control: Power, Frequency, Duty cycle. Motor control: working mode, Frequency, Spot width. Gas control: Advance, Delay, Proportion |

| Language | Chinese-English-Russian-Korean-Vietnamese |

| Safety | Class 4 laser equipment, Machine with CE and FDA certificate. The machine has an error alarm function, emergency stop, and chiller alarm. |

| Power Requirement | 220±10% V AC, 50/60Hz CUSTOMIZATION |

| Operating Ambient Temperature(℃) | 10~40℃ |

| Humidity (%) | 70 |

Service & Commitment

After-Sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality Control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM Service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms Of Payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document Support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.