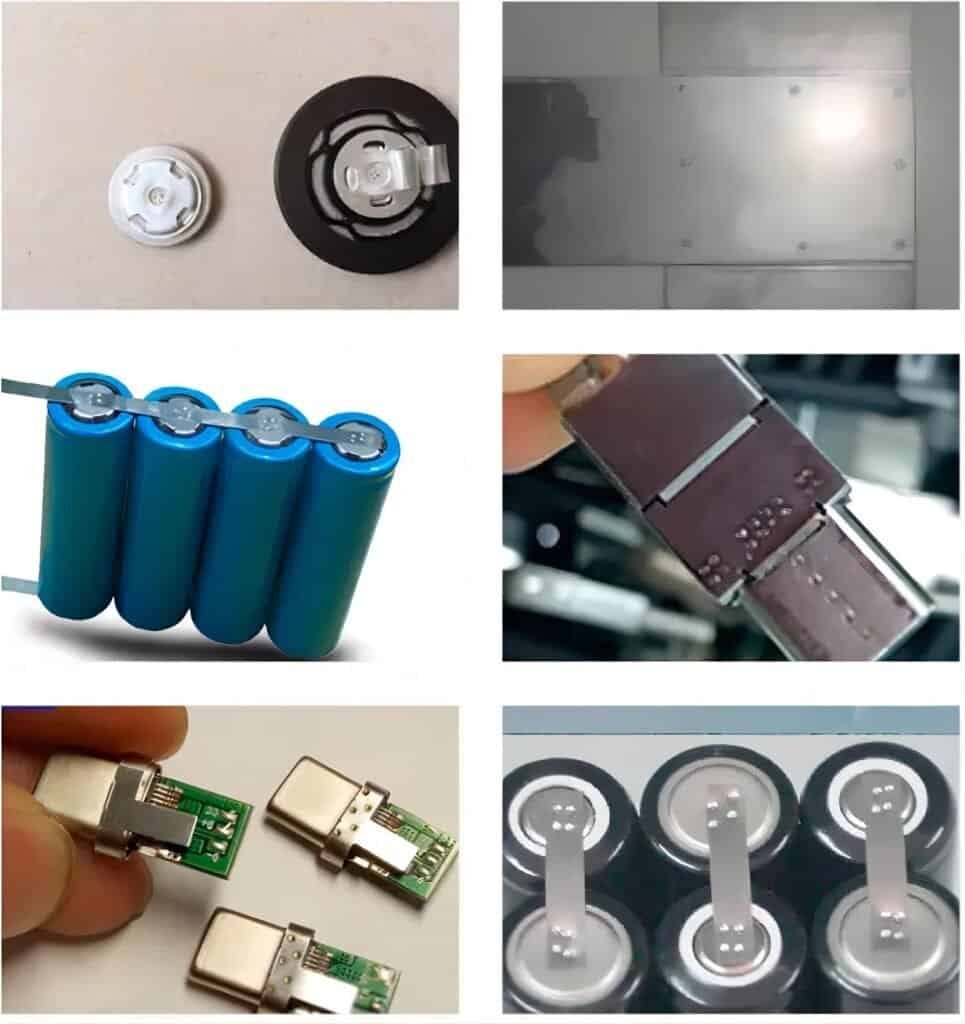

Are you looking for a lithium battery laser welding machine? Please explore the most popular and affordable DaG brand lithium battery laser welding machines. DaG lithium battery laser welding machine is mainly used for new energy lithium battery pack welding: lithium battery to nickel, explosion-proof valve welding, battery ear welding, battery pole spot welding, battery pole welding, power battery shell and cover sealing welding, large single square shell lithium battery and large polymer power battery module and pack welding, etc., which can provide more complete automatic welding solutions for enterprises that need new energy lithium battery welding equipment.

The equipment integrates a fiber laser source, a PC industrial computer system, a red light indicator, and a constant temperature chiller. It can perform point, line, pattern, and array welding. It has high precision and good beam quality and is suitable for welding thin metal sheets like nickel and stainless steel. It has excellent weld quality and is widely used in lithium battery manufacturing.

How to use laser welding technology in lithium battery welding?

With the continuous development of science and technology, lithium batteries are increasingly used in various fields, such as mobile phones, laptops, power tools, electric bicycles, and electric vehicles. Lithium batteries have the advantages of small size, lightweight, high energy density, and low self-discharge rate, making them ideal energy storage devices. However, the safety and reliability of lithium batteries are crucial to their performance and service life.

Laser welding technology focuses on the high-energy laser beam generated by the laser between the positive and negative electrodes of the lithium battery. It controls the laser power and speed so that the weld between the positive and negative electrodes melts and forms a continuous weld. This welding method has the advantages of high precision, fast speed, and low heat impact, which can effectively improve the safety and reliability of lithium batteries.

Cylindrical lithium battery laser welding machine

Technical Parameters

| Model: | DG-100W-600W | Laser Classification: | Optical Fiber Laser |

| Type: | QBW | Name: | Laser Welding Machine |

| Fiber Cable Length: | 2M | Laser Power: | 100W/150W/300W |

| Welding Head: | GALVO | Laser Source: | QCW |

| Gross Power: | <4kw | Positioning: | Red light |

| Spot adjusting range: | 0.1-3mm | Repeating precision: | ±0.01mm |

| Laser Wavelength: | 1080nm | Voltage: | 220/380V 50/60HZ |

| Transport Package: | Wood Package | Specification: | Support custom size |

Products Feature

X Y Z Axis support

The laser consumes little power and can expand the X and Y motion axes and the welding range.

Homemade software

Professional welding software is simple to operate and easy to use. It can perform arbitrary welding of points, lines, circles, and straight-line graphics.

High efficiency

The galvanometer welding efficiency is over three times that of ordinary laser spot welding machines.

Stability

The laser has high stability, adjustable power, and is maintenance-free daily.

Laser welding machine for prismatic lithium battery pack

Technical Parameters

| Product Name | Automatic Laser Welding Machine |

| Laser Power | 1000W-6000W optional |

| Laser Source | Raycus optional |

| Welding Head | WSX optional |

| Laser Wavelength | 1070nm |

| Pulse Width | 0.5-15ms |

| Pulse Frequency | ≤100Hz |

| Spot adjusting range | 0.1-3mm |

| Repeating precision | ±0.01mm |

| Cooling System | Water Cooling |

| Voltage | 220V/380V 3-Phase/50Hz/40A/60A |

★★★ Suitable for welding nickel plates, aluminum, copper, stainless steel, and other metal plates. High precision, good solder joint quality effect.

★★★ Widely used in lithium battery manufacturing.

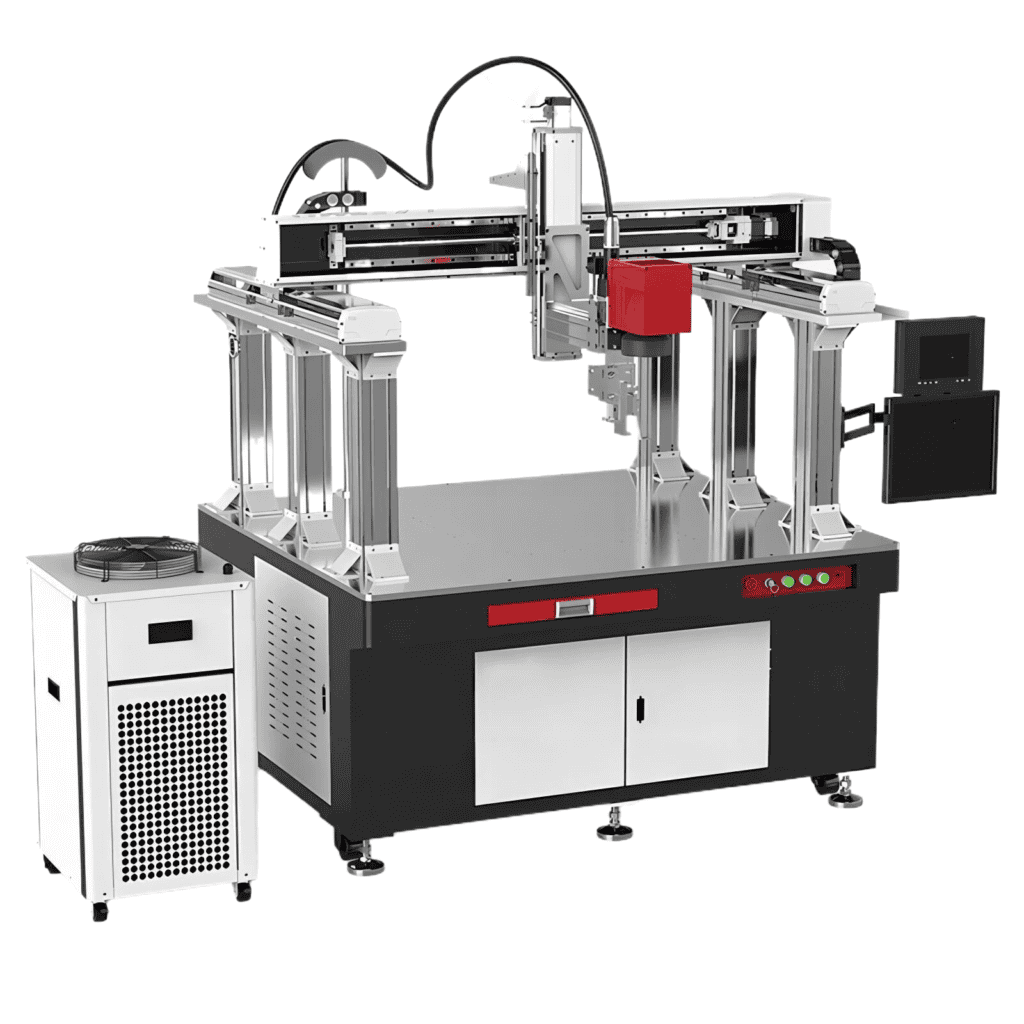

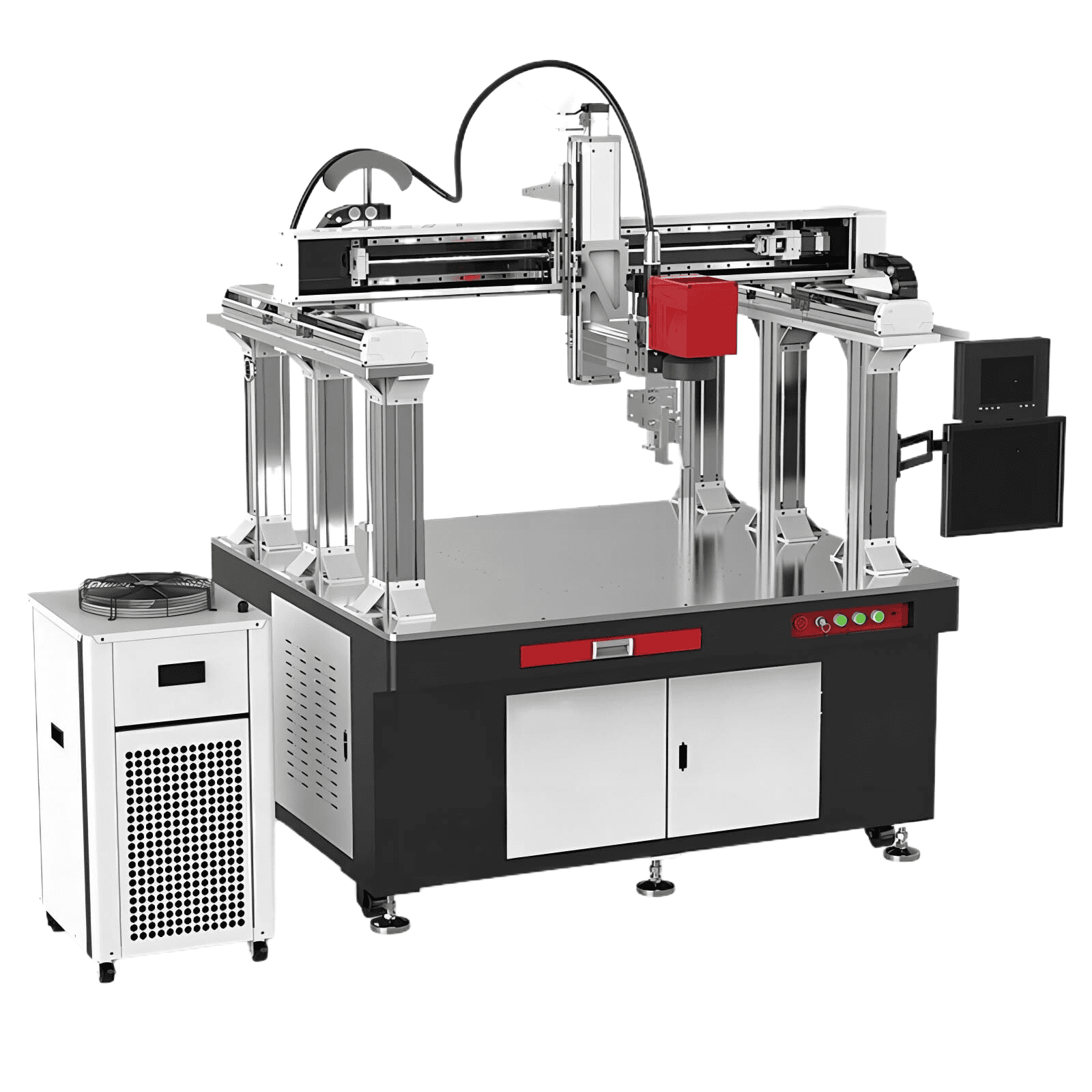

Automatic large-area gantry lithium battery laser welding machine

Technical Parameters

| Model: | DG-1000W-6000W | Laser Classification: | Optical Fiber Laser |

| Type: | Optical Fiber Transmission Laser Welding Machine | Name: | Laser Welding Machine |

| Fiber Cable Length: | 8M | Laser Power: | 1000W/1500W/ 2000W /3000W /6000W |

| Welding Head: | WSX Raytools optional | Laser Source: | Raycus IPG JPT Max optional |

| Gross Power: | <8kw | Positioning: | Red light |

| Spot adjusting range: | 0.1-3mm | Repeating precision: | ±0.01mm |

| Pulse Width: | 0.5-15ms | Pulse Frequency: | ≤100Hz |

| Welding Head: | Double Wobble Welding Head | Laser Focus: | 200mm |

| Laser Wavelength: | 1080nm | Voltage: | 220/380V 50/60HZ |

| Transport Package: | Wood Package | Specification: | Support custom size |

Product Features

The equipment adopts a 1000-6000W fiber laser with high photoelectric conversion efficiency and long laser life. It has a three-axis linkage working platform and an automatic lifting laser beam. The welding software under the Windows system allows for freely modifying the welding path, making it easy to operate and maintain.

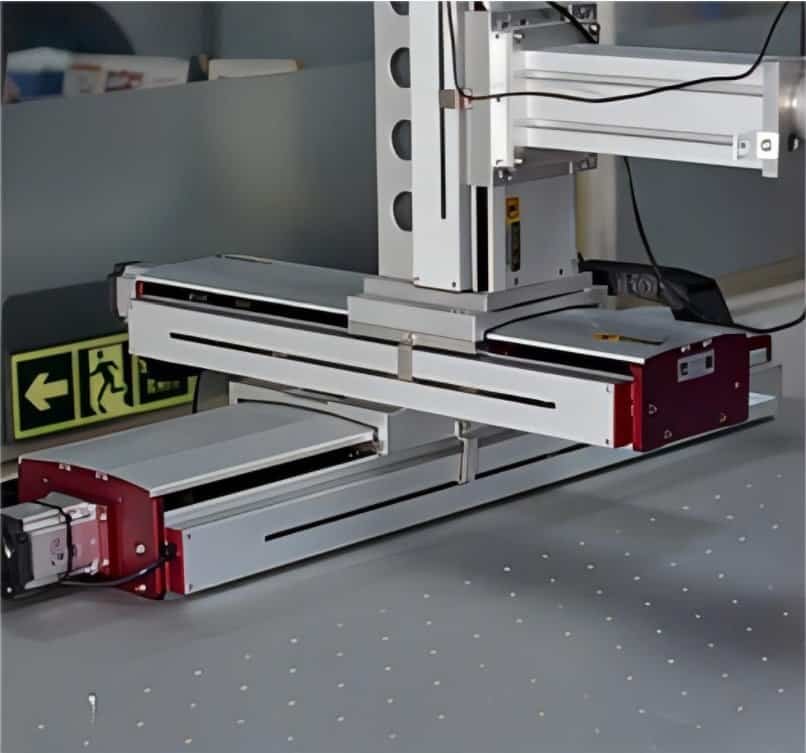

X Y Z Axis standard 500*300*400mm or bigger size

XYZ axis module structure, fast response speed, high precision, and welding to conceal the Pack requirements.

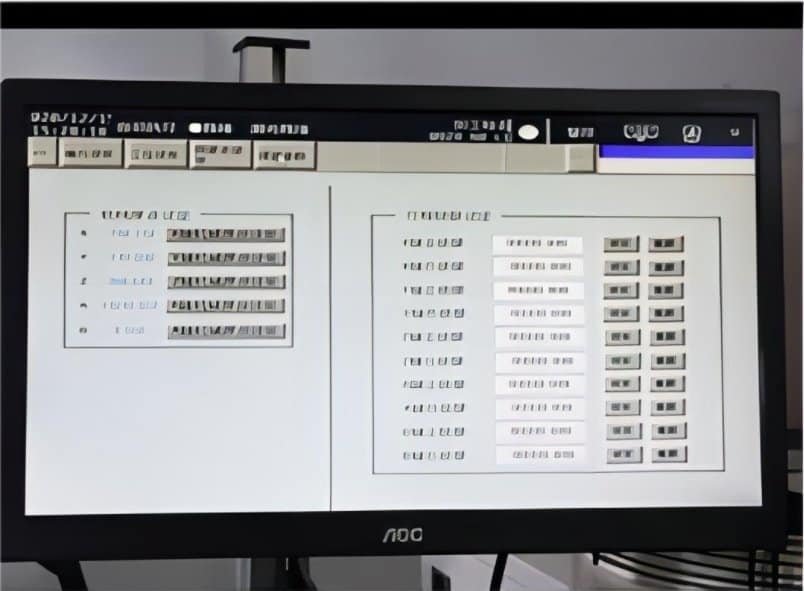

DSP software

Professional welding software is simple to operate and easy to use. It can be used for arbitrarily welding points, straight lines, circles, releases, and other plane graphics.

I/O interface

The I/O interface is reserved for expansion, which can cooperate with the linkage of an electrical automation device and is equipped with a CCD display and monitoring function.

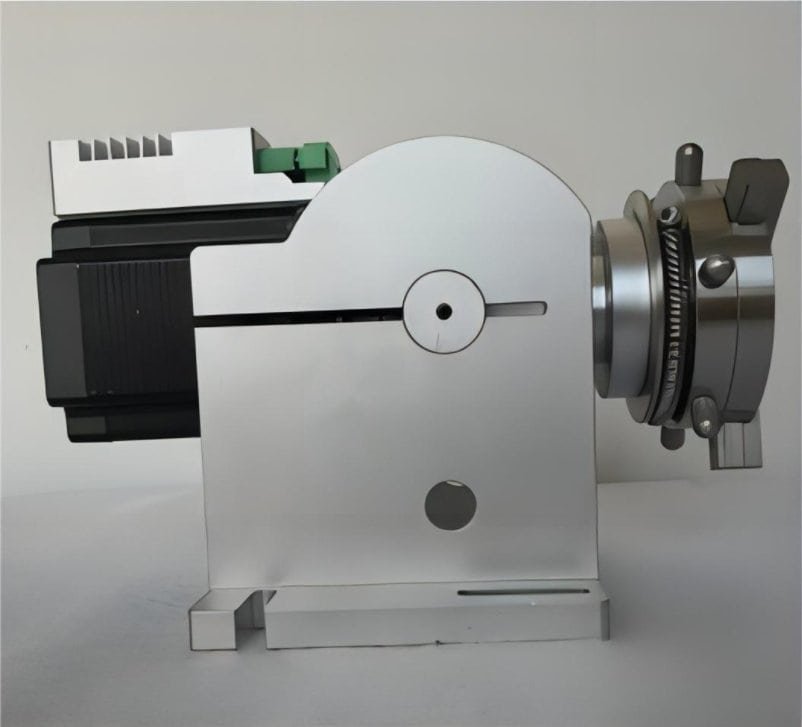

Swing welding head

It can be equipped with a swing welding head, which is compatible with soft battery welding, and can meet the higher welding process of the product.

Product Details

X.Y.Z Axis Guide Rail

With moving up and down, it can weld irregular products. The Z-axis has a brake function.

Laser Welding Head

It adopts the Industrial Standard QBHConnector, connects to the fiber laser, and provides standard fibre access. It has High welding precision, outstanding durability, and easy maintenance and adjustment.

Laser Source

With the advanced fiber laser generator, we can achieve 200% higher efficiency, 100% sealability after welding, and 50% lower consumable costs than YAG lasers.

CCD Camera Display

Display on a video display by connecting the device, Clearwelding point.

Special Welding Software

It functions as a continuous laser beam and has an adjustable output waveform, which can ensure precious and high-speed welding.

Custom Fixture

It can weld round tubes, square tubes and other different shapes. (Optional device).

Water Chiller

It has a 1.5P water chiller with a fast cooling effect, supporting continuous working.

Advantages of laser welding lithium batteries

1. High energy density, small welding deformation, and small heat-affected zone can effectively improve the precision of parts; the weld is smooth and free of impurities, uniform and dense, and no additional grinding is required;

2. It can be precisely controlled, with a slight focus spot high-precision positioning, and easy to automate with a robotic arm, improving welding efficiency, reducing working hours, and reducing costs;

3. When welding thin plates or thin-diameter wires, it will not be as susceptible to remelting as arc welding;

In addition, the battery structure usually contains various materials, such as steel, aluminium, copper, nickel, etc. These metals may be made into electrodes, wires, or shells; therefore, whether welding between one or multiple materials puts forward high requirements for the welding process. The advantage of laser welding is that it can weld a wide variety of materials and can achieve welding between different materials.

Application prospect

Lithium batteries have become increasingly widely used in modern life as a new type of energy. Welding is an indispensable link in the manufacturing process of lithium batteries. However, traditional welding equipment has many problems, such as easy deformation and uncomplicated fracture of solder joints. Therefore, the lithium battery laser welding machine has gradually become an essential technology in manufacturing lithium batteries.

Laser welding technology of lithium batteries has a broad application prospect in lithium battery manufacturing. It can connect electrodes, end plates, connecting strips, and other parts and manufacture solar panels, LED lights, and other devices. With the continuous development of technology, the price of laser welding machines is also gradually decreasing, promoting their broader use in future applications.

Service & commitment

After-sale

We provide a 1-3 year warranty and lifetime maintenance for our products. During the warranty period, any functional defects (excluding artificial or force majeure factors) can be repaired or replaced free of charge (except for wearing parts). After the warranty period, we will charge for the workpiece based on the actual situation.

Quality control

A highly skilled and rigorous quality inspection team is employed during the material procurement and production.

Our quality control strictly tests 100% of all finished machines we deliver to engineering departments.

We will offer the customer detailed machine pictures and test videos before delivery.

OEM service

Thanks to our extensive experience, custom and OEM orders are warmly welcomed. All OEM services are free. Customers only need to provide us with their logo drawing, functional requirements, colours, etc.

There is no minimum order quantity required.

Privacy

Your personally identifiable information (such as your name, address, email address, banking information, etc.) will not be disclosed or shared with any third party.

All inquiries, questions, or requests for assistance will be responded to within 24 hours, even during holidays. If you have any urgent questions, please call us.

Terms of payment

A 30% T/T down payment is required, and the balance should be paid before shipment.

Other payment terms are PayPal, Western Union, etc.

Document support

All documents supported for customs clearance: contracts, packing lists, commercial invoices, export declarations, etc.

Reviews

There are no reviews yet.