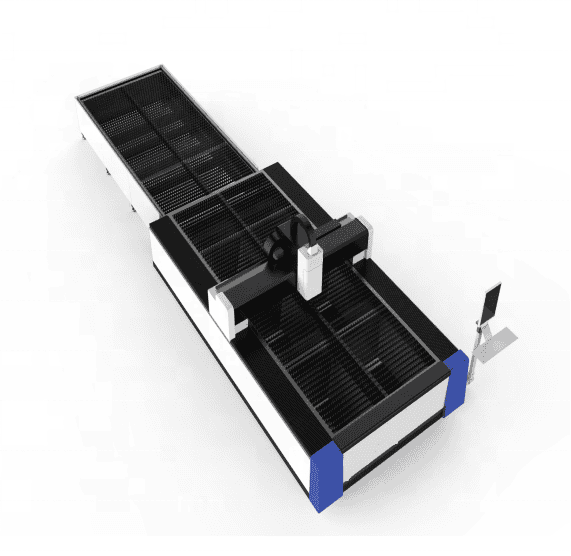

Exchange Platform Laser Cutting Machine Analysis

Exchange platform roles

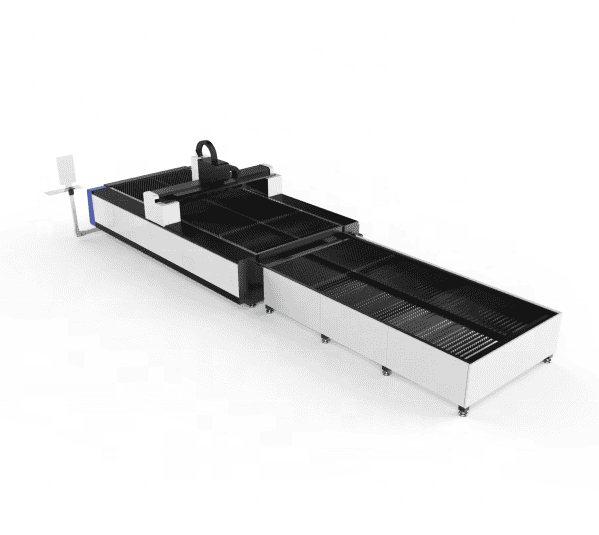

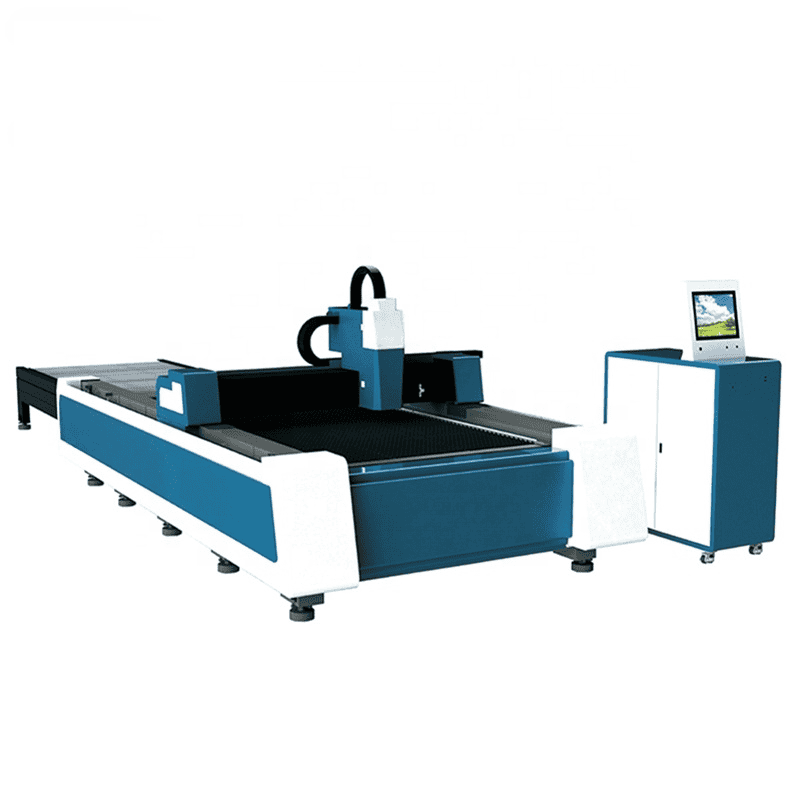

A laser cutting machine exchange platform is a technical means to optimize production efficiency. When carrying out large-scale or batch production, it is usually necessary to use several workbenches alternately to complete the work more efficiently. While one workbench is cutting, another can prepare materials or clean up waste generated during the cutting process. This can significantly improve production efficiency and minimize production time and cost.

How the exchange platform works

1. Preparation

Before starting to process the workpiece, place the workpiece to be cut from the inlet conveyor system onto the exchange platform. Then, the workpiece can be accurately positioned on the exchange platform (using the up and down position control system) to be accurately cut during laser cutting.

2. Cut the workpiece

The exchange platform will automatically move when cutting the workpiece, moving the workpiece under the laser cutting head for easy cutting. The laser cutting head will cut the workpiece according to the pre-set program and leave the workpiece on the exchange platform after cutting.

3. Exchange the workpiece

When cutting is completed, the exchange platform automatically moves to the position of the outlet conveyor system and moves the workpiece to the next process position.

4. Repeat the process

Repeat the above steps until all workpieces have been produced.

Product Parameter

| No. | Type | DG-1530F | DG-1540F | DG-2040F | DG-1560F | DG-2060F | DG-2560F | |

| 1 | Max Cutting Size (mm) | 1500×3000 | 1500X4000 | 4000×2000 | 1500×6000 | 2000×6000 | 2500×6000 | |

| 2 | Max Height of The Workpiece (mm) | 90 | 90 | 90 | 90 | 90 | 90 | |

| 3 | Effective Travel | X-Axis (mm) | 1505 | 1505 | 2005 | 2005 | 2005 | 2505 |

| Y-Axis (mm) | 3005 | 4005 | 4005 | 6005 | 6005 | 6005 | ||

| Z-Axis (mm) | 150 | 150 | 150 | 150 | 150 | 150 | ||

| 4 | Positional Accuracy | X-Axis (mm) | ±0.04 | ±0.04 | ±0.04 | ±0.04 | ±0.04 | ±0.04 |

| Y-Axis (mm) | ±0.04 | ±0.04 | ±0.04 | ±0.04 | ±0.04 | ±0.04 | ||

| Z-Axis (mm) | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ||

| 5 | Repeated Positioning Accuracy | X-Axis (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| Y-Axis (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ||

| Z-Axis (mm) | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ||

| 6 | Re-positioning Speed | X-Axis (m/min) | 110 | 110 | 110 | 110 | 110 | 110 |

| Y-Axis (m/min) | 110 | 110 | 110 | 110 | 110 | 110 | ||

| Z-Axis (m/min) | 110 | 110 | 110 | 110 | 110 | 110 | ||

| 7 | Accelerated Speed (G) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| 8 | Level of Protection | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | |

| 9 | Total Weight(KG) | 5200 | 5900 | 6400 | 7600 | 7900 | 8100 | |

| 10 | Boundary Dimension L×W×H(mm) | 4600X3200X1800 | 5600X3200x1800 | 5600x3400x1800 | 7700x2900x1800 | 7700x3400x1800 | 7700x3600x1800 | |

Exchange Platform Laser Cutting Machine Advantage

It adopts an up-and-down exchange platform. The converter controls the exchanging motor, and the machine can finish the platform exchange within 15 seconds—less load time and more efficiency, stability, and speed.

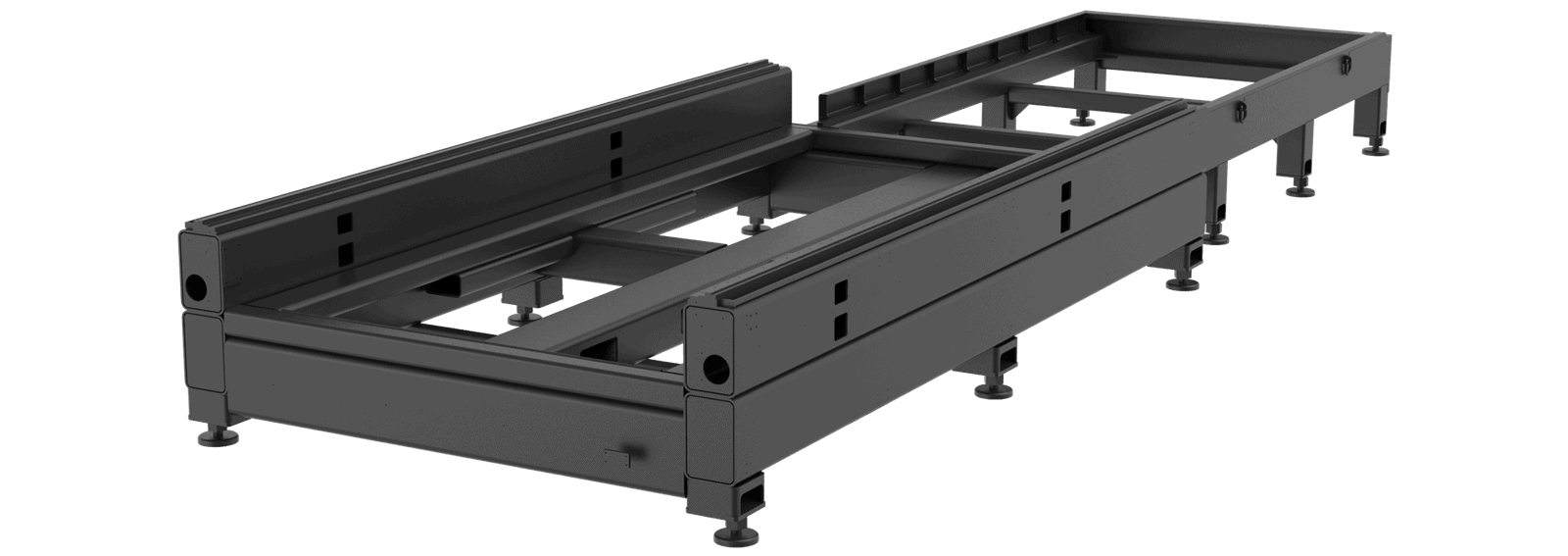

The internal structure of the bed adopts the aircraft metal honeycomb structure, which is welded by several rectangular tubes. Stiffeners are arranged inside the tubes to increase the bed’s strength and tensile strength, and the resistance and stability of the guide rail are improved to avoid the bed’s deformation effectively.

High strength, stability, and tensile strength ensure 20 years of use without distortion. The rectangular pipe wall is 10mm thick and weighs 4300 kg.

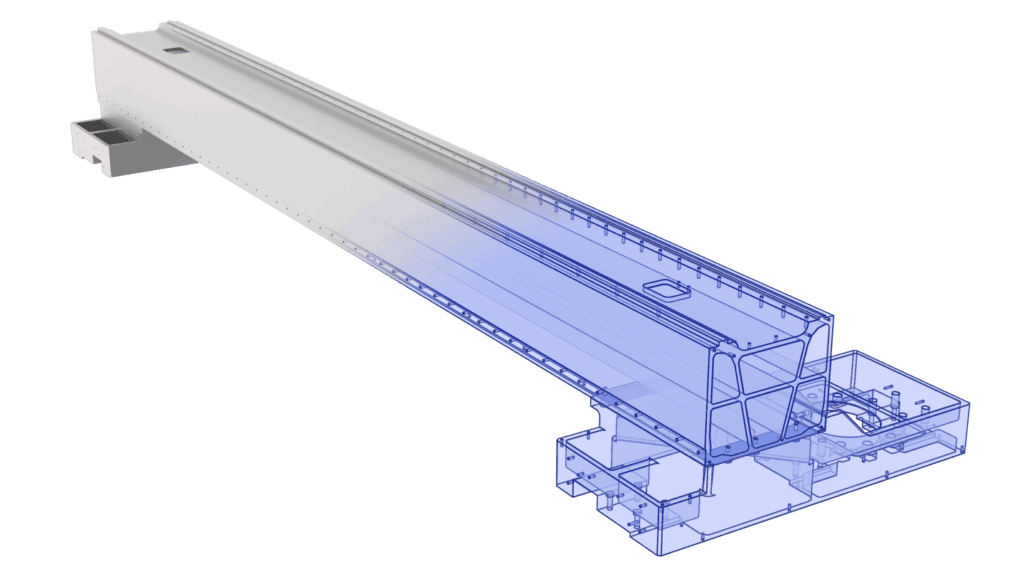

Cold-drawn Extruded Aluminium Beam

The first manufacturer used cast aluminium beams supported by 10-ton steel moulds, which are more rigid. The weight is half that of traditional welding iron gantries.

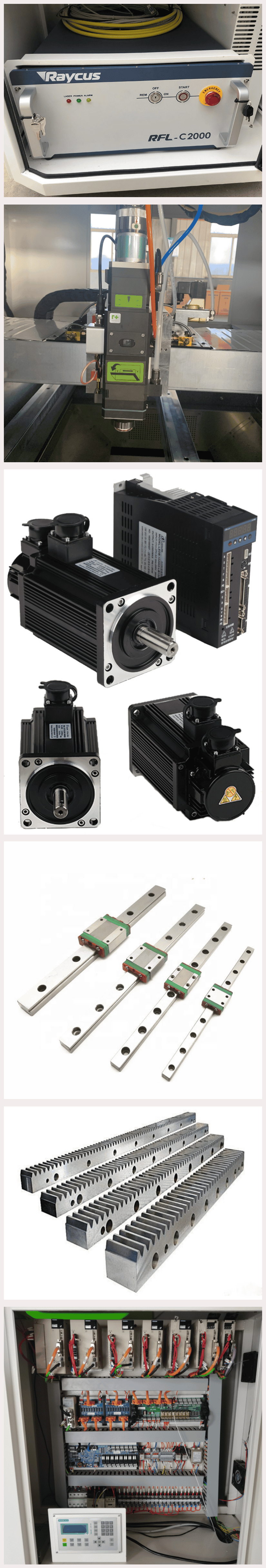

Configuration List

| Parts | Optional Brand | Advantage |

| Control System | Cypcut / Au3tech /NCStudio | Domestic professional and widely used laser cutting system |

| Laser Source | Raycus/ Max /IPG/ N-light | Long life, efficient and safe |

| Laser Cutting Head | Raytools/Au3tech | Stable, long life, easy replacement of lossy parts, simple focus adjustment, optical components imported from Germany |

| Dust Removal Fan | Powerful dust removal fan | Bass, powerful, good dust extraction effect |

| Bed Working Size | 3000*1500mm/other | Suitable for most standard metal plates |

| Precision Gear Rack | YYC | High precision, high hardness and small error |

| Precision Linear Guide | HIWIN / THK | Original imported guide rail, high precision, stable, long life |

| Gear Reducer | MOTOREDUCER | 48 hours of ageing annealing to remove the effect of thermal stress on the machine tool |

| Servo Motor | Yaskawa/Panasonic/delta | The original imported servo system has high precision, stability, long life, and large domestic consumption. |

| Air Control | SMC | Imported high temperature and low-pressure proportional valve, Stable high and low-pressure switching, more stable cutting |

| Laser protective glasses | one pair | Standard |

| Protective lenses | five pieces | Standard |

| Toolbox | one set | Standard |

| Operation manual | one | Standard |

| Cutting software U disk | one | Standard |

| nozzle | 5-10 | Standard |

| Product certification | one | Standard |

Application

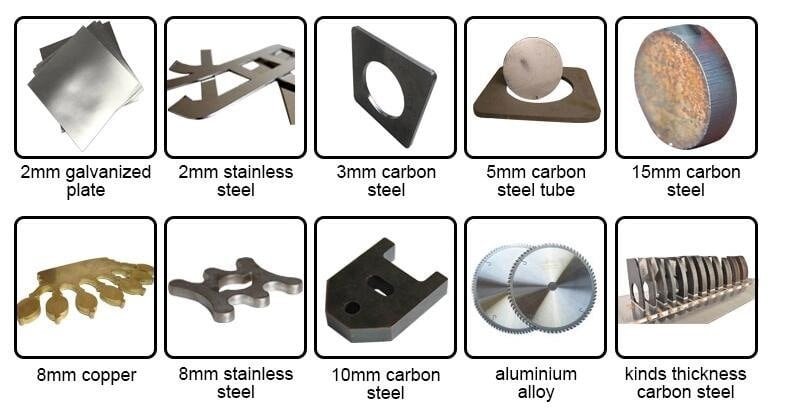

Applied materials:

It is mainly used for cutting carbon steel, silicon steel, stainless steel, aluminium alloy, titanium alloy, galvanized steel sheet, pickling board, aluminium zinc plate, copper, and many other materials.

Applied Industries:

Fibre laser cutting machines applied in sheet metal processing, aviation, spaceflight, electronics, electrical appliances, subway parts, automobiles, machinery, precision components, ships, metallurgical equipment, elevators, household appliances, gifts and crafts, tool processing, adornment, advertising, metal foreign processing various manufacturing processing industries.

DAG At Your Service

Pre-Sales Service

• Free sample cutting service:

For free sample cutting/testing, please send us your CAD file (PLT, AI) or mail us your workpiece; we will cut it in the factory and make a video to show you the cutting process and results or send you a sample to check the cutting quality.

• Drive solution design:

According to the customer’s product processing requirements, we can design a unique solution for customers to support higher manufacturing efficiency and better processing quality.

• Customized machine design:

We can modify our machines according to the customer’s application to achieve customer convenience and high production efficiency.

After-Sales Service

• As a professional CNC laser manufacturer and supplier, DAG will provide English training videos and user manuals for fiber laser machine installation, operation, maintenance and troubleshooting, and provide you with English training videos and user manuals by email, phone, mobile phone, etc. when you encounter installation, operation or adjustment problems.

• You can come to our factory for training. We will provide professional guidance and direct face-to-face practical training. We have assembly equipment, various tools and testing equipment here. Training time: 3~5 days (recommended).

• Our engineers will visit your local site for on-site guidance and training services. We must assist with visa processing and prepay travel and accommodation expenses before deployment and during service.

Warranty

• Three-year warranty for the whole machine, 18-month warranty for the laser, 12-month warranty for the chiller, and no warranty for the lens/mirror/nozzle.

• Long-term lifetime maintenance: The after-sales department will provide 24/7 English online support.

• We are responsible for providing free accessories during the warranty period, except for artificial damage.

• After the warranty period, the buyer is only responsible for the actual repair costs.

Frequently Asked Questions

If you need a free quote and detailed solution, please answer the following questions and let us know by email so that we can recommend the most suitable machine and quote you an affordable price.

• Do you need to cut metal plates, tubes, or both?

• If you need to cut tubes, what is the length, diameter, and maximum thickness of your tubes?

• What is the maximum working area required for cutting metal plates?

• How much do you plan to budget for customizing the machine?

• What will the processed material be used for (applicant)

• Which seaport is closest to you?

• Do you have experience with laser cutting?

• What is your online chat method, such as Skype, WhatsApp or WeChat

• Are you an end user or a dealer?

Reviews

There are no reviews yet.